High-precision automatic cutting machine for paper products and working method thereof

A cutting machine, high-precision technology, applied in thin material processing, sending objects, transportation and packaging, etc., can solve the problem of inconvenient operation of the cutting machine, little consideration of personalized design, low automation and intelligence. and other problems, to achieve the effect of high degree of automation, reasonable structure design, and improved production efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

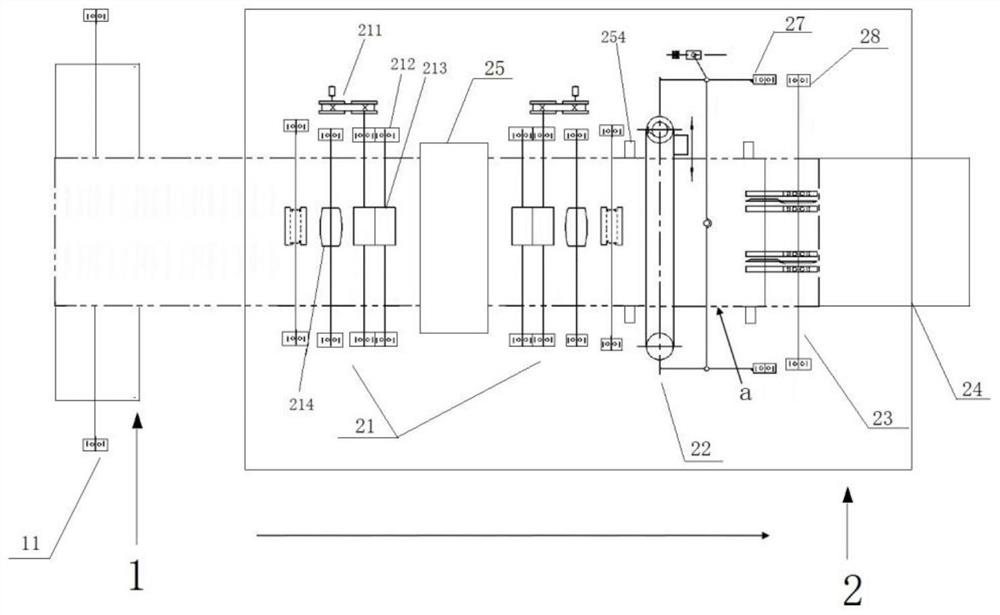

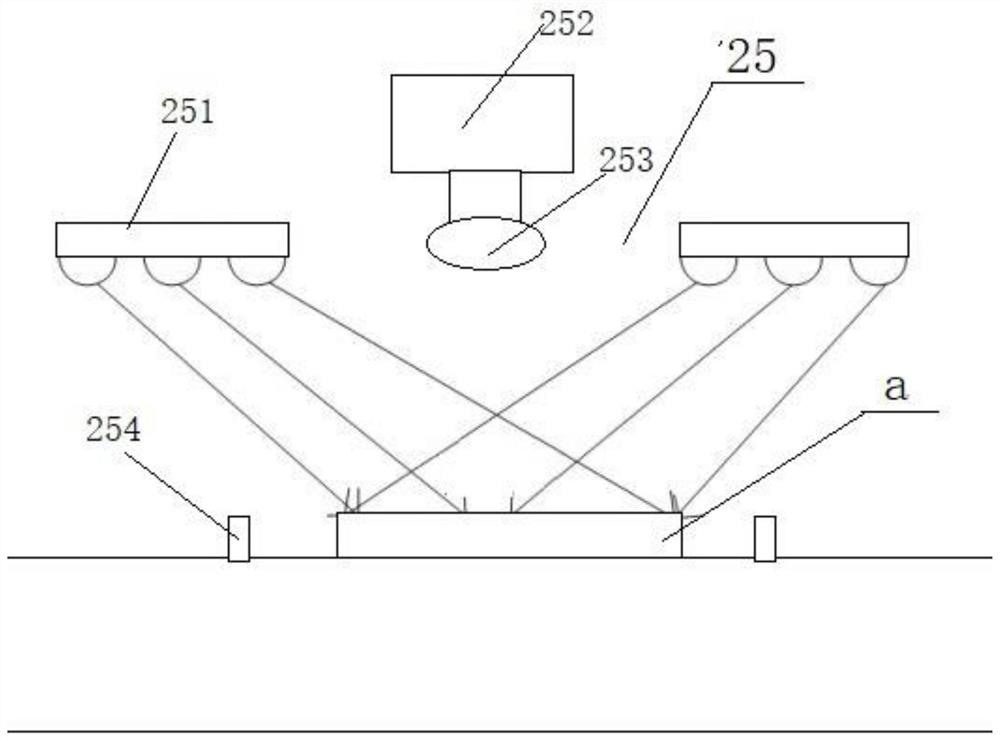

[0052] The high-precision automatic cutting machine for paper products according to the present invention comprises the following steps in turn:

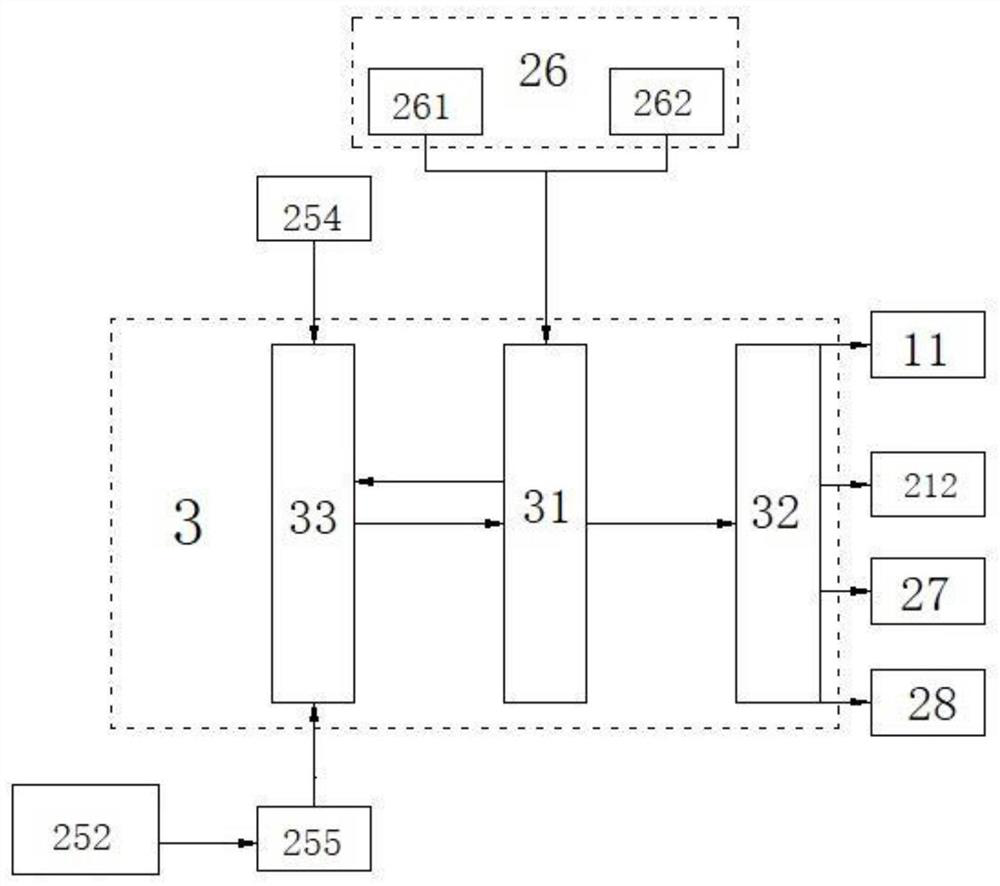

[0053] (1) Unwinding: Unwind the cut material through the independent unwinder 1. During unwinding, the tension detection module 26 detects the current tension information of the independent unwinder 1 and transmits it to the PLC controller 31, and the PLC controller 31 accepts The industrial computer 33 calculates the best operating state of the independent unwinder 1 and drives the unwinding servo motor 11 through the servo driver 32 to control the unwinding tension of the independent unwinder 1 about the information about the tension of the independent unwinder 1 and the operation command;

[0054] (2) Traction: The tension detection module 26 detects the current tension information of each pinch roller group 21 and transmits it to the PLC controller 31, and the PLC controller 31 receives the information about the tension of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com