Vapor-water sampling suspended iron and ionic iron separation device and corresponding iron content determination method

A separation device and technology for iron content, applied in the field of soda water sampling suspended iron and ion iron separation devices, can solve the problems of short sampling time, low scaling rate of water supply system, very large difference of scaling rate of water supply system, etc. Effects of Representativeness and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

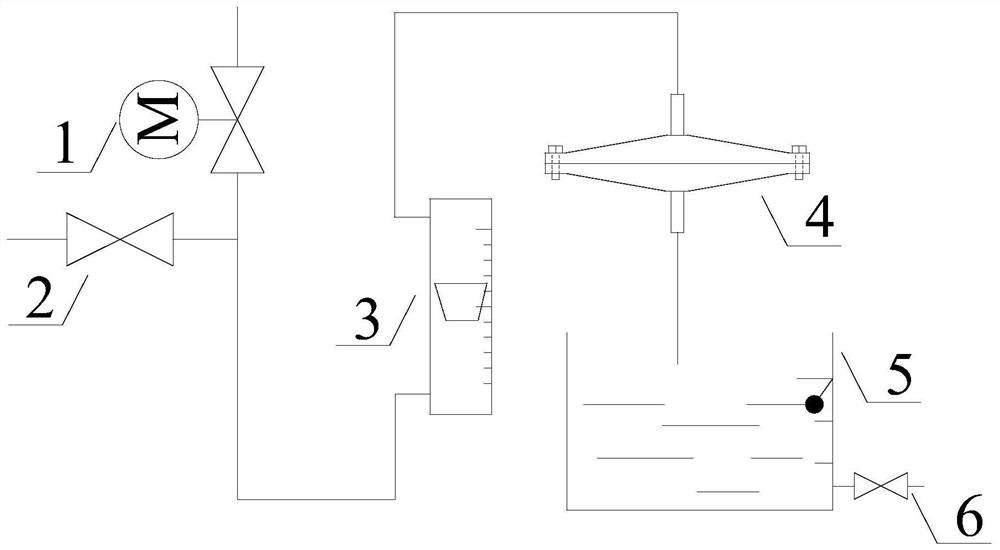

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] Before sampling, open the flat filter 4, lay a 0.45 μm cellulose filter membrane on the porous plate of the lower conical cover of the flat filter, install the sealing ring, cover the upper conical cover, and fasten the bolts to install the flat filter. Enter the suspended iron and ion iron separation device.

[0025] Such as figure 1 As shown, connect the suspended iron and ionized iron separation device to the steam-water sampling point, fix the opening of the sampling flow regulating valve 1, and fine-tune the opening of the sampling bypass valve 2, so that the sampling flow through the sampling flow meter 3 is 10L / h , the water sample of the same flow is filtered through the flat filter 4, and the filtrate enters the quantitative sampling barrel 5, and the suspended iron is trapped on the cellulose filter membrane of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com