Short-radius controllable trajectory drilling tool

A drilling tool and short-radius technology, which is applied in the field of short-radius controllable trajectory drilling tools, can solve problems such as poor economic benefits, large borehole curvature, and increased difficulty in the construction of well sections, achieving short build-up rates and increased steering stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

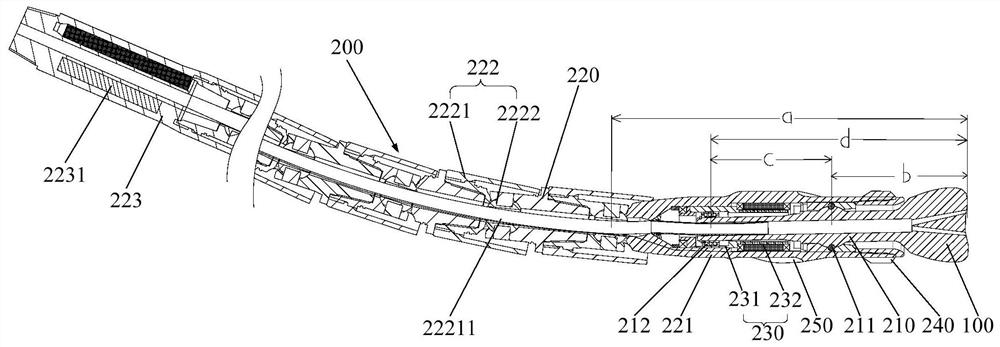

[0072] Such as figure 1 As shown, the offset lever 210 is inserted inside the carrying body 221, the deflection guide mechanism 230 includes an eccentric ring 231, and the carrying body 221 is provided with an electrical actuator 2211, the electrical actuator 2211 is a driving motor 232, and the driving motor 232 ring Set on the outside of the bias lever 210, the eccentric ring 231 is arranged on the top of the drive motor 232 and connected to the rotor output end of the drive motor 232, the drive motor 232 can drive the eccentric ring 231 to rotate, and the eccentric ring 231 and the bias lever 210 are arranged There is a bearing 212, and the rotation of the eccentric ring 231 can drive the bias lever 210 to swing around the controllable weight-on-bit torque deflection transmission mechanism 211 and / or rotate around the axis of the bearing body 221. Specifically, the eccentric ring 231 drives the bias lever 210 The direction of rotation of the rear end of the rear end around ...

Embodiment approach 2

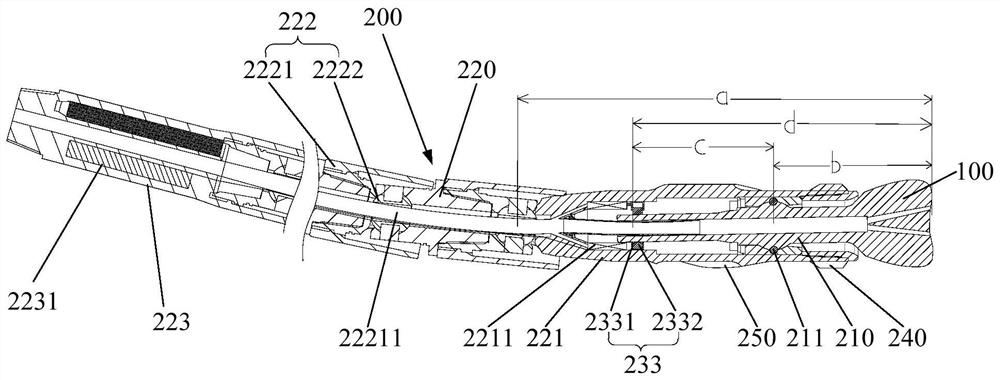

[0075] Such as figure 2 As shown, the bias lever 210 is inserted inside the carrying body 221, and the carrying body 221 is provided with an electrical actuator 2211, the electric actuator 2211 includes a solenoid valve 22111, and the deflection guide mechanism 230 includes at least three groups along the carrying body 221. The driving hydraulic cylinder 233 arranged radially at intervals, the driving hydraulic cylinder 233 includes a cylinder barrel 2331 connected to the side wall of the bearing body 221 and a driving piston 2332 arranged in the cylinder barrel 2331, the driving piston 2332 is connected with a pusher, and the electromagnetic The valve 22111 can periodically drive the driving piston 2332 to move along the radial direction of the bearing body 221, and the driving piston 2332 can periodically drive the pusher to move along the radial direction of the bearing body 221, and the movement of the pusher can drive the bias lever 210 Rotate around the center of the co...

Embodiment approach 3

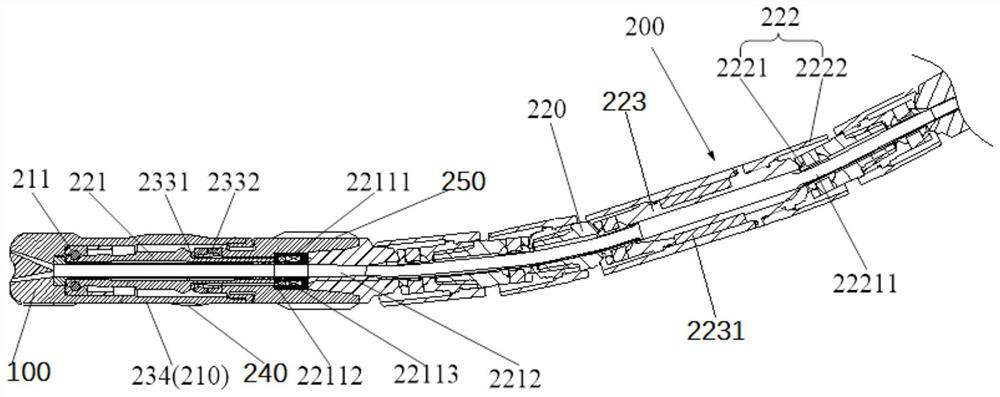

[0078] Such as image 3 and Figure 4 As shown, the bias lever 210 is a hinged sleeve 234, and the deflection guide mechanism 230 is connected to the inner wall surface of the bearing body 221. The deflection guide mechanism 230 includes at least three groups of driving hydraulic cylinders 233 arranged at intervals along the radial direction of the bearing body 221, The driving hydraulic cylinder 233 includes a cylinder 2331 connected to the side wall of the bearing body 221 and a driving piston 2332 arranged in the cylinder 2331. The driving piston 2332 can abut against the inner wall of the hinged sleeve 234, and the bearing body 221 also An electrical actuator 2211 is provided, and a flow channel 2212 is provided inside the carrying body 221. The electrical actuator 2211 includes a plurality of solenoid valves 22111 corresponding to each driving hydraulic cylinder 233. The solenoid valve 22111 has a first passage 22112 and a second passage 22113, the first passage 22112 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com