Preparation method of aluminum alloy welding wire

A technology of aluminum alloy welding wire and preparation system, applied in welding equipment, metal processing equipment, welding medium, etc., can solve the problems of peeling off the coating, unable to protect the welding core, cracking of the coating, etc., to avoid different angles and positions, batch Fast processing efficiency, avoid cracking and peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

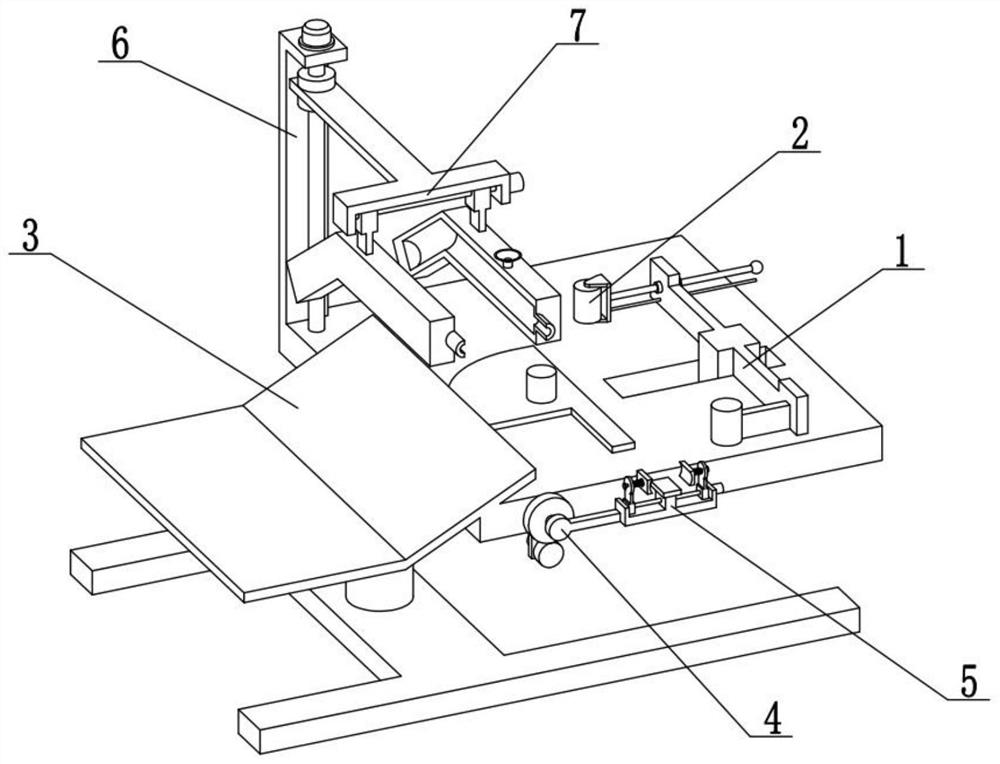

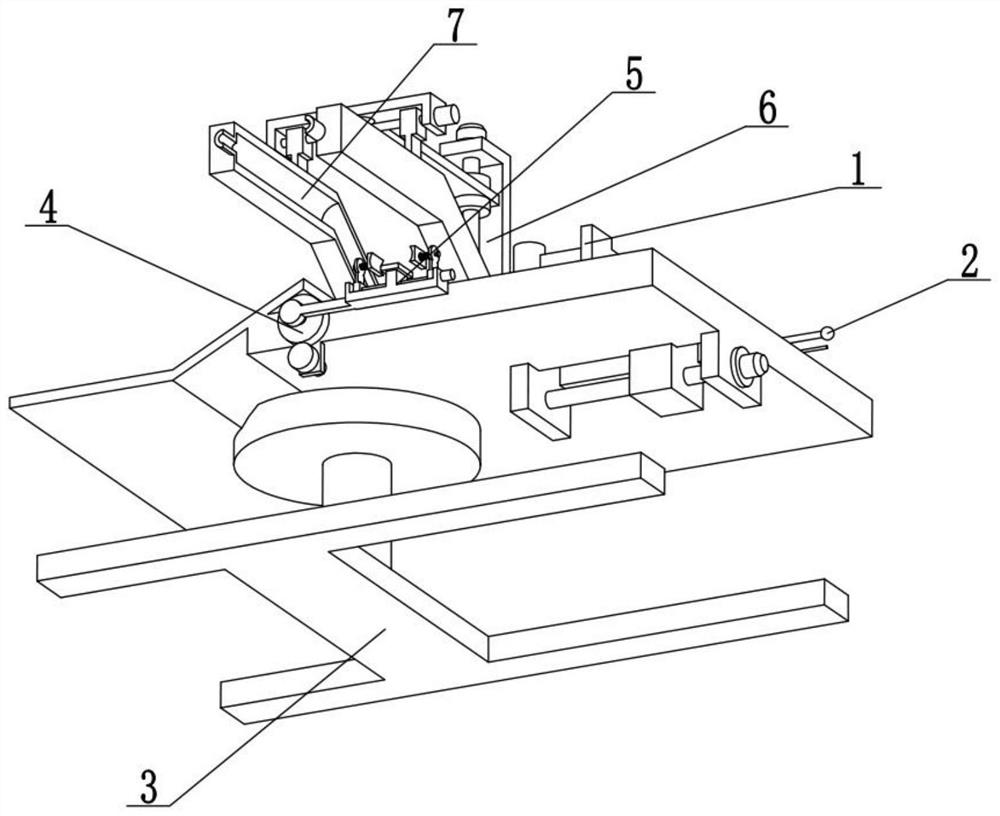

[0035] Combine below Figure 1-11 To illustrate this embodiment, a method for preparing an aluminum alloy welding wire includes the following steps:

[0036] Step 1: Fix the welding core of the aluminum alloy welding wire;

[0037] Step 2: Bending the welding core of the aluminum alloy welding wire;

[0038] Step 3: Turn the welding core of the bent aluminum alloy welding wire to the middle of the mold;

[0039] Step 4: Pouring the welding core of the bent aluminum alloy welding wire so that the welding core of the bent aluminum alloy welding wire is covered by the coating;

[0040] The above-mentioned preparation method of aluminum alloy welding wire also relates to an aluminum alloy welding wire preparation system;

[0041] The aluminum alloy welding wire preparation system includes a traverse compression mechanism 1, a bending and extrusion mechanism 2, a working platform mechanism 3, a position rotation mechanism 4, a welding core clamping mechanism 5, a height lifting ...

specific Embodiment approach 2

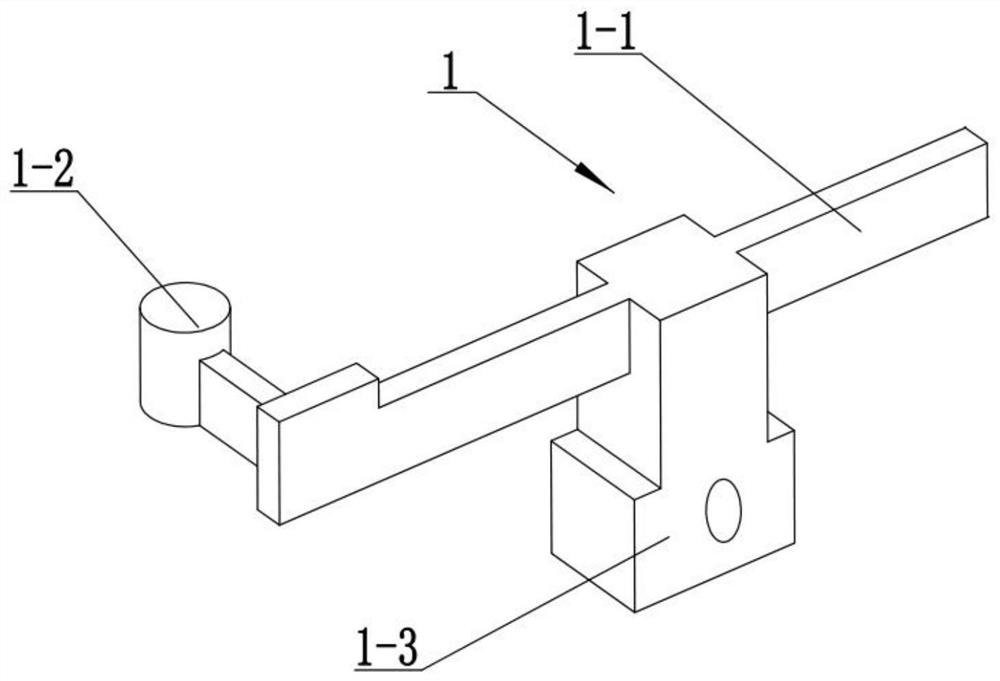

[0044] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the described traverse pressing mechanism 1 includes a beam 1-1, a limit column 1-2 and a sliding block 1-3, and the limit column 1-2 is fixed Connected on the crossbeam 1-1, the crossbeam 1-1 is fixedly connected on the sliding block 1-3.

specific Embodiment approach 3

[0046] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the second embodiment, the bending extrusion mechanism 2 includes a wall plate 2-1, a threaded pipe 2-2, a gear ring 2-3, and an extrusion screw rod 2- 4. Driving gear 2-5, driving motor 2-6, extrusion wheel 2-7 and limit rod 2-8, limit rod 2-8 is fixedly connected on the extrusion screw rod 2-4, limit rod 2 -8 is slidingly connected to the wall plate 2-1, the wall plate 2-1 is fixedly connected to the beam 1-1, the extrusion wheel 2-7 is rotatably connected to the extrusion screw rod 2-4, and the extrusion screw rod 2- 4. The upper thread is connected in the threaded pipe 2-2, the threaded pipe 2-2 is rotatably connected to the wall plate 2-1, the gear ring 2-3 is fixedly connected to the threaded pipe 2-2, the gear ring 2-3 is connected with the driving gear 2-5 meshing transmission, the driving gear 2-5 is fixedly connected to the output shaft of the driving motor 2-6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com