Impact-resistant split type hydraulic lifting dam capable of preventing turbulence

A hydraulic lifting dam, impact resistance technology, applied in sustainable biological treatment, water/sludge/sewage treatment, marine engineering, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

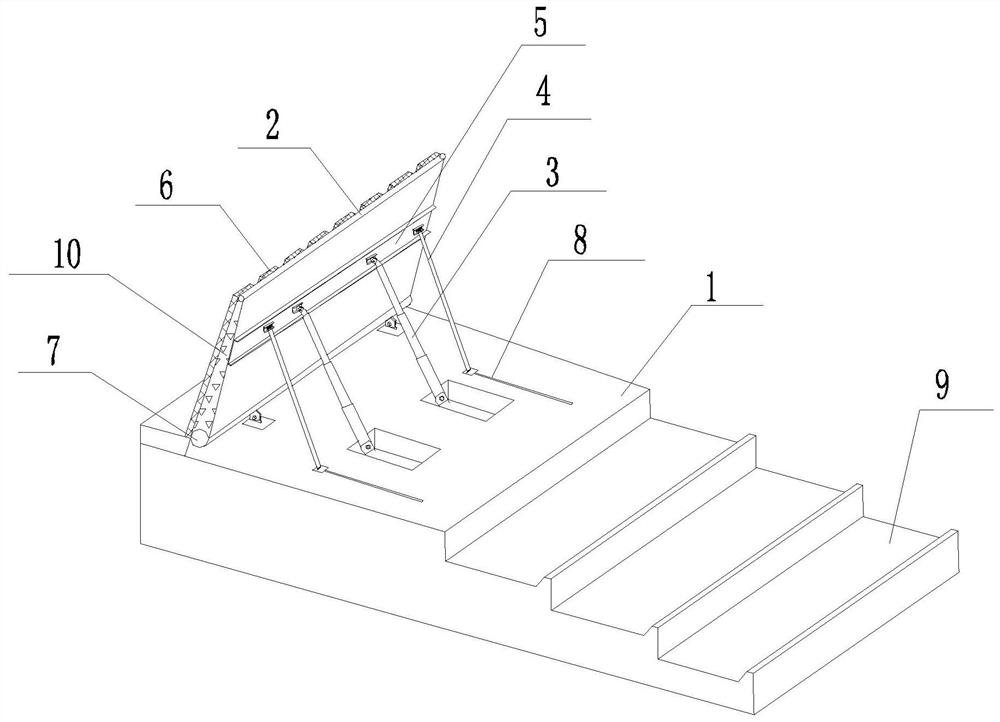

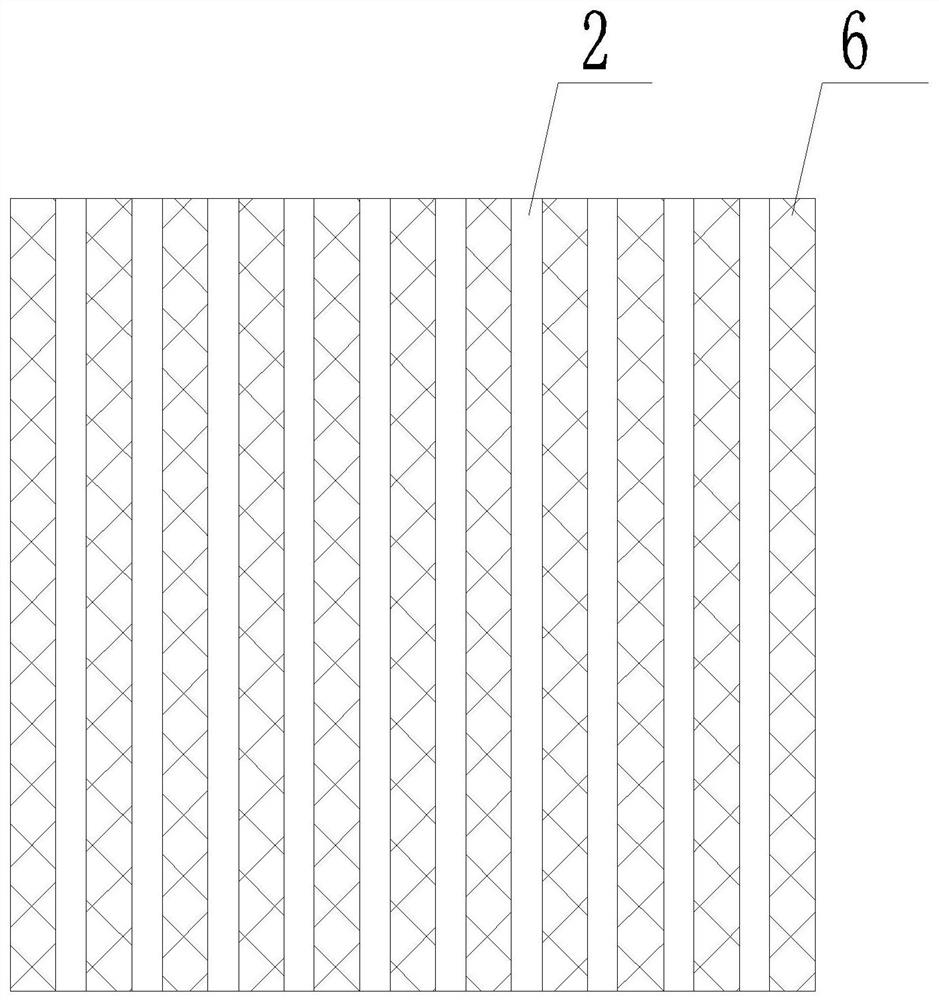

[0034] see figure 1 As shown, the anti-shock split hydraulic lifting dam provided in this embodiment can prevent turbulent flow, including dam body foundation 21, water retaining panel, hydraulic rod 3, drop water energy dissipation system 9, and the water retaining panel connects with the hinge 7 The dam body foundation 21 is connected, and a beam 5 is arranged on the water retaining panel. One end of the hydraulic rod 3 is connected to the beam 5, and the other end is connected to the embedded part of the dam surface. The driving hydraulic rod is set on the dam body foundation 21 on the back of the water retaining panel 3. Lifting oil cylinders are used to adjust the height of the dam surface. The hydraulic lifting dam is composed of multiple split water retaining panels; the dam body foundation 21 is provided with a reserved groove 8 for oil pipelines. When the dam body is in normal operation, a 30cm high water head is allowed to overflow on the dam to form a waterfall land...

Embodiment 2

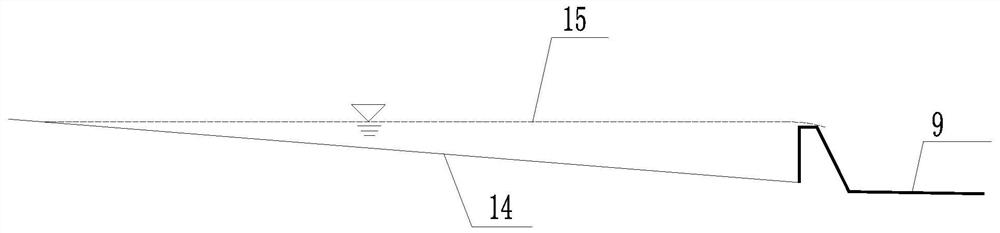

[0040] In this embodiment, on the basis of the structure of Embodiment 1, the falling water energy dissipation system 9 is further limited, and its structure is the same as that of Embodiment 1, so it will not be repeated in this embodiment.

[0041] attached Figure 4 The positions of relevant parameters are illustrated, and the hydraulic calculation method of the multi-level drop in this embodiment is as follows:

[0042] (1) The parameters of the first-stage drop 12 of the drop water energy dissipation system 9 are determined according to the following formula:

[0043]

[0044]

[0045]

[0046]

[0047] δ c1 =(1~2)H 1 (5)

[0048] In the formula, c 1 is the height of the first-level tail sill, in m; H 10 is the water head at the top of the first-level tail sill, in m; H 1 is the water depth at the top of the first-level tail sill, in m; l 1 is the length of the first-level platform, in m; δ c1 It is the length of the top of the first level tail sill, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com