Adiabatic fixed bed reactor and reaction method

An adiabatic fixed bed and reactor technology, applied in the field of reactors, can solve the problems of low propylene selectivity, high material gasification rate, loss of propylene selectivity, etc., and achieve the effect of improving hydrogenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

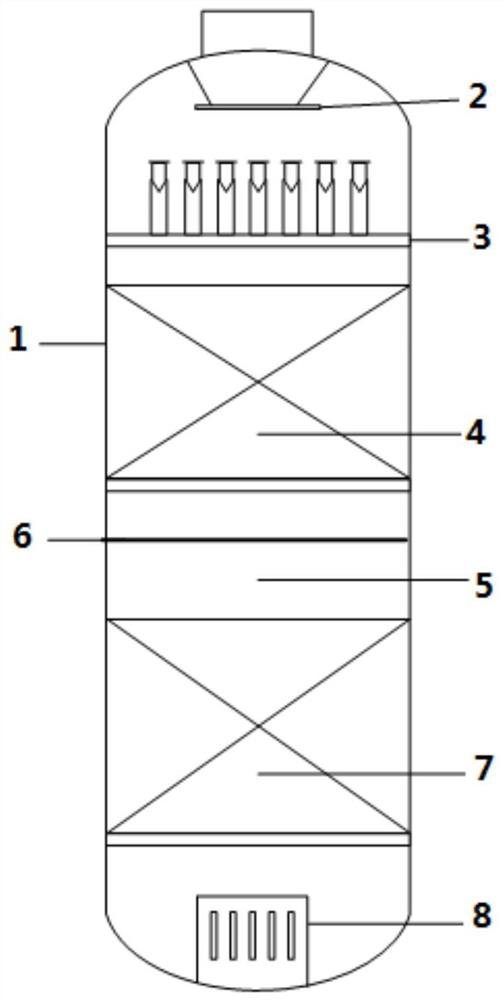

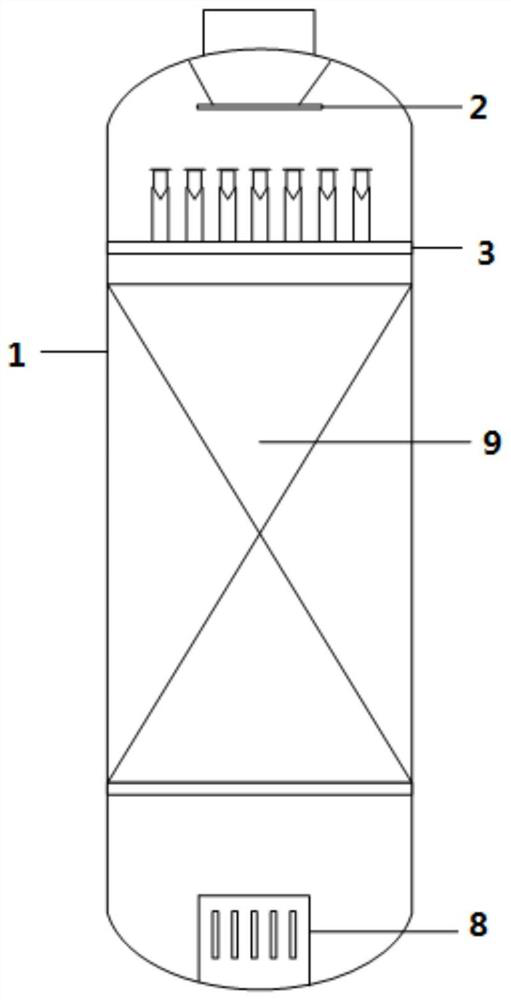

[0042] Such as figure 1 As shown, an adiabatic fixed-bed reactor includes a cylinder 1, a pre-distributor 2, a gas-liquid distribution plate 3, a catalyst bed, and an outlet concentrator 8; the top of the cylinder 1 is provided with an inlet; the adiabatic fixed-bed reaction Inside the device, a pre-distributor 2, a gas-liquid distribution plate 3, a catalyst bed and an outlet collector 8 are arranged sequentially from top to bottom along the axial direction of the cylinder;

[0043] The catalyst bed is arranged in two parts, the catalyst upper bed 4 and the catalyst lower bed 7, and the interlayer gap area 5 is set between the catalyst upper bed 4 and the catalyst lower bed 7;

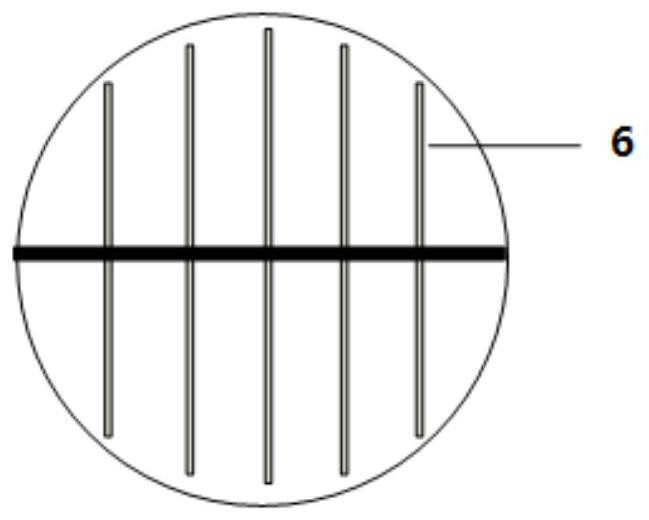

[0044] The upper part of the void area 5 is provided with a hydrogen distribution pipe 6 . The main pipe of the hydrogen distribution pipe 6 passes through the central axis of the reactor cylinder and both ends are connected to the reactor wall, one of which is connected to the external hydrogen dist...

Embodiment 2

[0048] A kind of adiabatic fixed-bed reactor, with embodiment 1, difference only lies in:

[0049] The upper part of the void area 5 is provided with a hydrogen distribution pipe 6 . The main pipe of the hydrogen distribution pipe 6 passes through the central axis of the reactor cylinder and both ends are connected to the reactor wall, one end of which is connected to the external hydrogen distribution pipeline. There are 7 branch pipes of the hydrogen distribution pipe 6, all of which are horizontal and radial are connected vertically and connected internally. The arrangement sequence of the 6 branch pipes of the hydrogen distribution pipe is as follows: one branch pipe is set at the center of the main pipe, and then one branch pipe is arranged at an interval of 0.25 meters on both sides of the main pipe, and a total of 7 branch pipes are set. The length of the branch pipes of the hydrogen distribution pipe 6 is set to four specifications of 1.80 meters, 1.73 meters, 1.50 me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com