Large-span steel structure roof transformation method

A steel structure and long-span technology, applied in building structure, building maintenance, construction, etc., can solve the problems of not meeting energy saving, environmental protection, comfort and aesthetics, increasing roof load, complex construction technology, etc., to solve roof seepage Leakage problem, reduce the roof structure load, the effect of structural safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

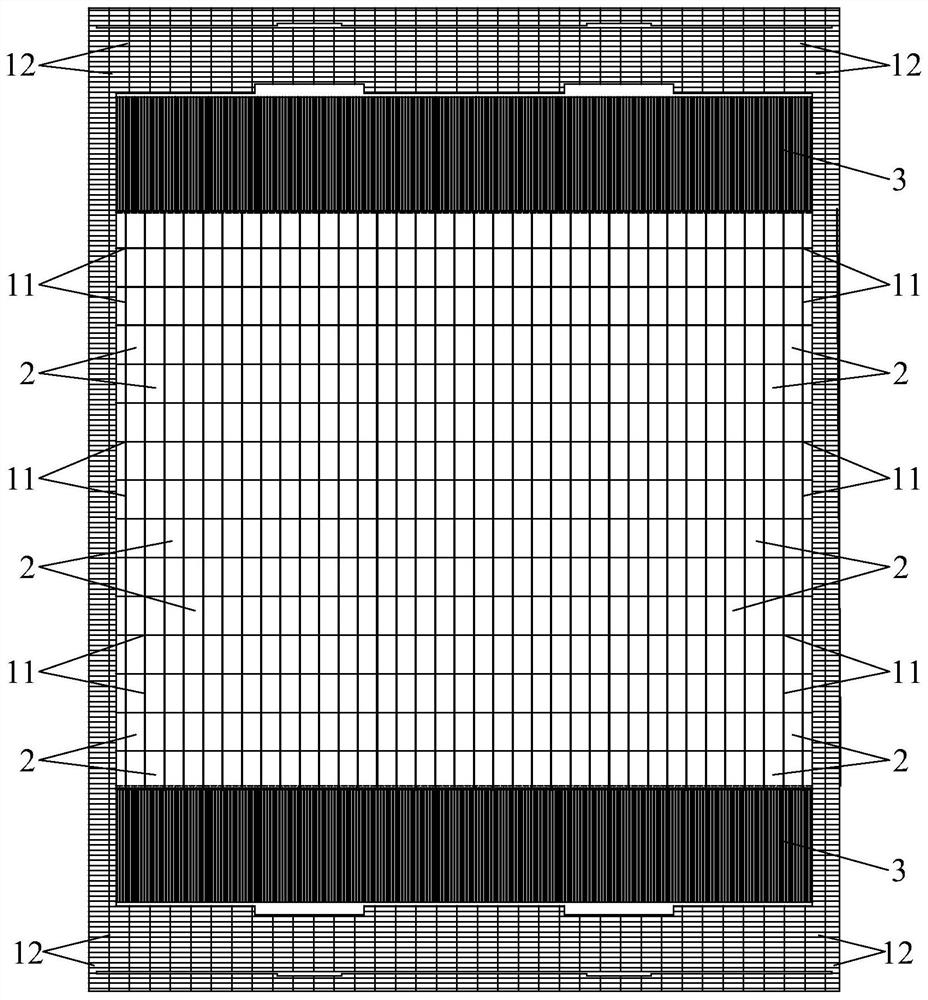

[0016] see figure 1 and figure 2 , the long-span steel structure roof renovation method of the present invention is used to transform the original roof of the long-span steel structure, comprising the following steps:

[0017] S11, removing the first roof panel located in the middle of the original roof, retaining the second roof panel 12 located at the edge of the original roof and the third roof panel 13 located between the first roof panel and the second roof panel 12 , the lower part of the first roof panel is covered with safety nets and fireproof tarpaulins to ensure construction safety;

[0018] S12, setting the ETFE air pillow film 2 on the first steel structure 11 corresponding to the original position of the first roof panel;

[0019] S13, add an aluminum-magnesium-manganese metal roof panel 3 covering the third roof panel 13 in the area between the ETFE air pillow membrane 2 and the second roof panel 12 .

Embodiment 2

[0021] see figure 1 and figure 2 , the long-span steel structure roof renovation method of the present invention is used to transform the original roof of the long-span steel structure, comprising the following steps:

[0022] S21, removing the first roof panel located in the middle of the original roof, retaining the second roof panel 12 located at the edge of the original roof and the third roof panel 13 located between the first roof panel and the second roof panel 12 , the lower part of the first roof panel is covered with safety nets and fireproof tarpaulins to ensure construction safety;

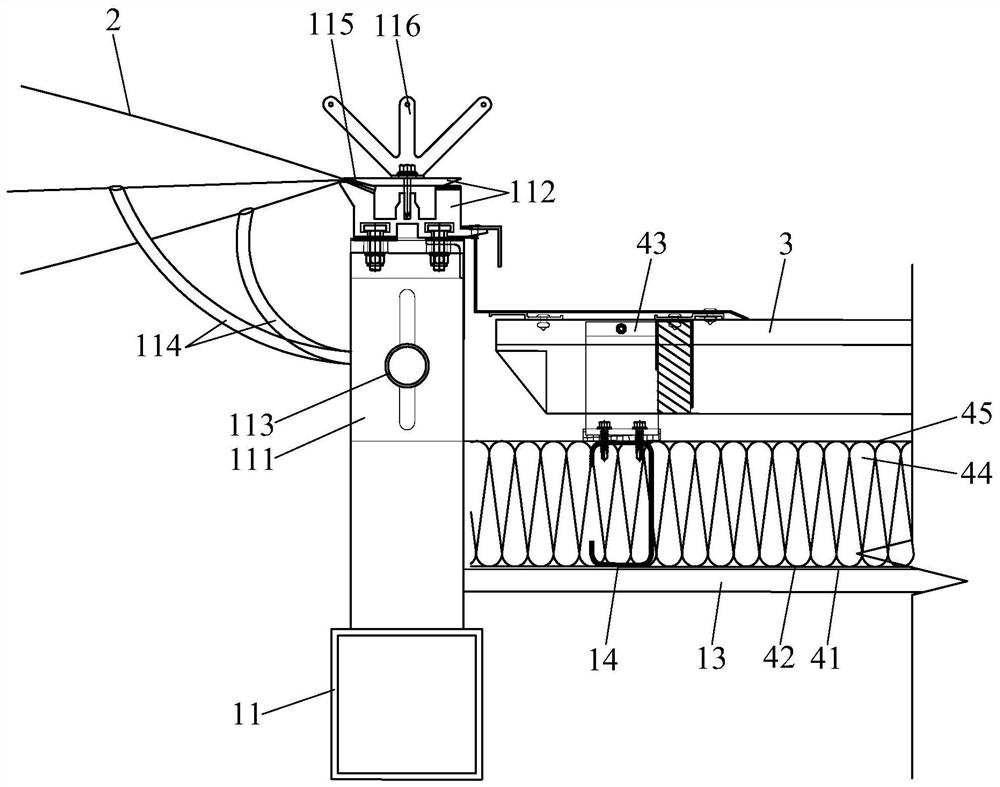

[0023] S22, provide ETFE air pillow membrane 2; arrange and install lightning protection grounding underground pipelines on the first steel structure 11; install secondary steel structure 111 on the first steel structure 11; install drainage sky on the secondary steel structure 111 The ditch 112 and the drainage gutter 112 are provided with an air pillow film connection position for...

Embodiment 3

[0026] see figure 1 and figure 2 , the long-span steel structure roof renovation method of the present invention is used to transform the original roof of the long-span steel structure, comprising the following steps:

[0027] S31, removing the first roof panel located in the middle of the original roof, retaining the second roof panel 12 located at the edge of the original roof and the third roof panel 13 located between the first roof panel and the second roof panel 12 , the lower part of the first roof panel is covered with safety nets and fireproof tarpaulins to ensure construction safety;

[0028] S32, provide ETFE air pillow membrane 2, confirm the position of the first steel structure 11, and recheck its size with the size of ETFE air pillow membrane 2; arrange and install lightning protection grounding underground pipelines on the first steel structure 11 ; Secondary steel structure 111 is installed on the first steel structure 11; Drainage gutter 112 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com