NOx gas sensor

A gas sensor and support layer technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of poor accuracy of semiconductor NOx gas sensors, difficult to meet the use environment, and lack of cheap operation, etc., to achieve stable and easy control of the processing technology , low power consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

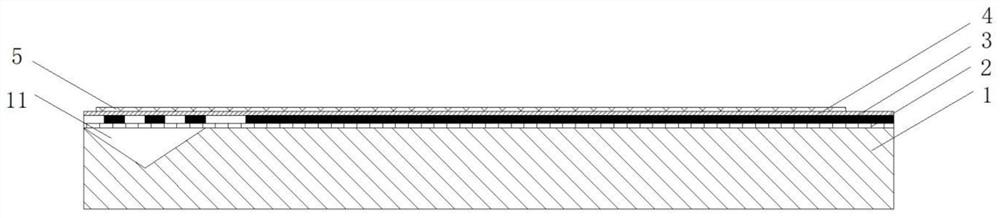

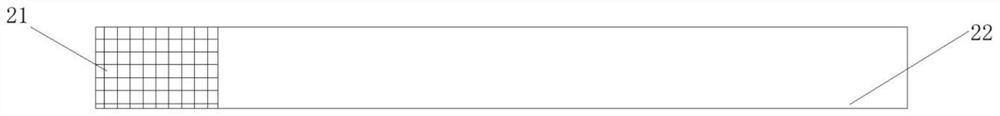

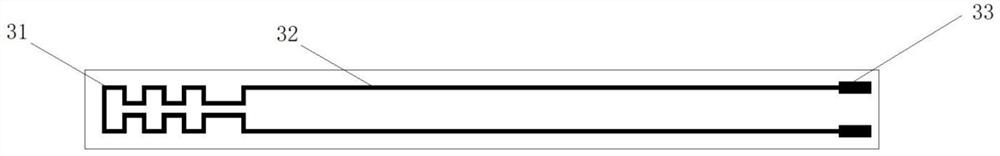

[0028] Such as Figure 1 to Figure 5 The shown embodiment of the present invention, the structure includes from bottom to top: a silicon base layer 1, a support layer 2, a heating electrode 3, an insulating layer 4, and a test electrode layer 5; wherein the silicon base layer 1 is a strip-shaped rectangular body, There is a thermal insulation cavity 11 on the side of the test end above the silicon base layer 1; the supporting layer 2 completely covers the silicon base layer 1; the heating electrode 3 is arranged between the supporting layer 2 and the insulating layer 4, and the insulating layer 4 is used to isolate the heating electrode 3 and the test electrode layer 5;

[0029] The test electrode layer 5 arranged on the insulating layer 4 includes: a second electrode 52, a first electrode 51 and a third electrode 53 arranged in parallel, wherein the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com