Curved wood component cutting system and method

A cutting system and cutting method technology, applied in sawing equipment, wood processing appliances, manipulators, etc., can solve the problems of inability to process hyperbolic components, restricting the development of wooden structure buildings, and inability to meet processing technology, and improve cutting accuracy. and cutting efficiency, improve cutting efficiency, improve the effect of freedom of movement in space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

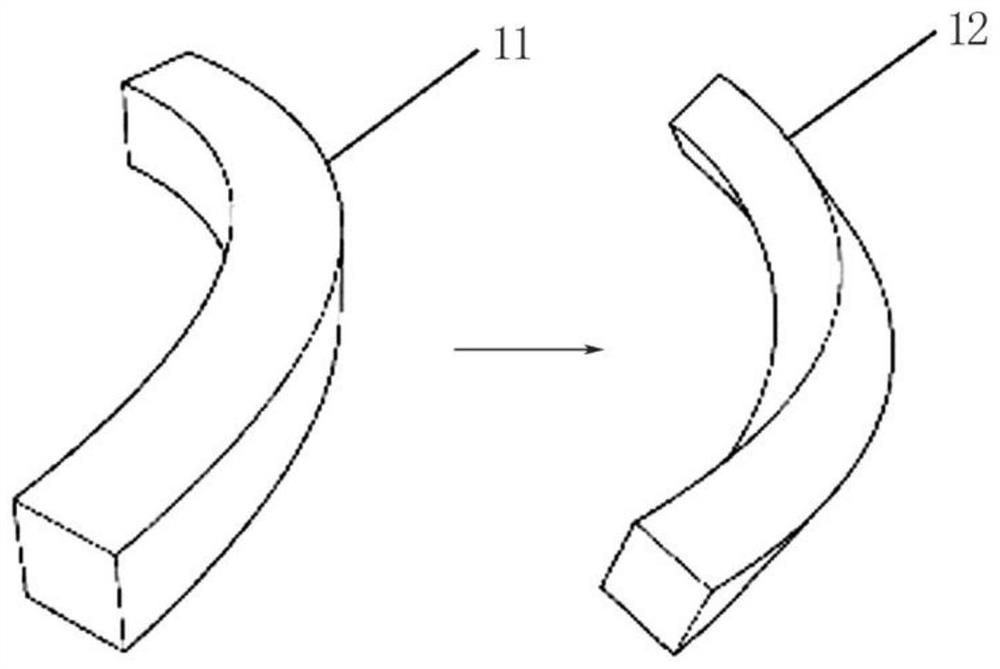

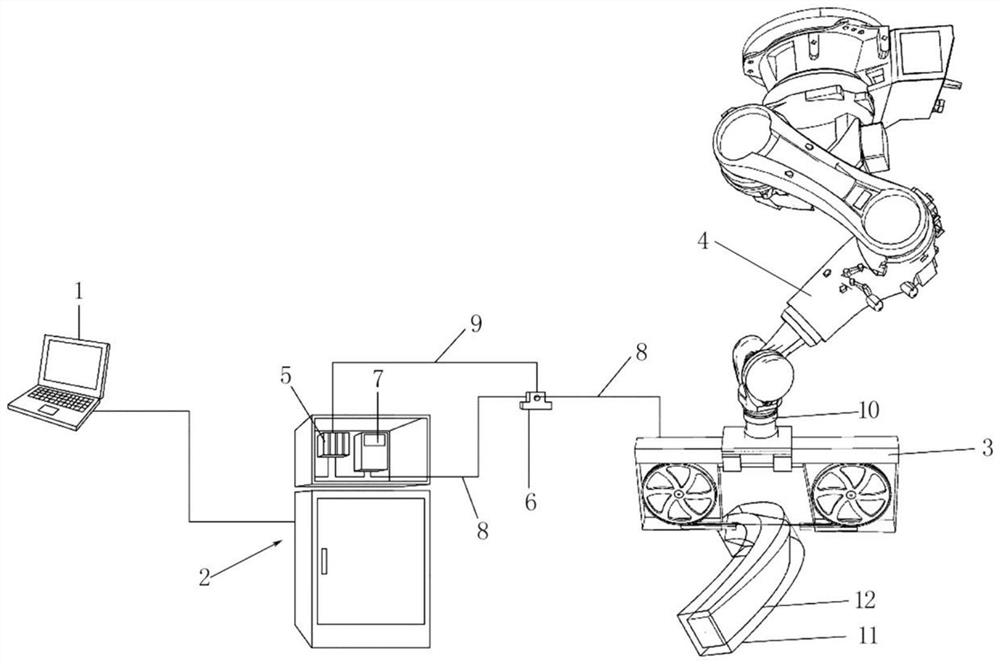

[0032]according tofigure 2A curvilinear component cutting system shown includes a computer 1, a control system 2, a cutting device 3, and a robot for driving the cutting device 3. The computer 1 includes three-dimensional modeling software, a modeling unit in the robot programming software, The shape-finding unit, the path planning unit and the programming unit; the modeling unit is used to construct the target curve component model; the shape-finding unit is used to find the shape of the minimum volume initial component material 11 that can wrap the target curve component 12 The path planning unit is used to obtain the cutting path of the target curve member 12 according to the morphological planning of the initial member material 11; the programming unit is used to write the cutting control program according to the cutting path;

[0033]The control system 2 includes a frequency converter 5, a current transformer 6 and a PLC 7, which is used to control the cutting speed of the cutting...

Embodiment 2

[0036]A method for cutting curved components, using the cutting system described in Embodiment 1, includes the following steps:

[0037]First establish the target curve component model on the computer 1 three-dimensional modeling software, and then use the genetic algorithm to find the smallest linear wood component or single curve wood component that can wrap the target component as the initial material component 11 in order to use mature wood gluing technology in production.

[0038]After the production of the initial material component 11 is completed, it is placed in the processing range of the robot, and the position of the initial material component 11 is determined by the robot, and then transmitted to the computer 1 for the design of the robot cutting path. In the robot programming software of the computer 1, according to the requirements of the target curve component 12, the ruled curved surface is extracted to generate the cutting path of the mechanical arm 13, and the cutting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com