Electric welding machine capable of automatically replacing welding electrodes

A technology of automatic replacement and welding electrodes, applied in welding accessories, grinding drive devices, grinding machine parts, etc., can solve the problems of operator sucking, affecting welding effect, unable to weld welds, etc., to accelerate the passage of current , The effect of shortening clamping time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

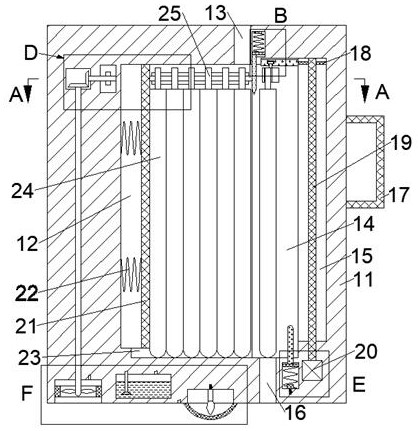

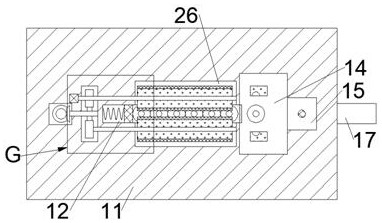

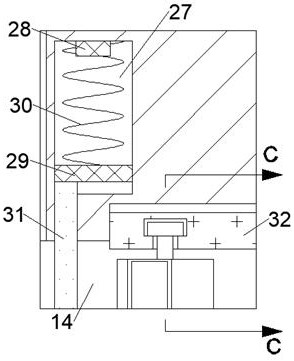

[0021] Combine below Figure 1-8 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0022] An electric welding machine capable of automatically replacing welding rods according to the present invention includes a body 11, a storage chamber 12 is provided inside the body 11, and the upper wall surface on the right side of the storage chamber 12 communicates with the upper end surface of the body 11 A feed hole 13 is provided, the right wall of the feed hole 13 is communicated with a clamping cavity 14 extending to the right, the right wall of the clamping cavity 14 is connected with a lift cavity 15 extending to the right, and the storage cavity 12 The lower wall is communicated with a guide chute 23 with an upward opening, and a feeding plate 21 capable of sliding le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com