Multi-functional truss supporting type floor slab and construction method thereof

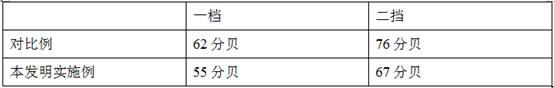

A supporting and multi-functional technology, applied in the direction of floors, heating methods, building components, etc., can solve the problems of energy saving and consumption reduction without much help, reduce indoor height, consume threaded steel, etc., and achieve excellent sound and heat insulation effects, The effect of reducing energy consumption and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

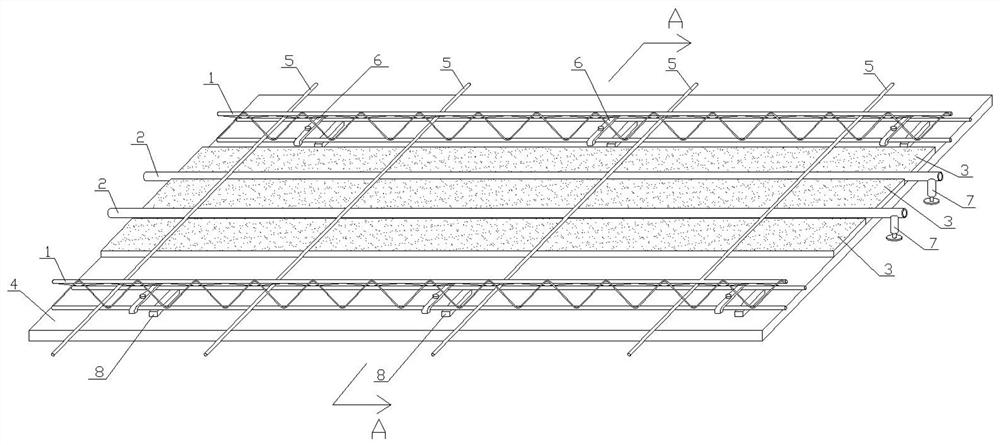

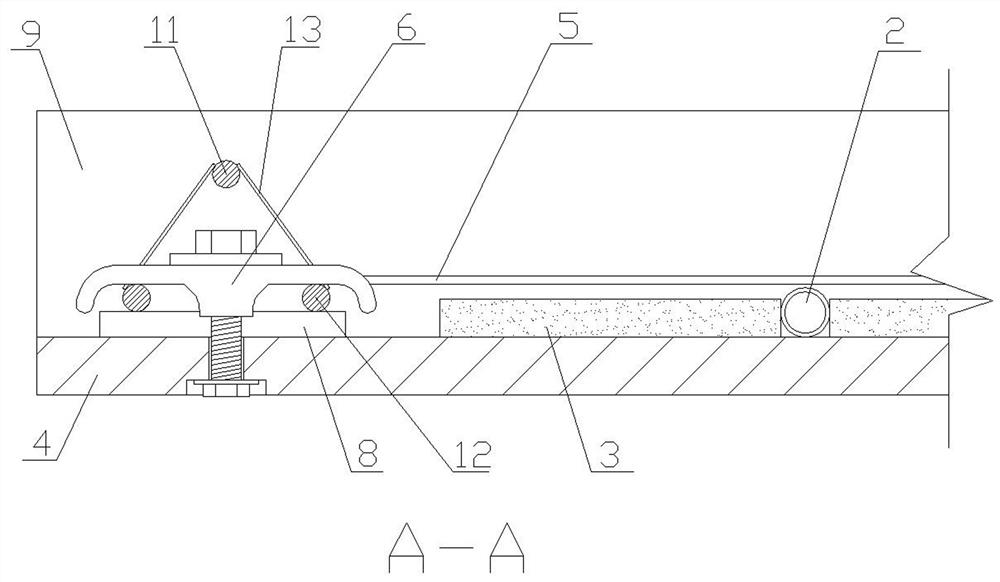

[0034] A multifunctional truss-supported floor slab and its construction method, using fiber cement board 4 as the bottom board, triangular trusses 1 fixed on the fiber cement board 4 as a skeleton, and the fiber cement board 4 spaces between the triangular trusses 1 are composed of steel bars 5 The steel mesh is fixed to the triangular truss 1, and several phase change material packages 3 are laid on the fiber cement board 4;

[0035] Several water pipes 2 are arranged between the phase change material packages 3, and the water pipes 2 are close to the phase change material packages 3;

[0036] The triangular truss 1 is fixed on the fiber cement board 4 using a pressing piece 6, and the pressing piece 6 is fastened on the preset through hole of the fiber cement board 4 using a screw and a nut;

[0037] A cushion block 8 is arranged under the triangular truss 1 to separate the triangular truss 1 from the fiber cement board 4;

[0038] The water pipe 2 is provided with a three...

Embodiment 2

[0048] The difference from Embodiment 1 is that the water pipe 2 is a galvanized iron pipe.

Embodiment 3

[0050] The difference from Embodiment 1 is that the water pipe 2 is a copper pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com