Multistage variable-vibration rock debris cleaning and screening device

A technology of cuttings and screens, which is applied in the field of multi-stage variable vibration cuttings cleaning and filtering devices, can solve the problems of unfavorable high-efficiency application of clean water resources, unfavorable conversion of new and old kinetic energy, high operating costs of equipment, etc., to achieve the variability of the screen surface and its Strong dynamic adjustability, beneficial to the conversion of new and old kinetic energy, and low equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

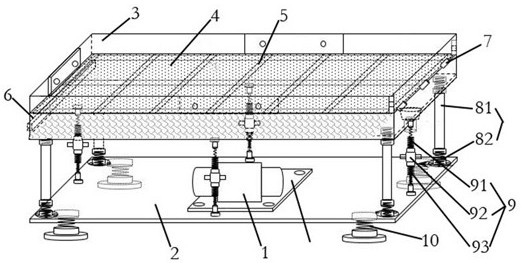

[0029] see figure 1 The shown multi-stage variable vibration cuttings cleaning and screening device includes a rectangular water tank 3 with an open top, a screen 4, a vibrating motor 1, and a rectangular vibrating plate 2.

[0030] The vibrating motor 1 is fixed on the top of the vibrating plate 2 by bolts, and the vibration damping support 10 is fixedly arranged under the four corners of the vibrating plate 2. A vibrating strut 8 is provided, and the vibrating strut 8 is connected with an elastic leg, which is fixedly connected with the vibrating plate 2, and the elastic leg includes a vibrating spring 82 or a rubber column.

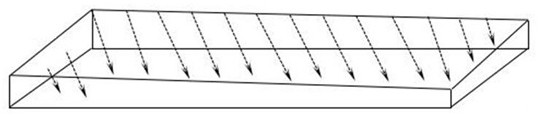

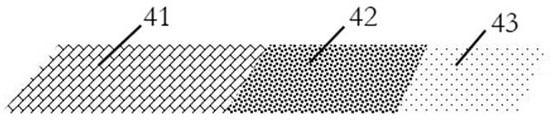

[0031] Between the screen 4 and the bottom of the water tank 3, there are also some supporting ribs 5 arranged along the length direction of the water tank 3. The screen 4 is placed on the supporting ribs 5, and the height of the supporting ribs 5 is along the length of the water tank 3. The direction decreases successively or along the diagonal direc...

Embodiment 2

[0037] A multi-stage variable vibration cuttings cleaning and filtering device includes a vibration excitation device and a screening and washing device, and the whole is made of stainless steel.

[0038] The vibration excitation device includes a vibration damping support 10 , a vibration plate 2 , a vibration motor 1 , a vibration strut 8 , and a variable vibration column 9 .

[0039] The screening and washing device includes a water tank 3 and a screen cloth 4 .

[0040] The vibrating plate 2 is the body that transmits the vibration. The vibrating plate 2 is a stainless steel plate with a length of 1000mm x a width of 500mm x a thickness of 6mm. The vibration transmission parts are installed on the vibrating plate 2: ① vibrating motor 1. The vibration motor 1 is an exciting motor, which is installed on the motor base, and the motor base is placed at the center of the vibration plate 2, and fixed by screws and the vibration plate 2; ② Vibration strut 8. It is arranged betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com