Heat dissipation assembly for electronic product production and using method thereof

A technology for electronic products and heat-dissipating components, applied in the field of heat-dissipating components used in the production of electronic products, can solve the problems of deformation of electronic products, low cooling efficiency, easy occurrence of airflow, etc., and achieve the effect of increasing specific heat capacity, reducing time, and improving the rate of dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

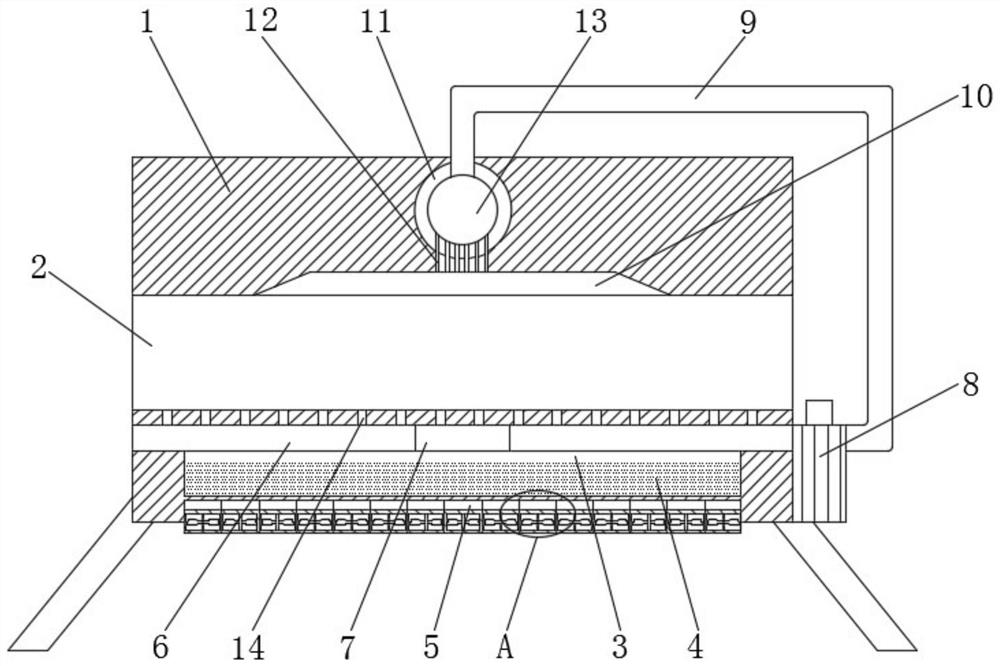

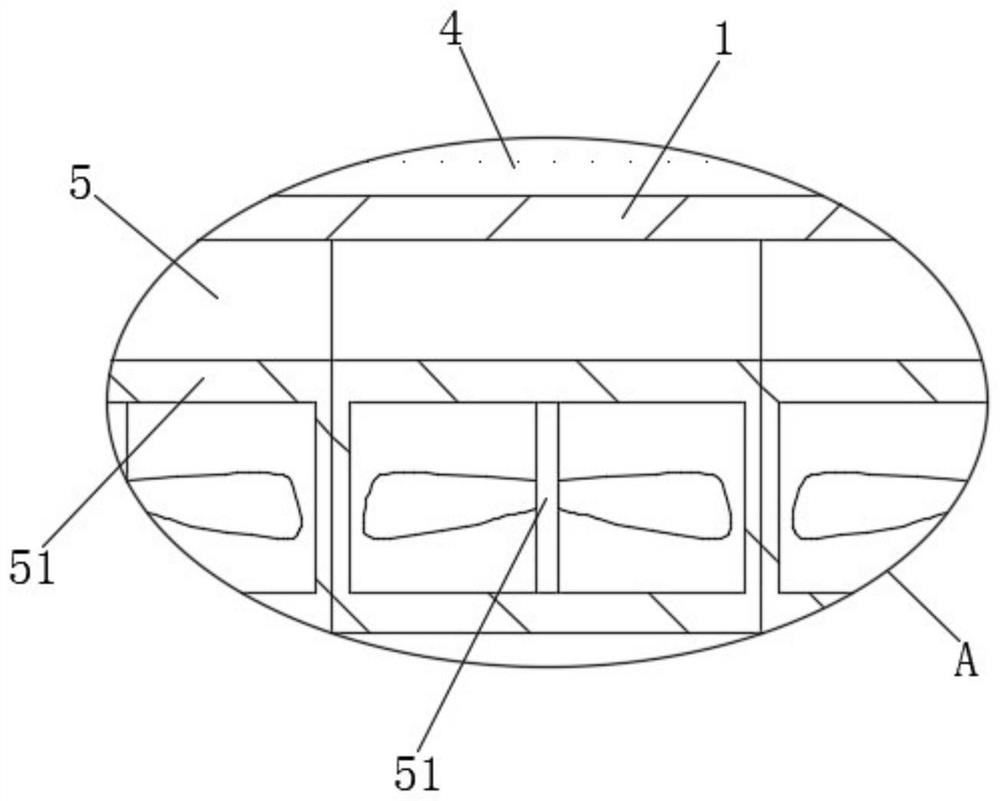

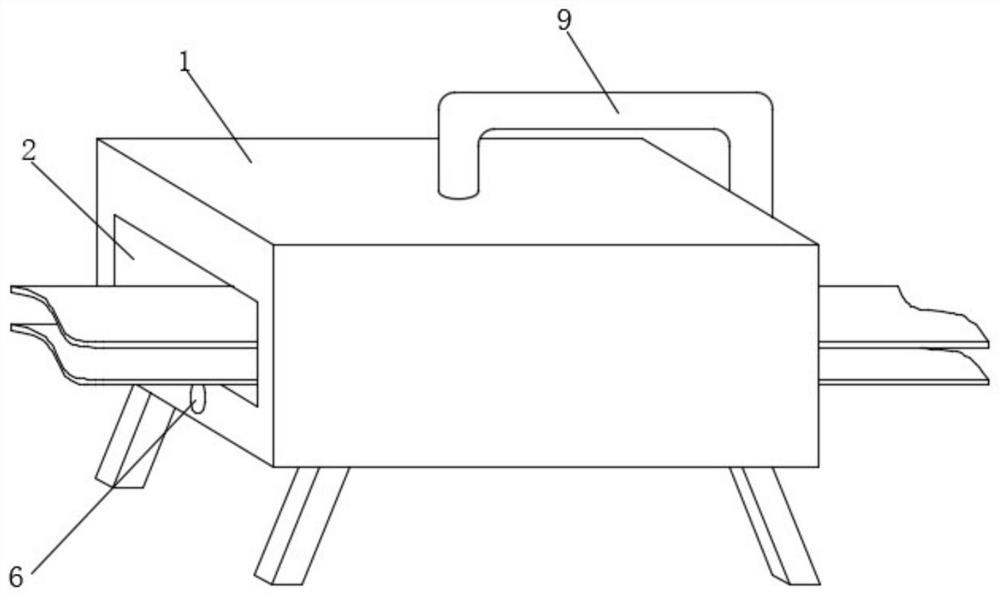

[0027] see Figure 1-4 , the present embodiment provides a heat dissipation assembly for the production of electronic products and its use method, including a fixed table 1, the inside of the fixed table 1 is provided with a transmission chamber 2 along the horizontal direction, and the interior of the fixed table 1 is directly above the transmission chamber 2 An air duct 10 is provided, and a water tank 3 is provided on the inside of the fixed platform 1 near the center and directly below the transmission chamber 2 , and the inside of the water tank 3 is filled with a coolant 4 .

[0028] The air bag 13 is connected directly above the air channel 10 through the air duct 12, the air bag 13 is connected to the air pump 8 through the air channel 9, and the suction end of the air pump 8 is connected to the air chamber 6 arranged directly above the water tank 3, and the air pump 8 and the air chamber 6 utilize a siphon The principle is to extract the coolant 4 inside the water tan...

Embodiment 2

[0041] see figure 1 , made further improvement on the basis of Embodiment 1: the buffer chamber 11 is a hollow spherical structure, the inside of the buffer chamber 11 is equipped with an airbag 13, the outer wall of the top side of the airbag 13 is connected with the end of the airway 9, and the bottom of the airbag 13 The outer wall of the side is connected with the top of the air duct 12. There are multiple air ducts 12 arranged in an array on the inner wall of the top side of the air duct 10. The air bag 13 can expand when the air pump 8 is running, and pass through Its own deformation can ensure a more uniform airflow. When the air pump 8 stops running, the inflated airbag 13 can use its own elastic potential energy to accelerate the airflow to a certain extent and slow down the rate of airflow change, thereby preventing electronic products from being subjected to strong airflow. The influence of unevenness appears.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com