Detection system for flow valve machining and detection method thereof

A detection system and flow valve technology, which is applied in sorting and other directions, can solve the problems of false detection and missing detection, inconvenient traceability of the detection process, and low detection efficiency, so as to improve detection efficiency, prevent defective products from entering the market, and reduce manpower input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. It is obvious that the specific embodiments listed are only some embodiments, and those of ordinary skill in the art can obtain other embodiments without paying creative work. Embodiments all belong to the protection scope of the present invention.

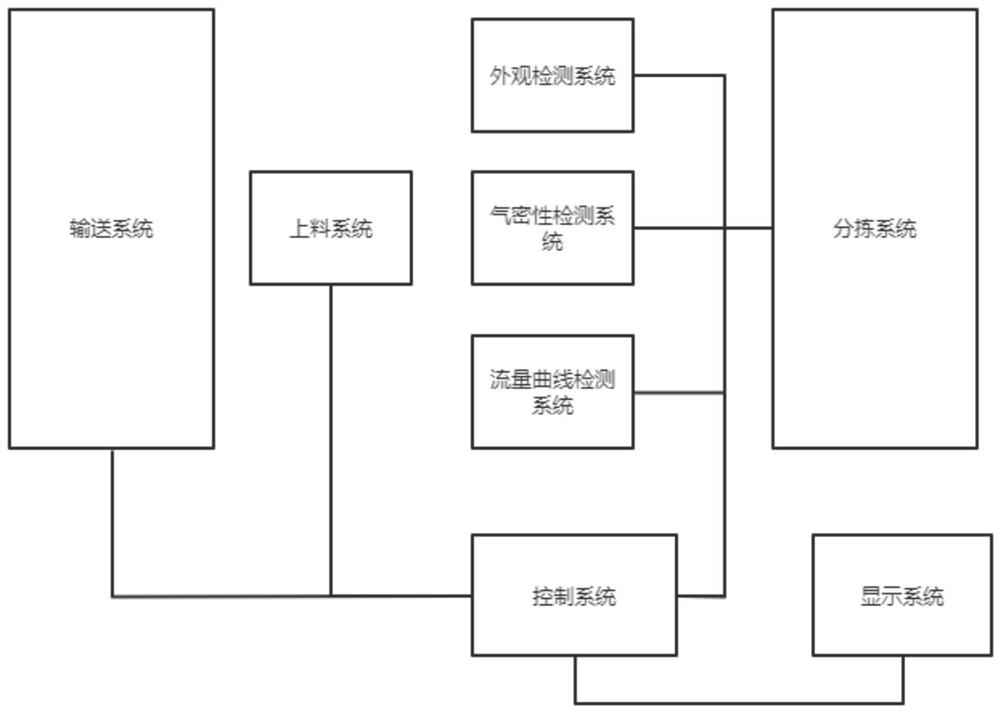

[0057] refer to figure 1 , a detection system for flow valve processing in a preferred embodiment of the present invention, including a conveying system, a feeding system, an appearance detection system, an air tightness detection system, a flow curve detection system, a sorting system, a display system and control system, where:

[0058] The conveying system is used to receive the processed flow valve and transport the flow valve to the feeding area;

[0059] The feeding system is used to transfer the flow valve located in the feeding area to the appearance inspection system, the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com