Pressing and rotating mechanism for gasket in cosmetic bottle body

A technology of pressing and rotating, inner gasket, applied in the directions of bottle/container caps, closures, household utensils, etc. The effect of feeding and feeding, improving the pressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

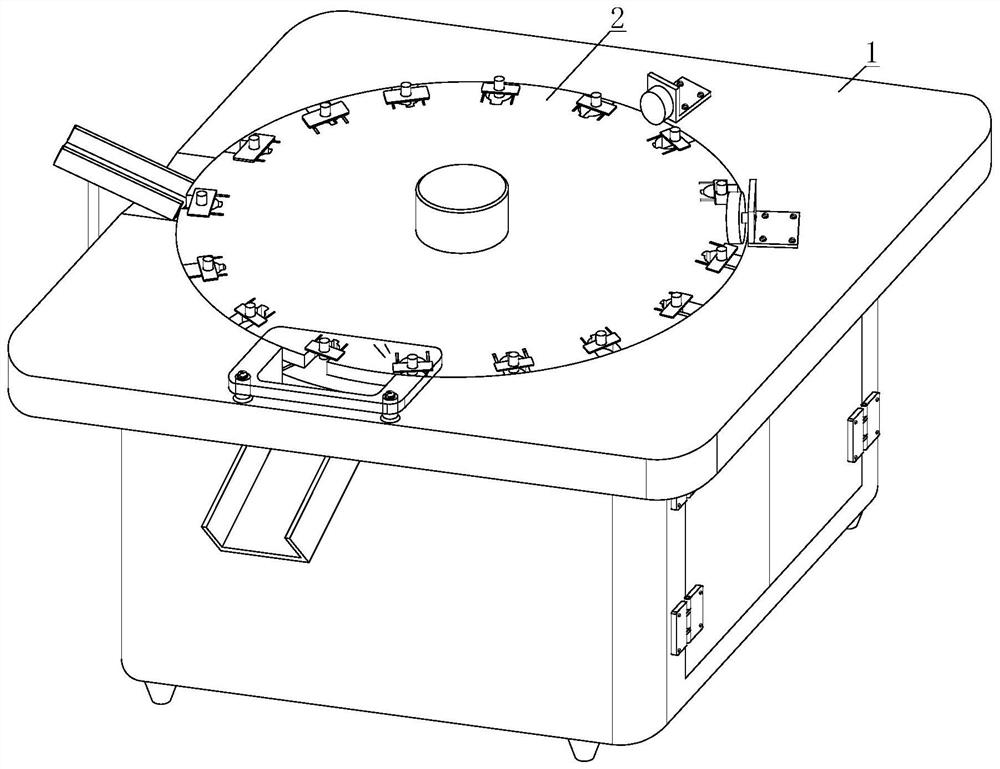

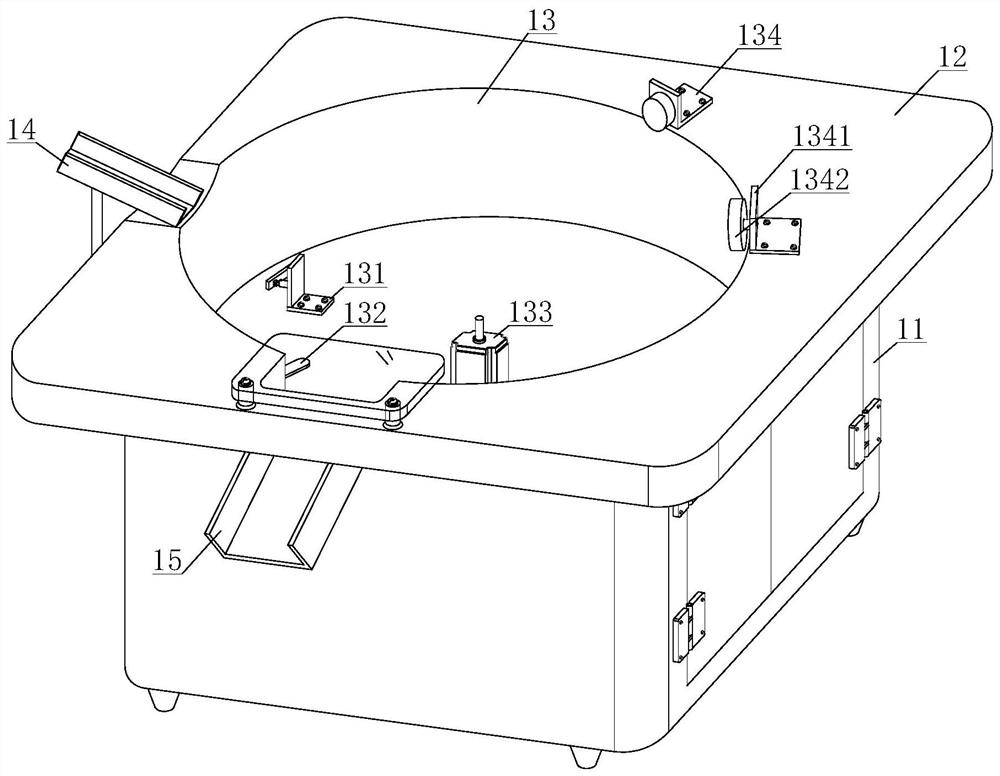

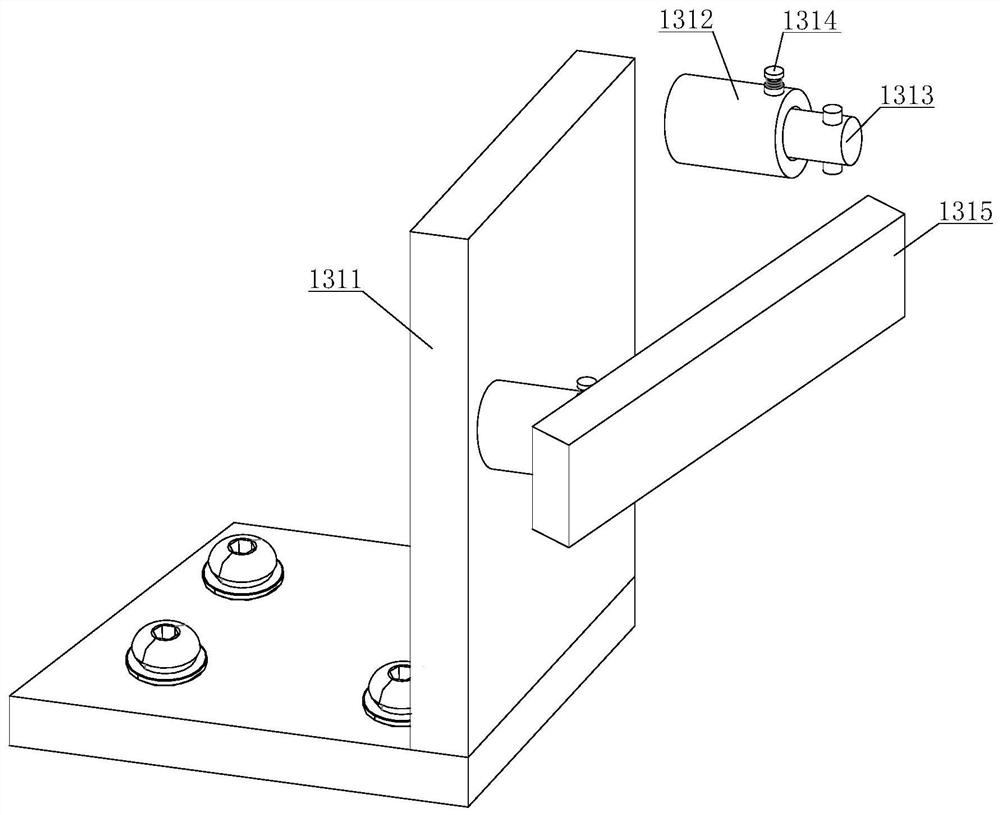

[0034] see Figure 1-2, a gasket pressing and rotating mechanism in a cosmetic bottle, including a pressing device 1 and a rotating device 2, the upper end of the pressing device 1 is equipped with a rotating device 2, and the pressing device 1 includes a main machine 11, a rotating table 12, and a rotating groove 13 , the rotary slot 13 includes a first connecting piece 131, a blanking plate 132, a servo motor 133 and a second connecting piece 134, the second connecting piece 134 includes a second support plate 1341 and a roller 1342, and one end of the second connecting piece 134 is installed sideways There is a second support plate 1341, a roller 1342 is installed on the side of one end of the second support plate 1341, a first connecting piece 131 is installed on the bottom surface of the inner cavity of the rotating groove 13, and a blanking plate 132 is installed on the inner cavity wall of the rotating groove 13, and The blanking plate 132 is positioned at one end side ...

Embodiment 2

[0040] see Figure 1-2 , a gasket pressing and rotating mechanism in a cosmetic bottle, including a pressing device 1 and a rotating device 2, the upper end of the pressing device 1 is equipped with a rotating device 2, and the pressing device 1 includes a main machine 11, a rotating table 12, and a rotating groove 13 , the rotary slot 13 includes a first connecting piece 131, a blanking plate 132, a servo motor 133 and a second connecting piece 134, the second connecting piece 134 includes a second support plate 1341 and a roller 1342, and one end of the second connecting piece 134 is installed sideways There is a second support plate 1341, a roller 1342 is installed on the side of one end of the second support plate 1341, a first connecting piece 131 is installed on the bottom surface of the inner cavity of the rotating groove 13, and a blanking plate 132 is installed on the inner cavity wall of the rotating groove 13, and The blanking plate 132 is positioned at one end side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap