Construction method of high-precision formwork of cast-in-place fair-faced concrete wind tunnel

A technology of fair-faced concrete and construction method, which is applied in the direction of formwork/formwork/work frame, formwork/formwork member, formwork processing, etc., can solve the problems of poor control accuracy, etc. The effect of assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

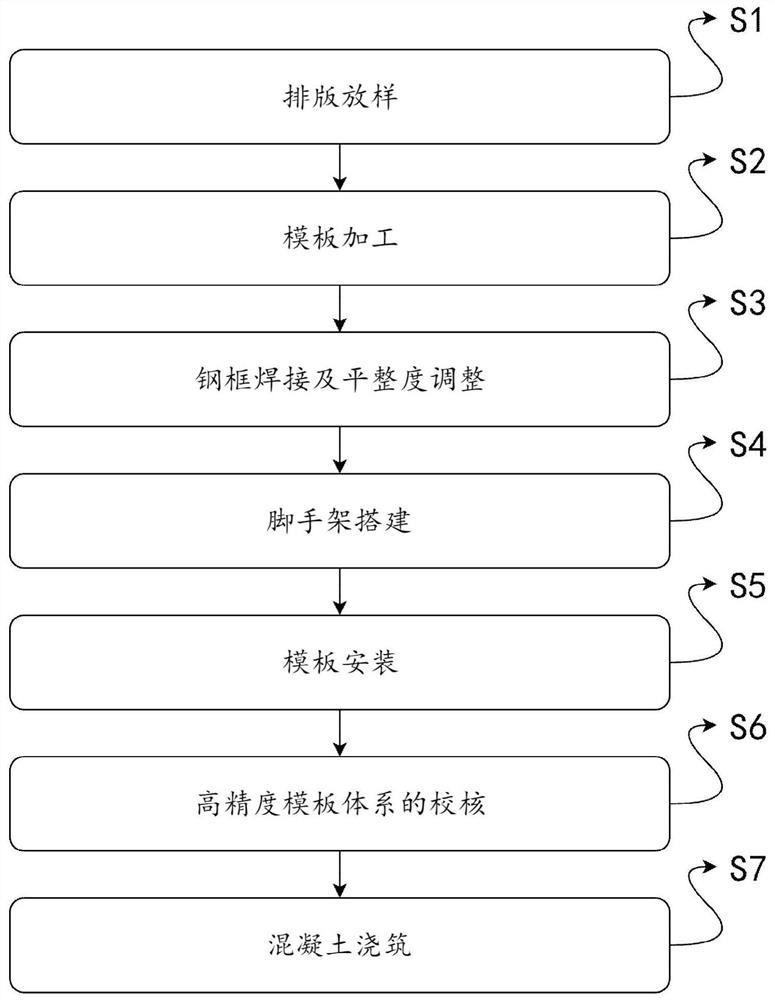

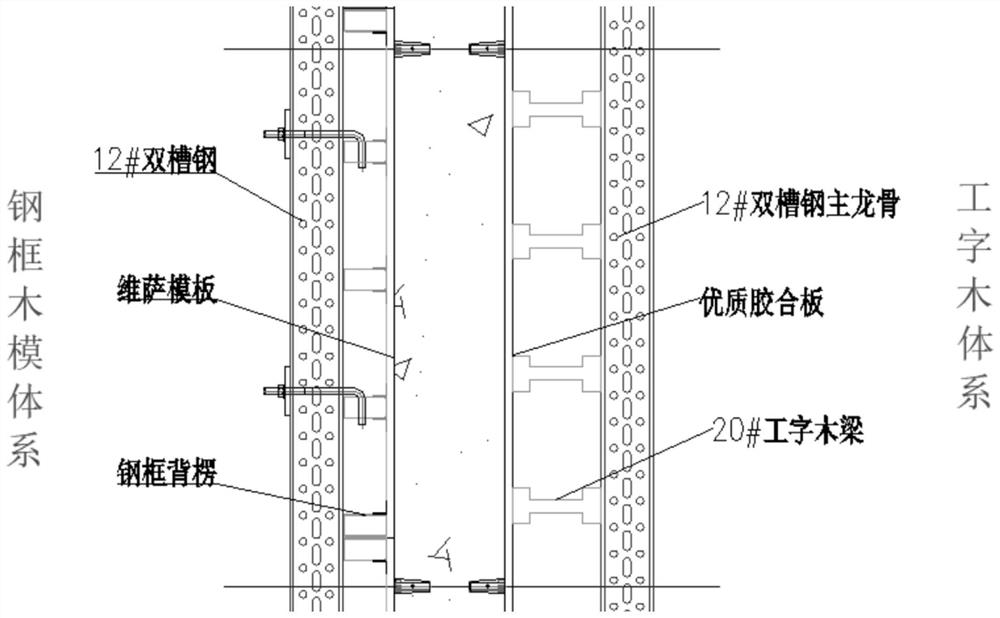

[0058] Such as Figure 1-14 As shown, the construction method of high-precision formwork of cast-in-place fair-faced concrete wind tunnel includes the following steps:

[0059] S1, typesetting and setting out, using BIM modeling and typesetting, precisely controlling the position and installation of each formwork and full frame, ensuring that the accuracy is controlled within 1mm;

[0060] Wherein, step S1 includes:

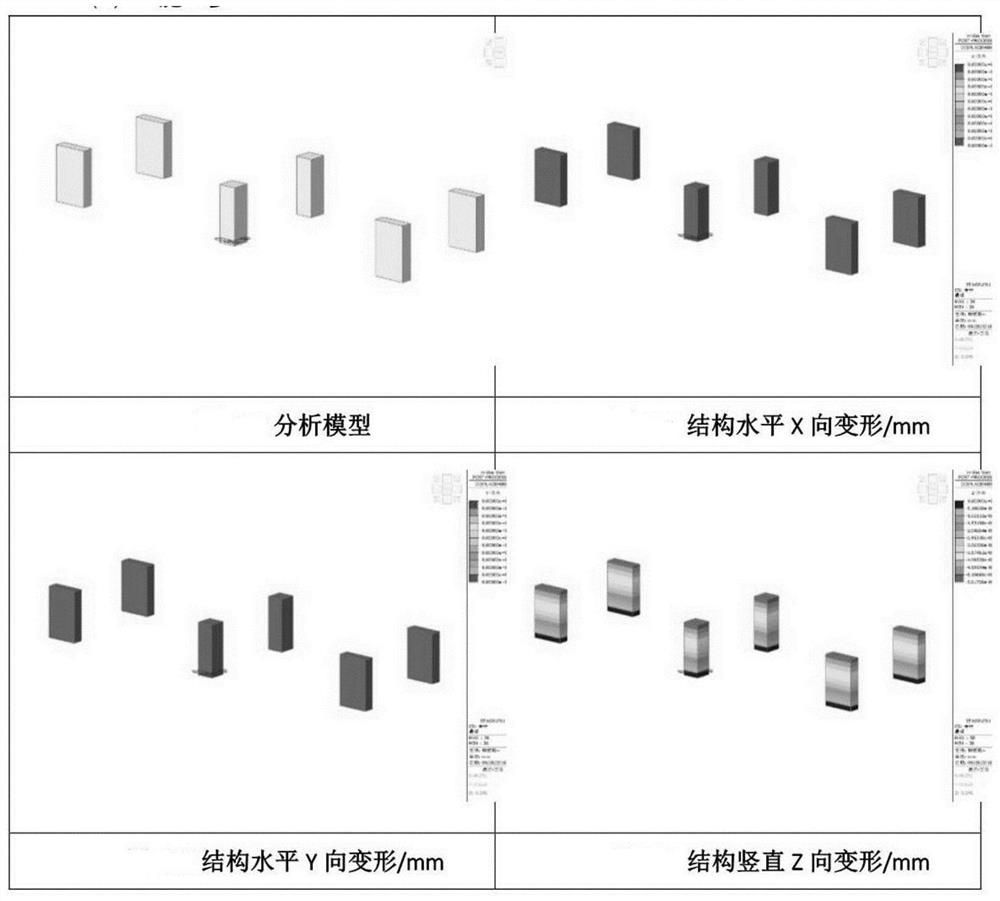

[0061] S1a, modeling, build a model according to the construction deployment of the model section, such as Figure 14 The wind tunnel finite element model shown,

[0062] S1b, conduct analysis and typesetting, conduct analysis and calculation of mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com