A stainless steel u-shaped rib butt welding method with drainage function

A welding method, stainless steel technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve the effect of easy operation, qualified weld appearance and internal quality, and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

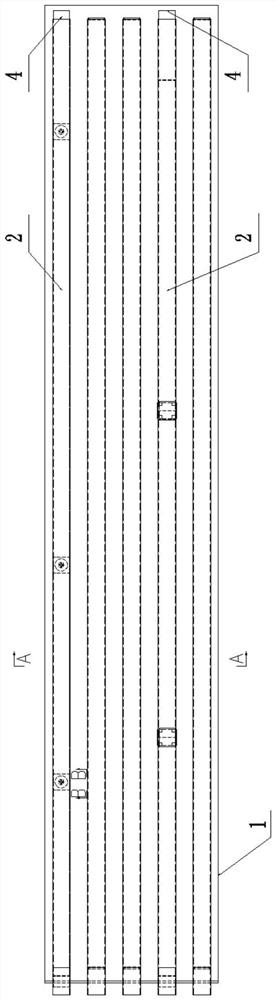

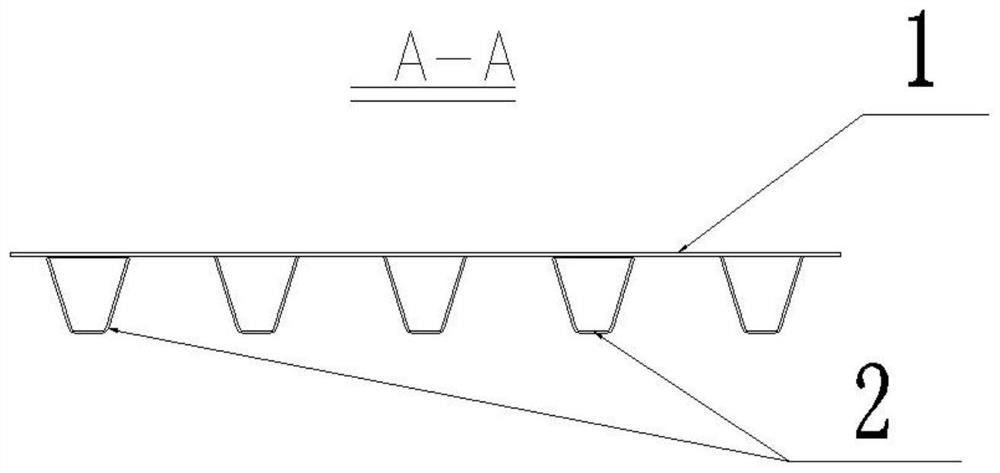

[0038] In order to ensure that the butt welding gap is within the allowable range, a certain length (such as 30cm) of stainless steel sheet inserts 6 is set between the bridge decks 1 of adjacent beam sections, and a certain length (such as 50cm) is set between the stainless steel U-shaped ribs 2. ) of the stainless steel U-rib insert section 5, refer to Figure 4 . The actual length of the stainless steel U-shaped rib embedded section is set according to the actual measurement data after the completion of the on-site beam section assembly and welding, and the principle is to ensure the gap of the butt weld. The machining of the stainless steel U-shaped rib inserting section should be finished by machine tool, and the accuracy of the blunt edge and the size of the opening should be strictly guaranteed, thereby ensuring the welding quality.

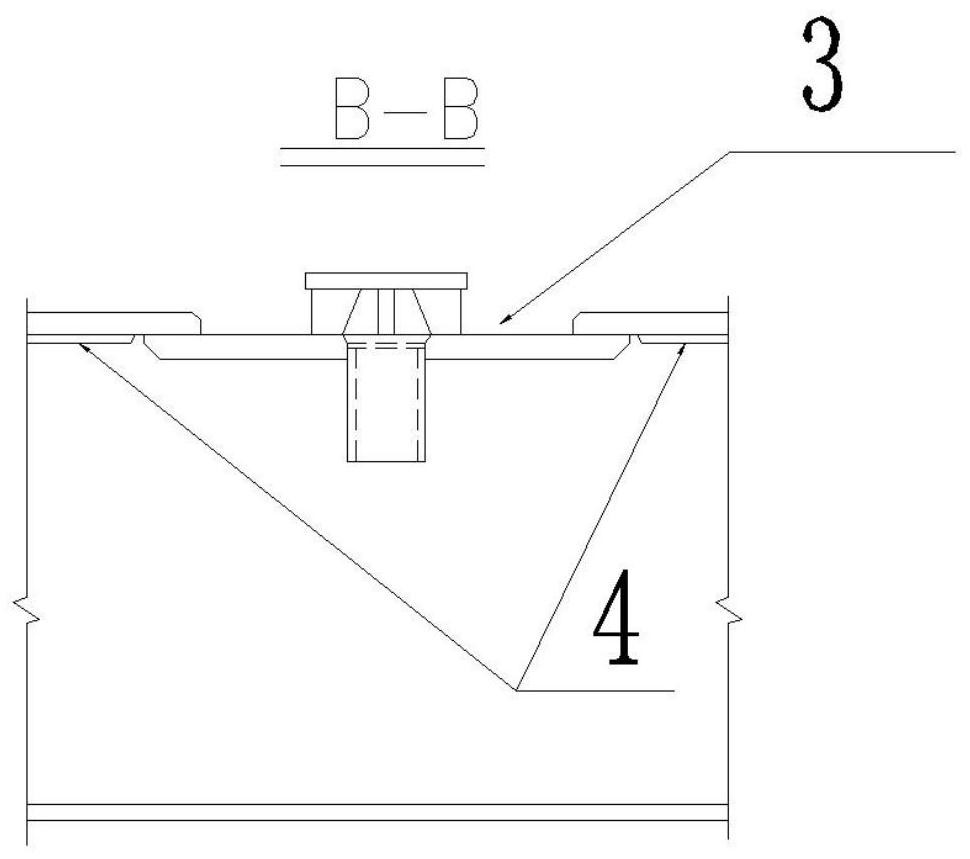

[0039]The back of the weld needs to be filled with inert gas for protection to prevent the weld metal from oxidizing, and the drainage s...

Embodiment 2

[0045] Based on the stainless steel U-rib butt welding method of Example 1, such as Figure 6-7 , including the following steps:

[0046] 1. Assemble and weld the 5mm thick stainless steel sheet insert section, the welding adopts the oxygen gas shielded welding, the overhead welding, the welding material is E309LT1-1 flux-cored wire, the diameter is 1.2mm, the welding current is 160-180A, and the welding voltage is 26-28V , the gas flow is 15-20L / min.

[0047] 2. 100% PT flaw detection shall be carried out 24 hours after the welding of the stainless steel sheet inserting segment. After the flaw detection is qualified, the stainless steel U-shaped rib inserting segment shall be tested and the butt weld groove of the stainless steel U-shaped rib inserting segment shall be inspected. , the groove is required to be a bilateral V-shaped groove, the blunt edge is 0mm, the groove angle is 60±5°, and the gap is 3-5mm. Figure 8 , if it does not meet the requirements, it will be repa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com