Cement material producing and processing device

A processing device and material technology, applied in grain processing, food science, drying gas arrangement, etc., can solve the problems of reduced cement effect, uneven crushing of limestone and other raw materials, so as to improve the uniformity of mixing, avoid mutual adhesion, and ensure drying effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

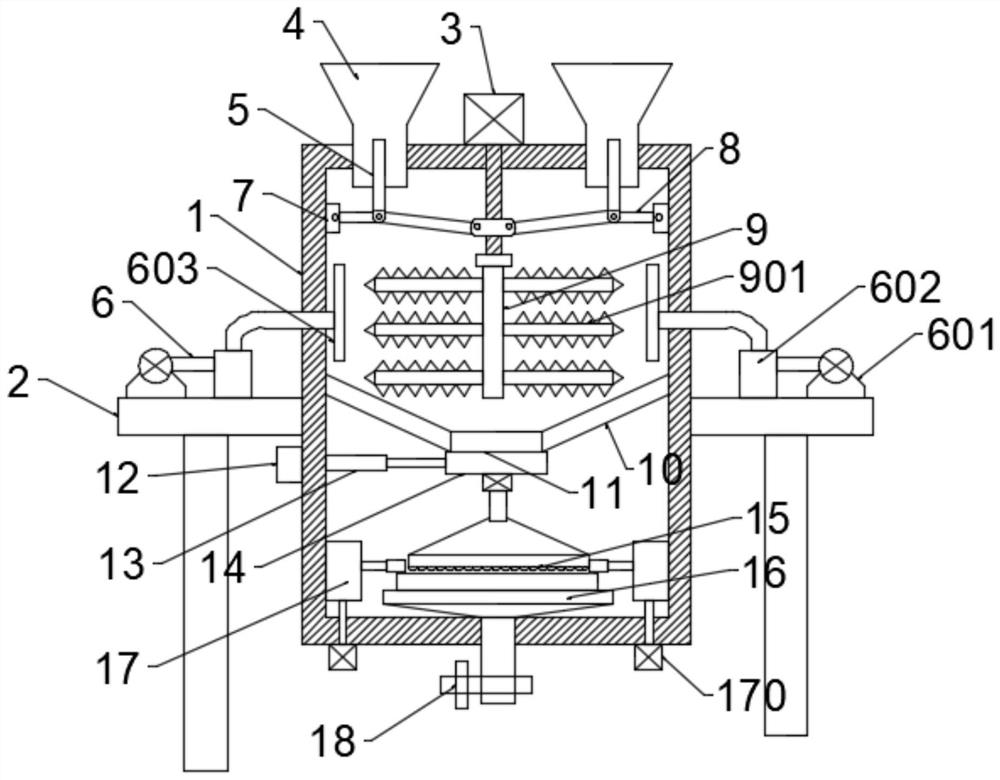

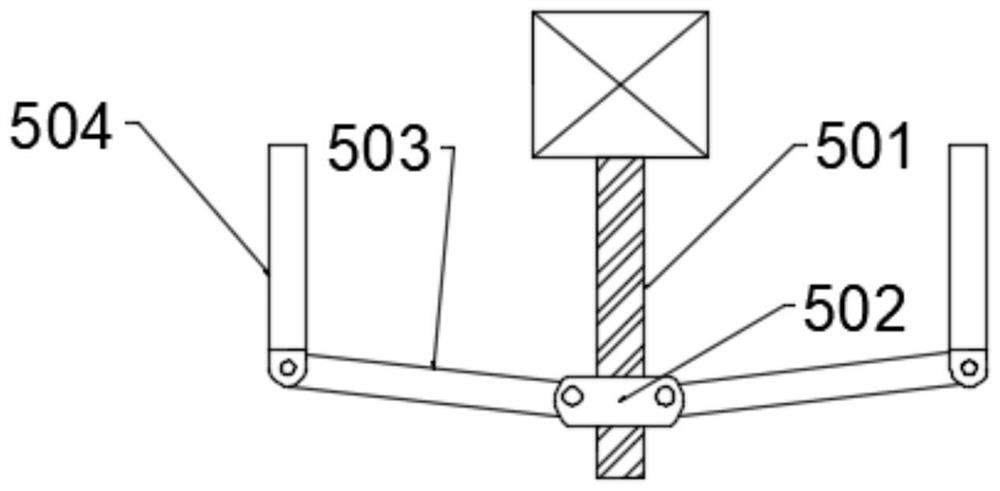

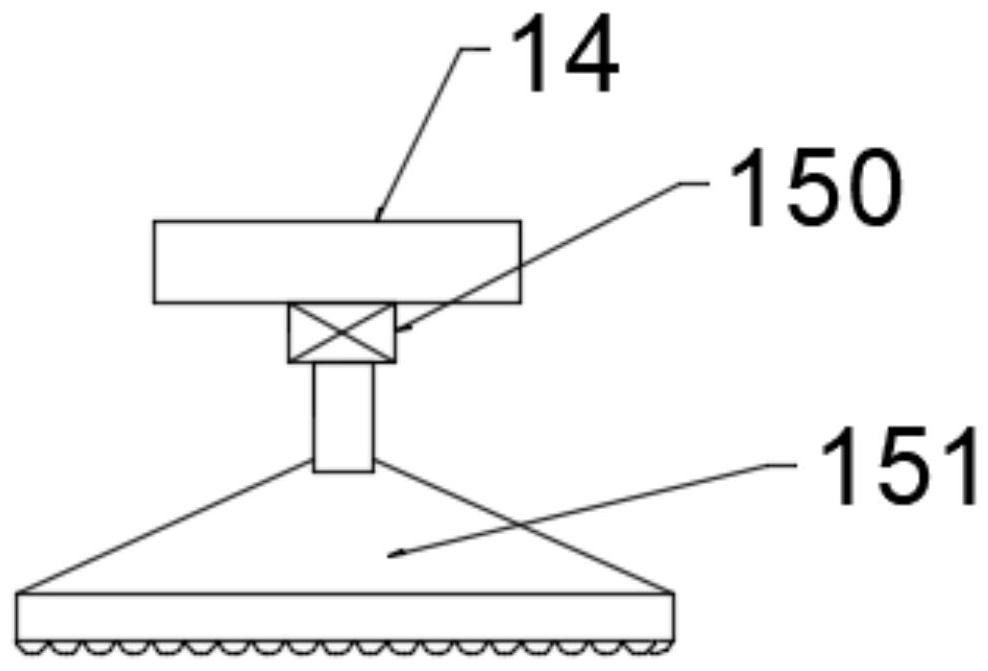

[0026] see Figure 1-3 , in an embodiment of the present invention, a cement material production and processing device includes a processing box 1, a horizontal plate 2 is provided on the outer surface of the middle part of the processing box 1, and the bottom end of the horizontal plate 2 is fixedly supported by a support frame. The left and right ends of the plate 2 close to the processing box 1 are provided with a drying mechanism 6, the middle part of the top of the processing box 1 is fixedly equipped with a drive motor 3, and the left and right sides of the drive motor 3 are respectively provided with a feed funnel 4, so The left and right ends of the top of the processing box 1 are provided with feed ports, the feed ports communicate with the feed funnel 4, and the inside of the feed funnel 4 is provided with a dredging mechanism 5, and the dredging mechanism 5 includes a screw rod 501. The output shaft of the driving motor 3 is fixedly connected with a screw mandrel 50...

Embodiment 2

[0031] see Figure 1-4, in this embodiment, the drying device 6 includes a blower 601, a heating box 602 is installed on one side of the blower 601, and an electric heating wire is installed in the heating box 602. Between the blower 601 and the heating box 602 A first conveying pipe is communicated, and one end of the heating box 602 is fixedly connected with a second conveying pipe, and a mounting hole is opened on a side of the processing box 1 close to the second conveying pipe, and the second conveying pipe passes through the mounting hole and One end is fixedly connected with a heating pipeline 603, the heating pipeline 603 is close to the side wall of the processing box 1, and a heating hole is opened in the heating pipeline 603, and the blower 601 is started, and the blower 601 flows into the heating box 602 through the first delivery pipe. Air is transported, and the heat source is released by heating the heating wire in the heating box 602, so that the gas is heated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com