Partial unbonded grouting corrugated pipe prefabricating, assembling and connecting structure and construction method

A prefabricated assembly and connection structure technology, applied in the direction of basic structure engineering, structural elements, building components, etc., can solve the problems of unsuitable application of bridge piers, low ductility performance and energy dissipation capacity, so as to facilitate popularization and application, improve ductility performance and Energy-dissipating ability and effect of improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In the embodiment of the present invention, the pre-construction preparations are: according to the design drawings, the construction site is cleaned up, and construction materials, machinery, and personnel are arranged to be in place.

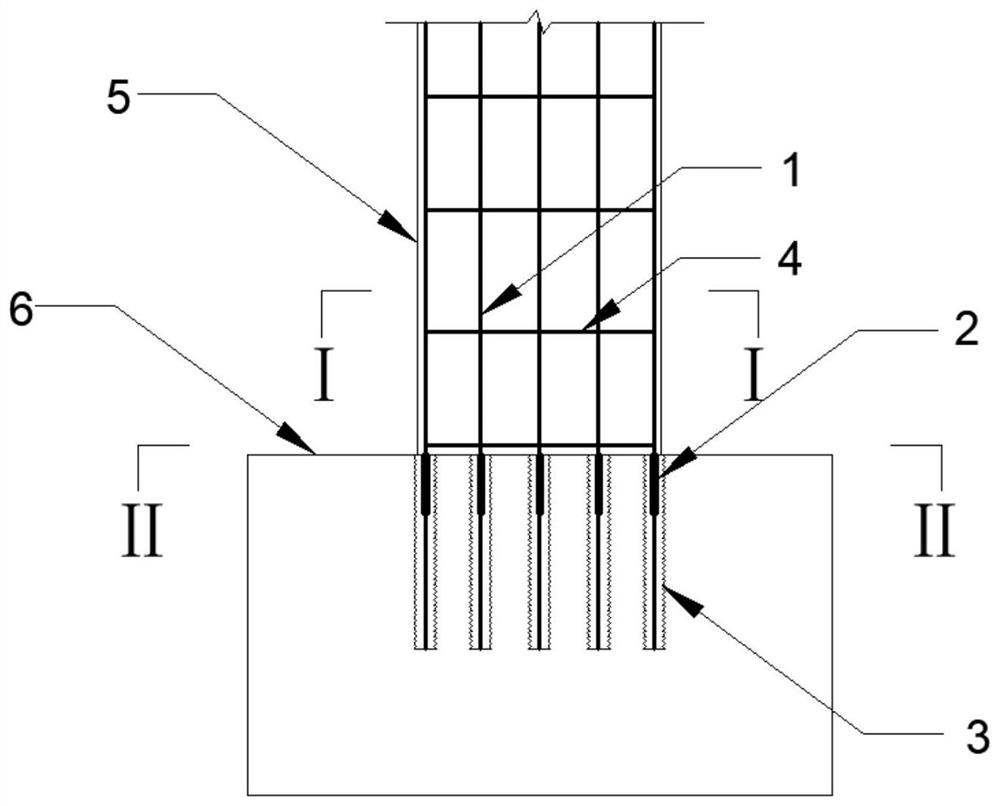

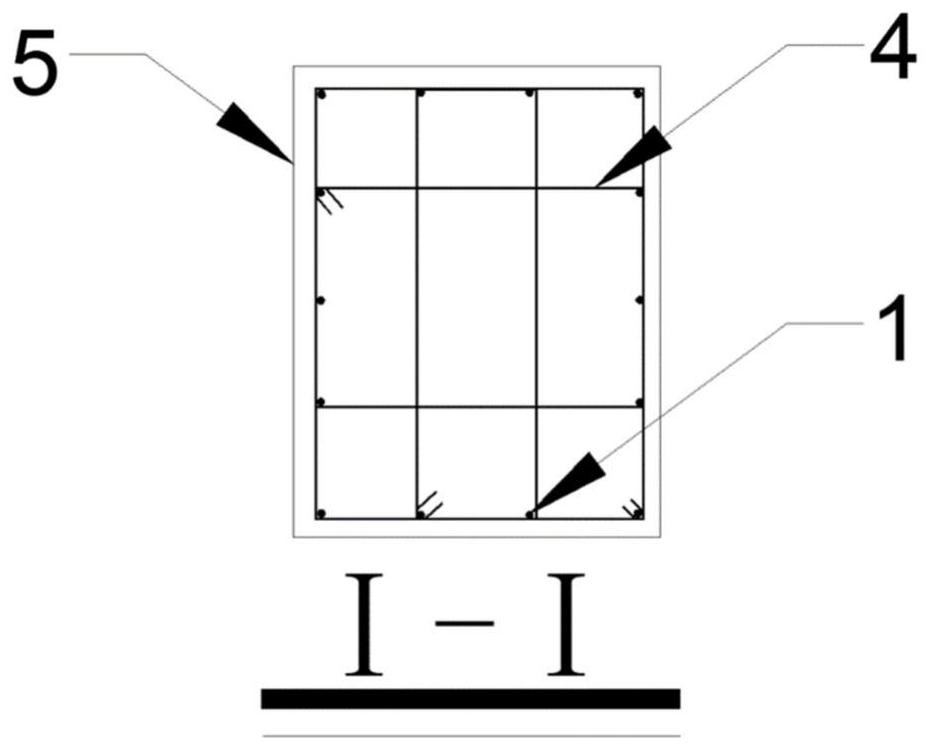

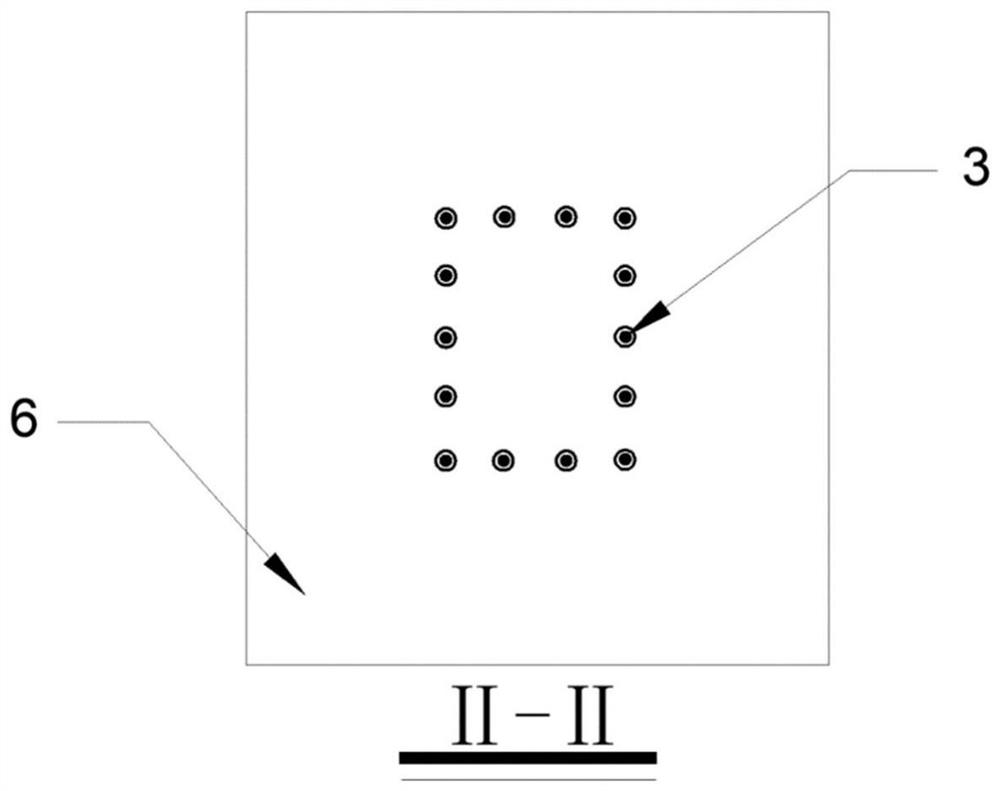

[0038] Part of the non-bonded grouting bellows prefabricated assembly connection structure in the present invention includes main reinforcement 1, metal bellows 3 and casing 2, see figure 1 . In this embodiment, by setting the unbonded section for the main reinforcement in the metal bellows, not only the ductility and energy dissipation capacity of the pier can be improved, but also the fatigue performance of the main reinforcement can be improved. At the same time, the construction process is simple, easy to operate, economical, and easy to popularize and apply.

[0039] One end of the main reinforcement 1 is anchored in the cap or cover beam. The metal bellows 3 is pre-embedded in the bearing platform or the cover beam, and the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com