Spraying template, manufacturing method and method for manufacturing identification by using spraying template

A production method and template technology, applied in the field of sign spraying, can solve the problems of low installation position, inconvenient viewing, and difficult to find, etc., and achieve the effects of improving service life, avoiding dislocation of spraying content, and avoiding virtual edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

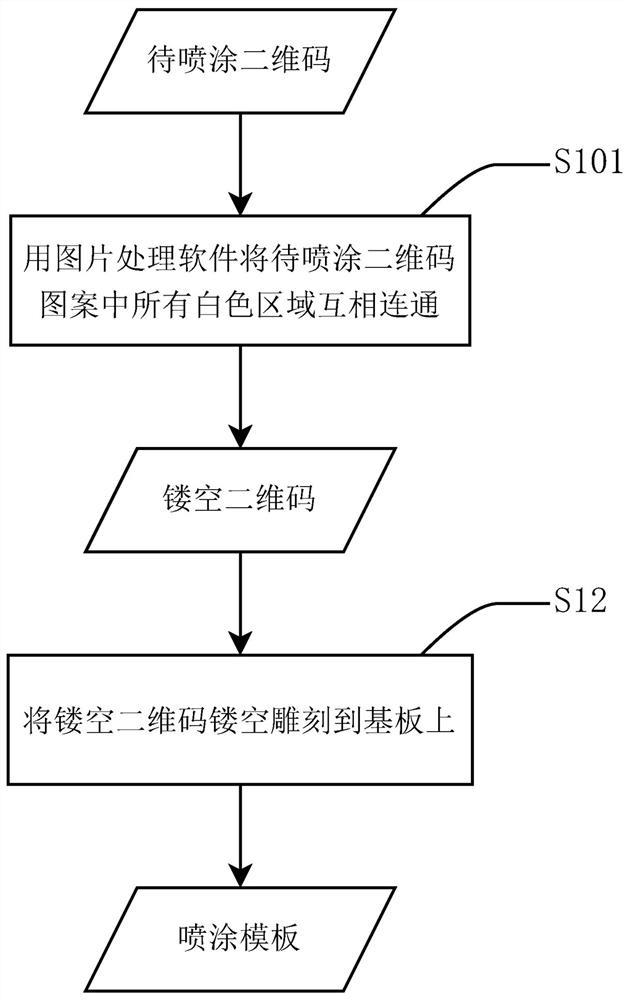

[0048] The purpose of this embodiment 1 is to provide a kind of preparation method of spray template, as figure 2 As shown, the coating template preparation method that the present embodiment provides spraying comprises:

[0049] Step S11, making a hollow two-dimensional code, the hollow two-dimensional code is a QR code, which can be hollowed out and set on the substrate.

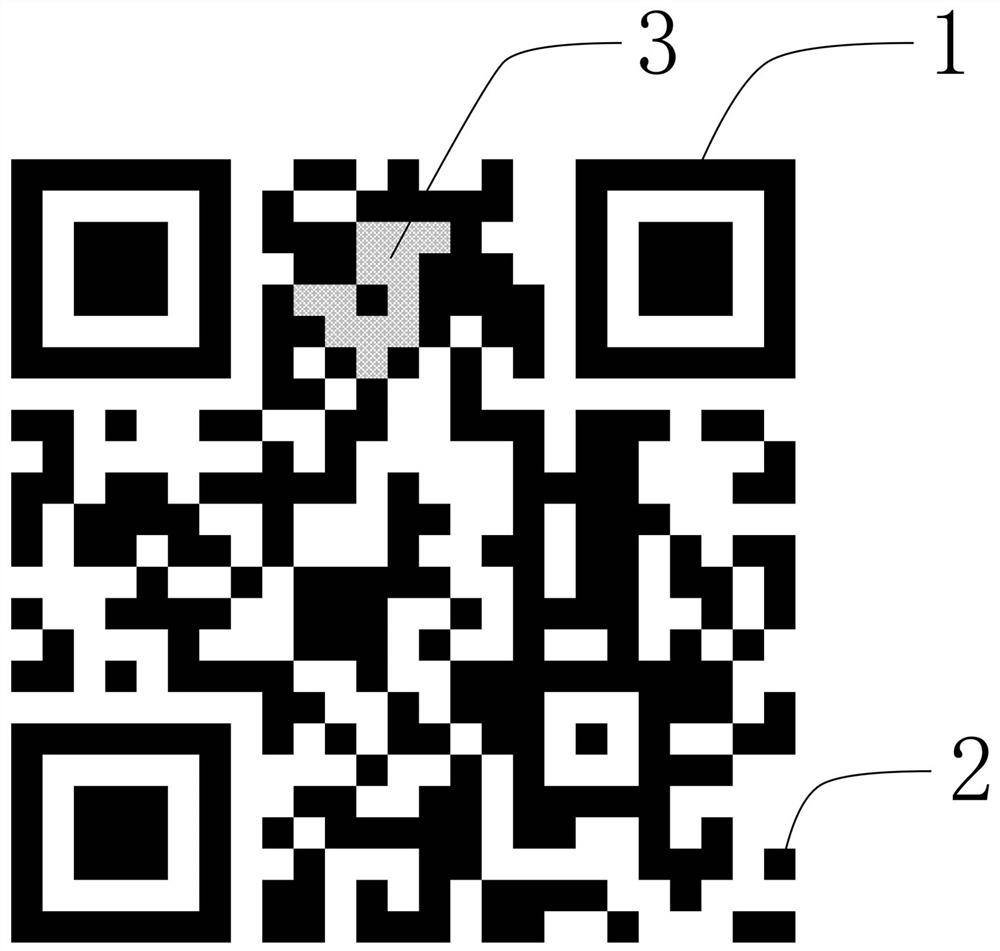

[0050] The two-dimensional codes described in the present invention are all figure 1 The QR code shown is square, usually in black and white (white is the background color, black is the foreground color), and is composed of multiple black square code points 2 filled; the upper left corner, upper right corner, and lower left corner of the QR code Positioning areas are set respectively, and the frame of the positioning areas is the positioning frame 1 .

[0051] However, there are many independent white areas similar to the white color block 3 in the two-dimensional code. If the two-dimensional code is di...

Embodiment 2

[0057] The purpose of this embodiment 2 is to provide a kind of preparation method of spray template, as Figure 4 As shown, compared with Example 1, the spray template manufacturing method provided in this embodiment has been further improved as follows:

[0058] The method for making a hollow two-dimensional code in the step S11 includes:

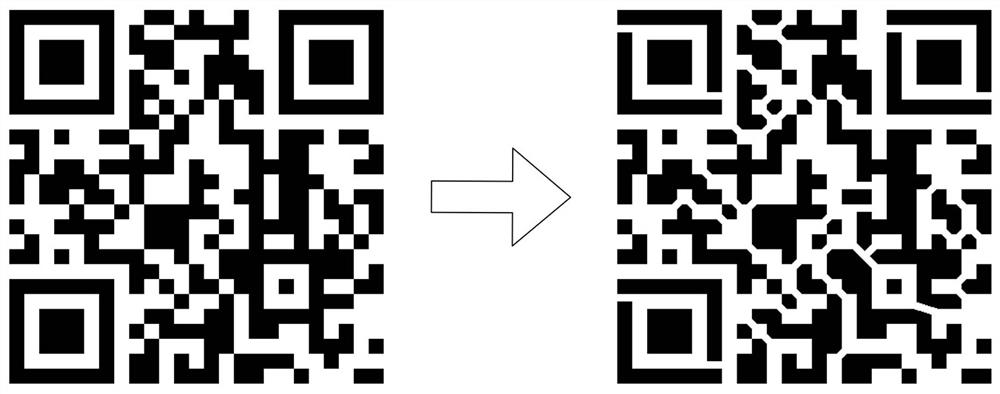

[0059] 1. Step S201, generating a two-dimensional code pattern with intervals between code points according to the content to be sprayed.

[0060] At present, there are many tools for generating two-dimensional codes of special shapes on the Internet, and by using these tools, two-dimensional code patterns with intervals between code points can be generated.

[0061] like Figure 5 Shown is the interface of an online website for generating QR code patterns. The website can generate a variety of QR code patterns with intervals between code points according to the content to be sprayed. The white background of the area where the code poin...

Embodiment 3

[0065] The purpose of this embodiment 3 is to provide a kind of preparation method of spray template, as Figure 7 As shown, compared with Example 1, the spraying stencil manufacturing method provided in this embodiment has been further improved as follows:

[0066] The method for making a hollow two-dimensional code in the step S11 includes: step S301, using a computer program to directly generate the hollow two-dimensional code according to the content to be sprayed.

[0067] Specifically, such as Figure 8 As shown, the working steps of the computer program include:

[0068] 1. Step S311, according to the content to be sprayed, use the two-dimensional code generation algorithm to generate a two-dimensional matrix representing the two-dimensional code pattern.

[0069] In this embodiment, h represents the width of the final two-dimensional code (in pixels), n represents the number of code point rows of the final two-dimensional code, a represents the width of the code poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com