Ophthalmic polymeric materials, making method, and use thereof

A kind of polymer material and polymer technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of whitening, low flash point, high water content, etc., to overcome the whitening phenomenon and high water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] The preparation of embodiment 1 polymer P1

[0091] Mix HEMA (5 g), DEOPOMA (31 g), PEA (42 g), PEMA (22 g), BDDA (2.5 g), EGDMA (2.5 g), Uv-01 (2 g), and P16 (0.05 g) well, then transfer Put it into a cavity mold made of glass or polypropylene or polytetrafluoroethylene (cavity diameter 15mm, height 15cm), and then put it in an oven at 100±2°C for 24 hours to obtain a transparent and elastic polymer. The resulting polymer is removed by Soxhlet extraction with ethanol to remove residual monomers or oligomers, and then dried in vacuum at 60°C±2°C for 24 hours, and then the material is processed into specifications with a central thickness of 0.7mm, an edge thickness of 0.30mm, and a diameter of Intraocular lens with a diameter of 6mm and a radius of curvature of 18mm.

Embodiment 2-5

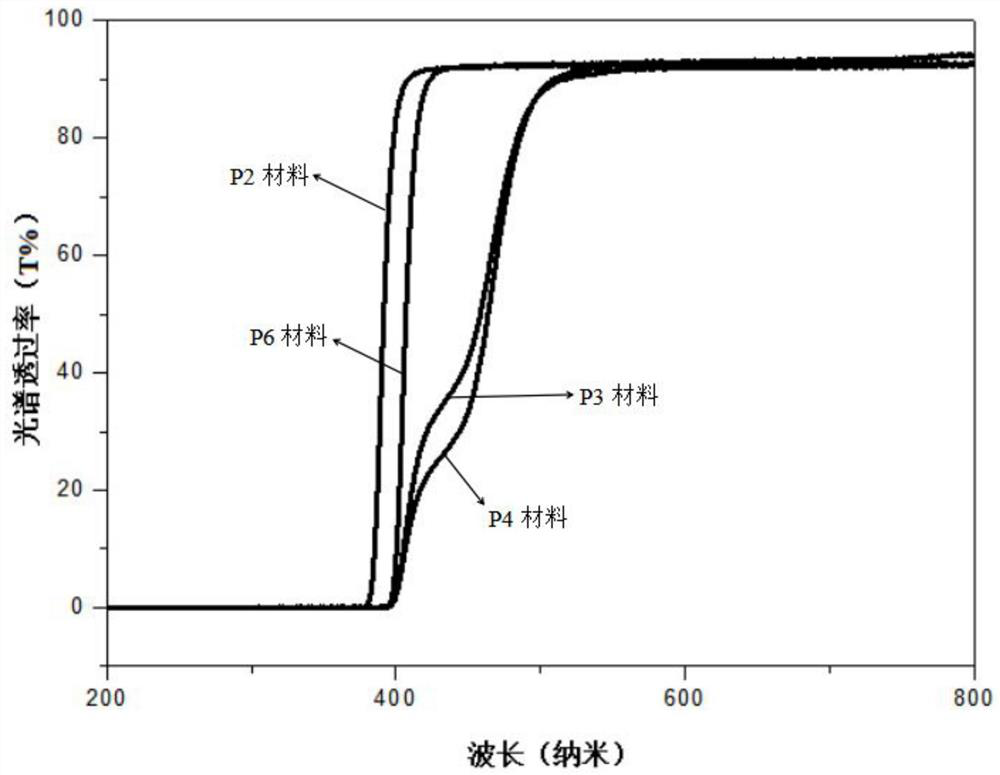

[0092] The preparation of embodiment 2-5 polymer P2, P3, P4, P5 and P6

[0093] The preparation method of polymers P2, P3, P4 and P6 is the same as that of P1, and the quality composition of each formula is shown in Table 1.

Embodiment 7

[0094] The preparation method of embodiment 7 polymer P7

[0095] MOHEMA(8g), MOHEA(2g), POHEA(2g), PEG1000MA(5g), EA(23g), PEA(60g), TMPTA(4g), Uv-02(1.5g), P16(0.05g), TPO (0.05g) and DMNMA (0.05g) are mixed evenly, and then the mixture is transferred to a cavity mold made of glass or polypropylene or Teflon (cavity diameter 15mm, height 15cm), and then a 4.8Kw high-pressure mercury lamp After irradiating for 2 minutes, put it into an oven at 100±2°C and keep it warm for 10 hours to obtain a transparent and elastic polymer. The resulting polymer was removed by Soxhlet extraction with ethanol to remove residual monomers or oligomers, then dried in vacuum at 60±2°C for 24 hours, and then the material was processed into specifications with a central thickness of 0.67mm, an edge thickness of 0.27mm, and a diameter of IOL lens with 6mm and 18mm radius of curvature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com