Multifunctional air treatment unit

An air treatment unit and multi-functional technology, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reducing installation space, achieve the effects of enhancing reliability, reducing layout space, and preventing pipeline corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

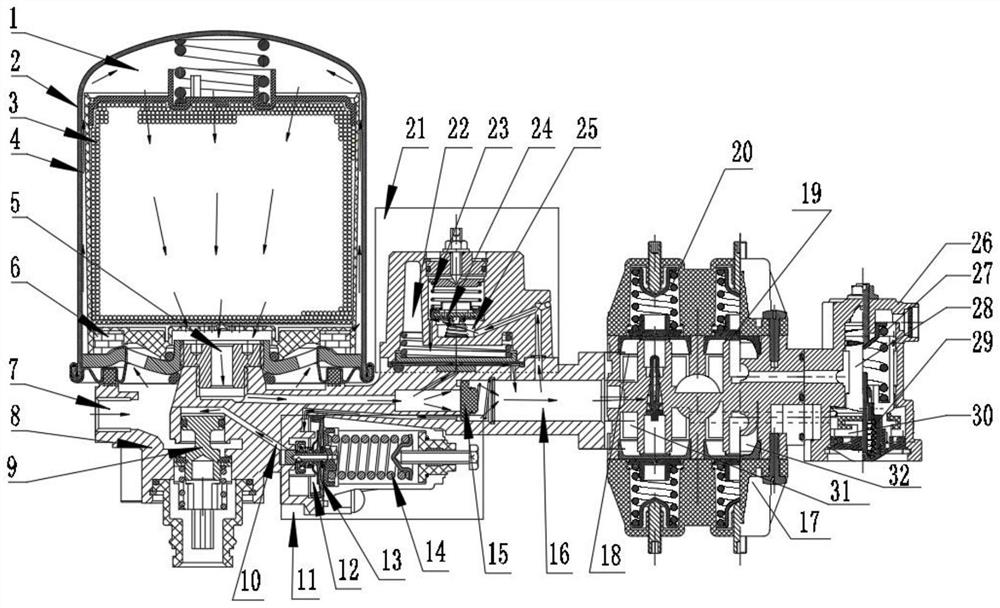

[0023] as attached figure 1 To attach figure 2 Shown:

[0024] The present invention provides a multi-functional air processing unit, comprising a dryer upper chamber 1, an air intake channel 7, an exhaust valve 9, a one-way valve 15, a pressure limiting valve 26; a dryer upper chamber 1, a drying cylinder assembly 2, Desiccant 3, annular channel 4, central channel 5, and filter 6 together form the air dryer assembly. The lower part of the air dryer assembly is provided with an air intake channel 7 for compressed air to enter. The filter 6 can effectively prevent impurities from The air leakage and failure of the dryer caused by impurities are avoided. The exhaust valve 9, unloading valve 11, backflow stop valve 21, and four-circuit protection valve 17 are all integrated on the same dryer body 8. The exhaust valve 9 and The unloading valves 11 are connected through the A chamber 10, the one-way valve 15 is installed at the inlet end of the C chamber 16, and the outlet end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com