New material processing device

A processing device and new material technology, applied in the direction of grinding drive device, metal processing equipment, grinding/polishing safety device, etc., can solve the problems of reducing the applicability of use, affecting the processing accuracy, and adjusting the processing angle, so as to improve the use Practicality, improving the applicability of use, and ensuring the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

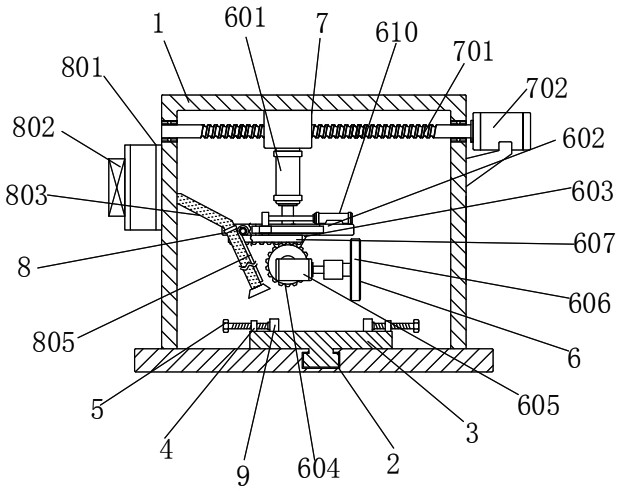

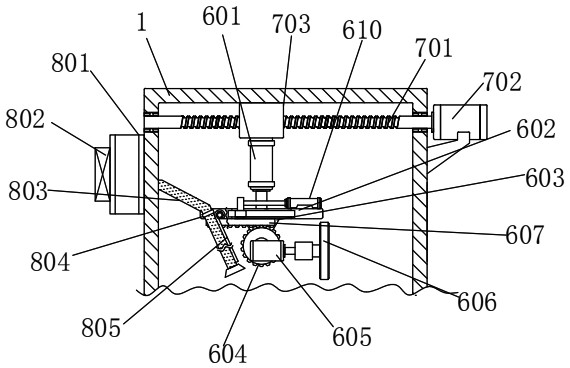

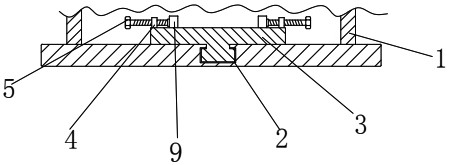

[0031] A new material processing device, including a body 1, the bottom of the inner wall of the body 1 is fitted with a supporting plate 3 through the gap of the chute 2, the chute 2 plays a guiding role for the supporting plate 3, and the left and right sides of the top of the supporting plate 3 are equipped with Two brackets 4, the bottom of the bracket 4 is fixedly connected with the left and right sides of the top of the supporting plate 3, the internal thread of the bracket 4 is connected with a bolt 5, and the inner end of the bolt 5 is provided with a clamping block 9, and the rotation of the bolt 5 drives the clamping block 9 horizontally Sliding, the bottom of the clamping block 9 fits with the top of the supporting plate 3, the outer end of the clamping block 9 is rotationally connected with the inner end of the bolt 5, and the inside of the body 1 is provided with a processing component 6;

[0032] The processing assembly 6 includes a first cylinder 601, a horizonta...

Embodiment 2

[0034] As an option, see figure 1 , 2 And 4, the new material processing device, the top of the first cylinder 601 is provided with a traversing assembly 7, the traversing assembly 7 includes a lead screw 701, a second motor 702 and a sliding seat 703, and the left and right ends of the lead screw 701 are respectively connected to the body 1 The left and right sides above the inner wall of the screw are connected by rotation. The right end of the lead screw 701 is provided with a second motor 702. The model of the second motor 702 is SM80-D601930. The bottom bracket of the second motor 702 is fixedly connected with the right end of the body 1. The output end of motor 702 is fixedly connected with the right end of leading screw 701, and the outer wall thread of leading screw 701 is connected with sliding seat 703, and sliding seat 703 can slide horizontally when leading screw 701 rotates, and the bottom of sliding seat 703 and the top of first cylinder 601 Fixedly connected, the...

Embodiment 3

[0037] As an option, see figure 1 , 2 , 5 and 6, a new material processing device, the left side of the body 1 is provided with a dust suction assembly 8, the dust suction assembly 8 includes a dust collection box 801, an exhaust fan 802, a hose 803, a snap ring 804 and a gooseneck 805, the collection The right end of the dust box 801 is fixedly connected to the left end of the body 1. The left end of the dust box 801 is provided with an exhaust fan 802. The model of the exhaust fan 802 is HG-HF-150P. At the left end, the right end of the dust collection box 801 is provided with a hose 803. The left end of the outer wall of the hose 803 runs through the left end of the inner wall of the body 1 and communicates with the right end of the dust collection box 801. The bottom of the hose 803 is fixed with a round cover. The outer wall gap of 803 is matched with snap ring 804, and snap ring 804 plays a role of guiding and limiting the flexible pipe 803, the rear end of snap ring 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com