Zero-speed injector test method for engine cold test

A test method and engine technology, applied in the direction of engine testing, machine/structural component testing, instruments, etc., can solve problems such as damage to the main servo motor of the equipment, low detection ability, and disengagement of the safety clutch of the equipment, so as to reduce the system error. , Improve consistency and avoid contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the test object is a 4-cylinder diesel engine, and the concrete test steps are as follows:

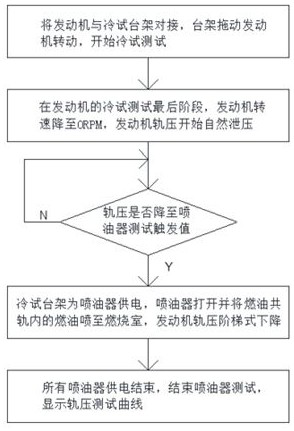

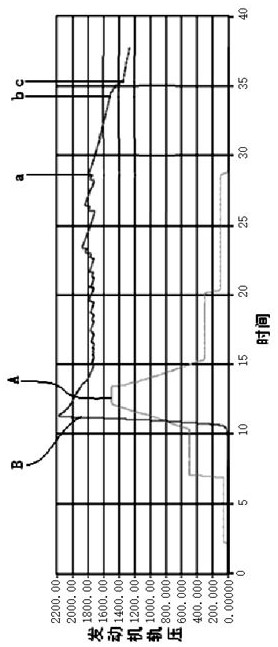

[0043] Step 1: The engine is successfully docked with the cold test bench, and the bench drags the engine to rotate to start the conventional cold test test. The engine speed changes are: 0RPM→60RPM→500RPM→1500RPM→300RPM→100RPM→0RPM, as attached figure 2 The middle curve A is shown.

[0044] Step 2: In the final stage of the cold test test of the engine, the engine speed drops to 0RPM, and the engine rail pressure begins to depressurize naturally, as shown in the appendix. figure 2 Phases a-b on the middle curve B are shown.

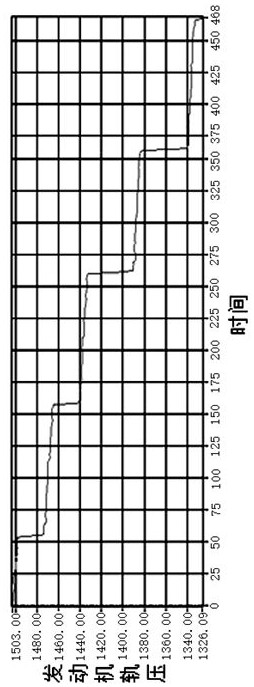

[0045] Step 3: The cold test bench detects the engine rail pressure in real time through the engine rail pressure sensor. In this embodiment, the fuel injector test trigger value is calibrated to 1500Bar. When the engine rail pressure drops to 1500Bar, the fuel injector test starts.

[0046] Step 4: The cold test bench supplies power to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com