Two-position four-way electromagnetic ball valve

An electromagnetic ball valve, two-position four-way technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of affecting sealing performance, high cost, severe coil heating, etc., to improve service life, low manufacturing cost, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

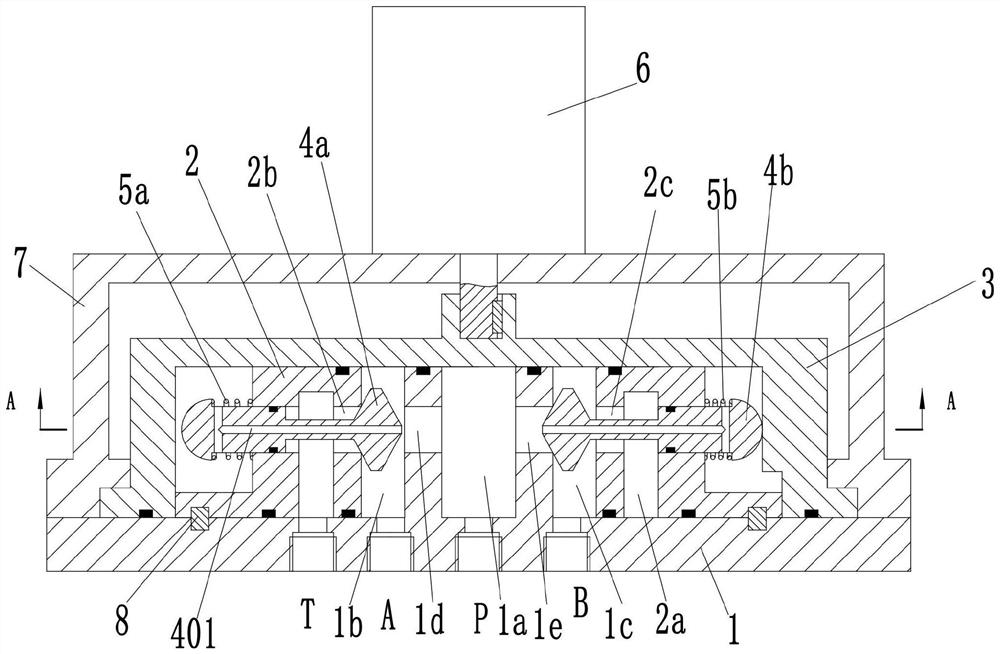

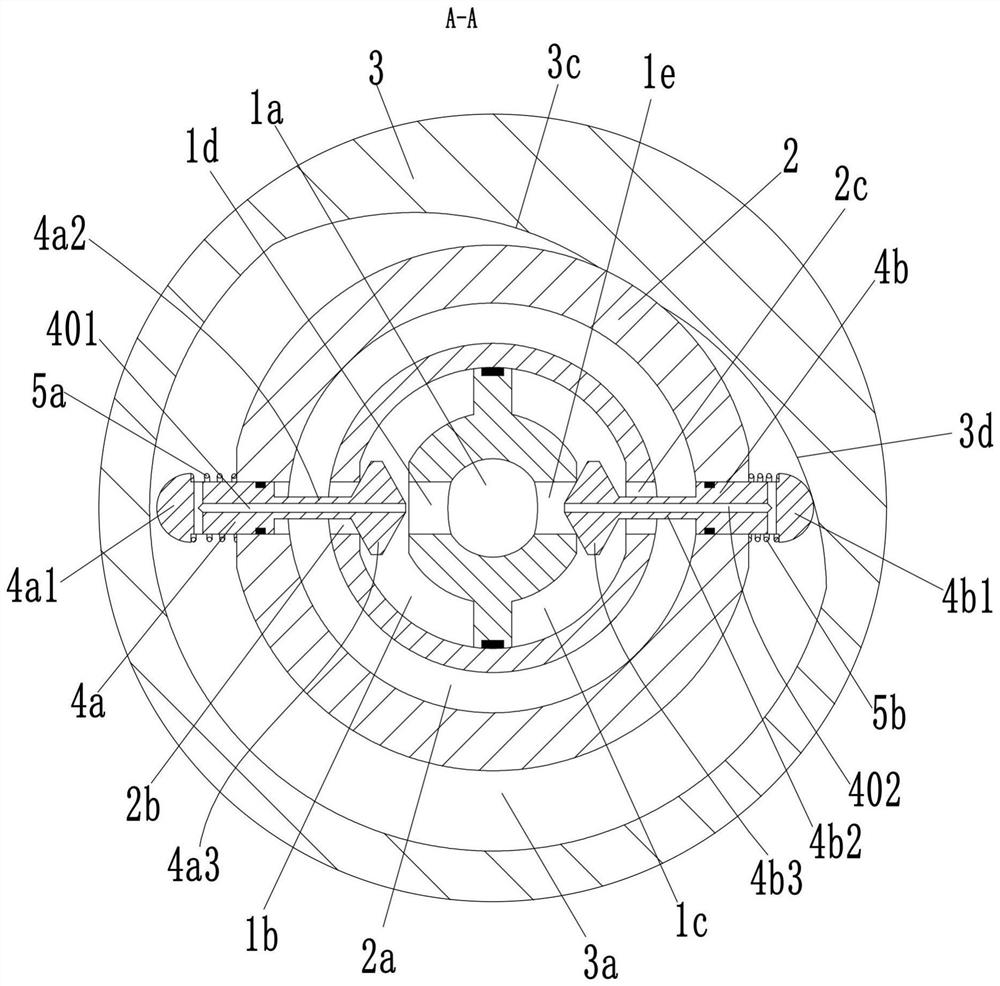

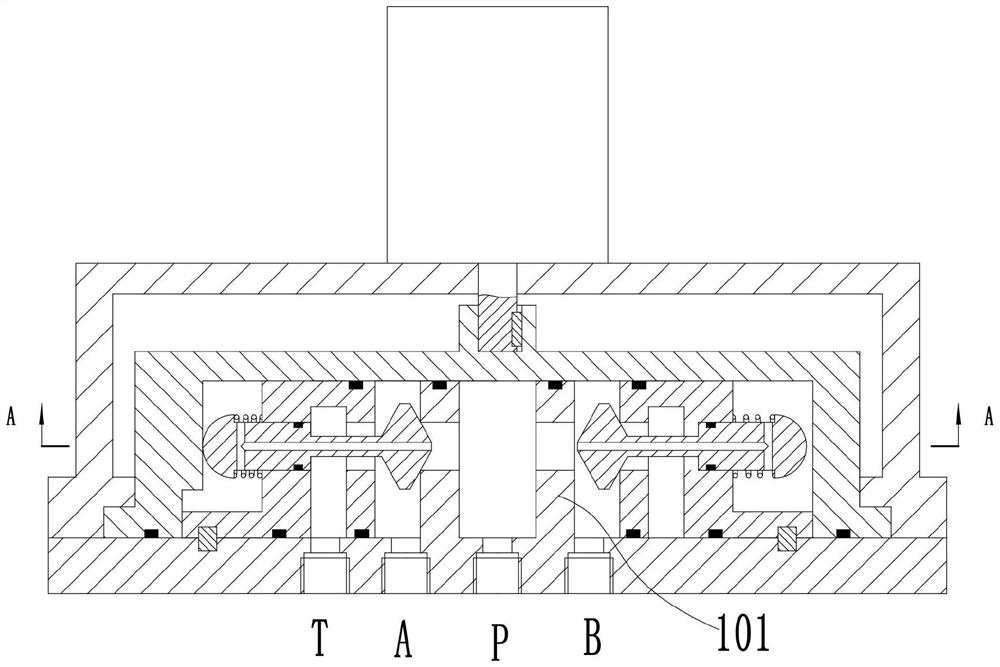

[0023] see Figure 1-4 As shown, the present invention provides a two-position four-way electromagnetic ball valve, including a valve housing 7, a bottom plate 1 is fixedly installed at the opening of the lower end of the valve housing 7, and the center of the bottom plate 1 is provided with a valve extending upward into the valve housing 7. The convex post 101 inside, the bottom plate 1 is fixed with the convex ring 2 centered on the convex post 101; the side of the convex post 101 is symmetrically provided with a convex edge 102 that interferes with the side wall of the inner ring of the convex ring 2; A central chamber 1a with an open upper end is provided in the convex column 101, and a left chamber 1b and a right chamber 1c are formed between the outer circumference of the convex column 101 and the inner ring side of the convex ring 2, and the convex ring 2 is provided with a The first annular cavity 2a, the bottom of the bottom plate 1 is provided with a P port communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com