Metal-based printed circuit board

A printed circuit board, metal-based technology, used in printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve the problem that the thermal conductivity of the insulating layer cannot effectively utilize the heat dissipation capacity of the metal-based electronic components, and achieve accelerated heat dissipation. The rate of heat dissipation, the effect of accelerating heat exchange and enhancing heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

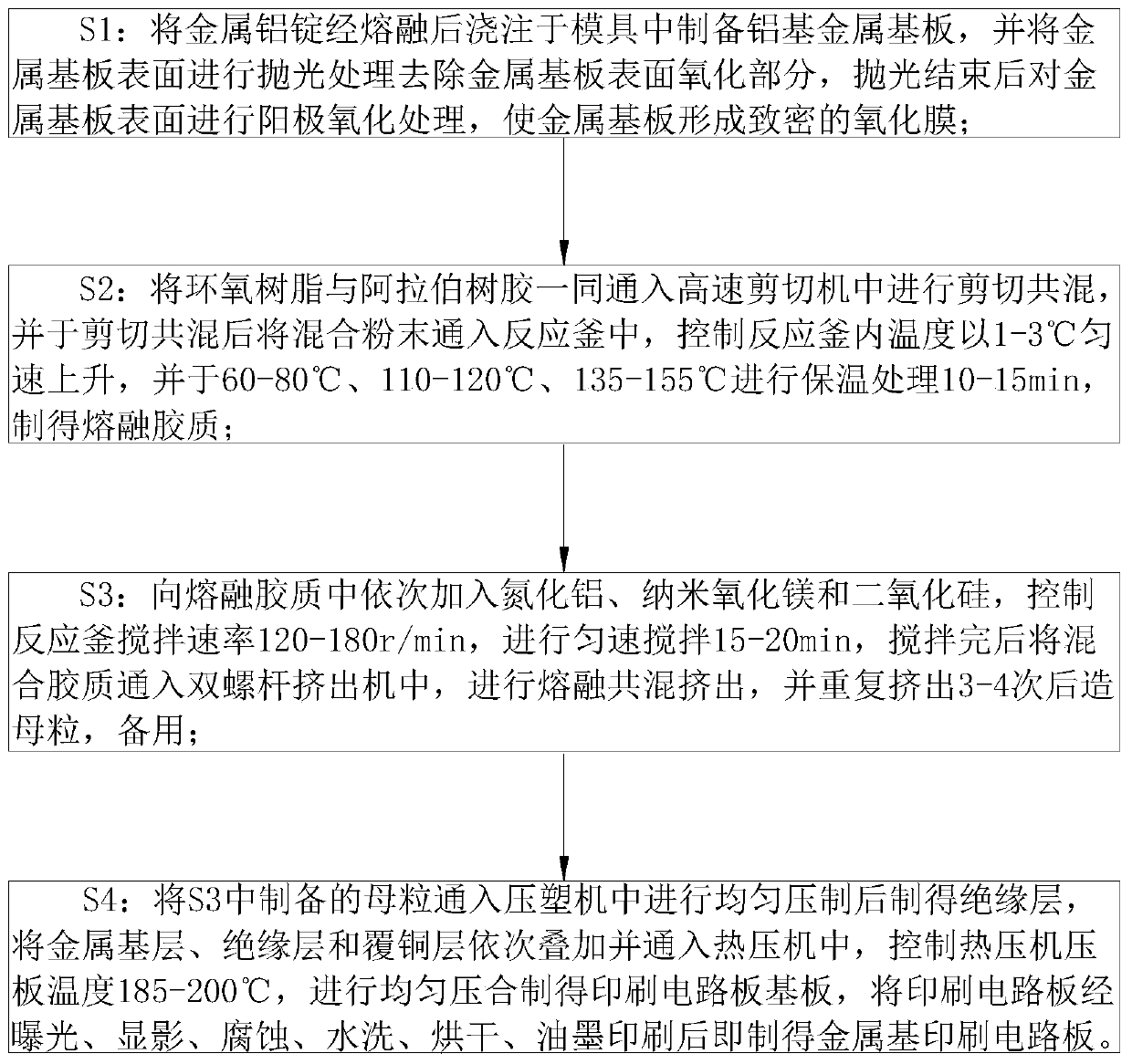

[0034] The preparation method of the metal-based printed circuit board comprises the following steps:

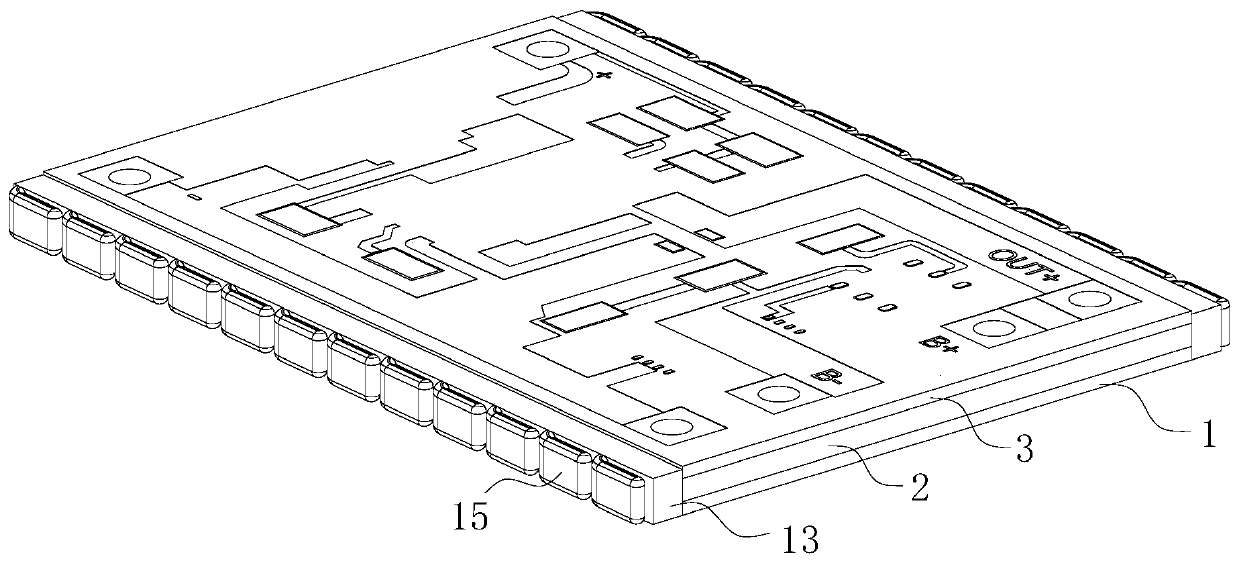

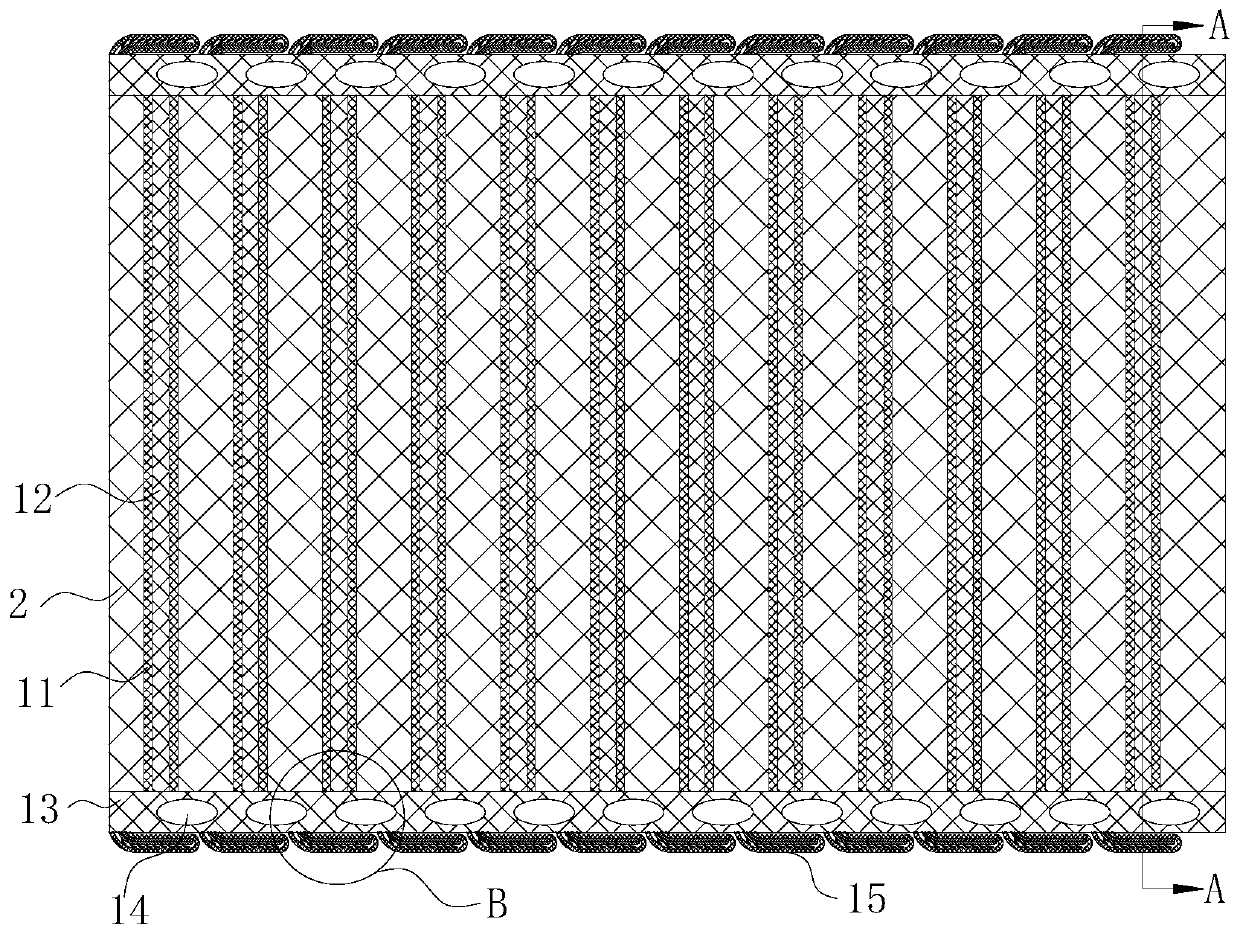

[0035] S1: melting the metal aluminum ingot and pouring it into a mold to prepare the aluminum-based metal base 1, and polishing the surface of the metal base 1 to remove the oxidized part of the metal base 1 surface, and performing anodic oxidation treatment on the surface of the metal base 1 after polishing, Make the metal base layer 1 form a dense oxide film; polish the surface of the metal base layer 1 to remove the aluminum oxide film layer naturally formed on the surface, and form a relatively dense oxide film layer through anodic oxidation, so that the formed aluminum oxide film structure is more compact It is denser and smoother. At the same time, the use of anodic oxidation treatment can also make the formed aluminum oxide film itself have strong adsorption performance, so that the metal base layer 1 and the insulating layer 2 resin are more closely combined, effecti...

Embodiment approach

[0043]As an embodiment of the present invention, an elastic sheet 17 is fixedly connected to the side of the deformation sheet 16 away from the heat dissipation pad 13; the elastic sheet 17 is made of a thermal bimetallic material with a high thermal expansion coefficient. The side is close to the deformation sheet 16; when working, the temperature of the deformation sheet 16 rises, thereby causing bending, so that the heat sink 15 and the heat dissipation pad 13 are separated, thereby increasing the heat dissipation area, and at the same time, the elastic sheet 17 and the deformation sheet 16 are fixed to each other. Even, when the deformation sheet 16 heats up, the elastic sheet 17 is also deformed. At this time, the force of the deformation of the elastic itself matches the bending force of the deformation sheet 16 to form a squeeze on the side of the heat sink 15 away from the heat dissipation pad 13, so that the surface of the heat sink 15 Regular protrusions are formed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com