Cooling process for manufacturing cracking connecting rod blank from 38MnVS6 medium-carbon non-quenched and tempered steel

A cooling process, non-quenched and tempered steel technology, used in manufacturing tools, heating/cooling equipment, metal processing equipment, etc. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

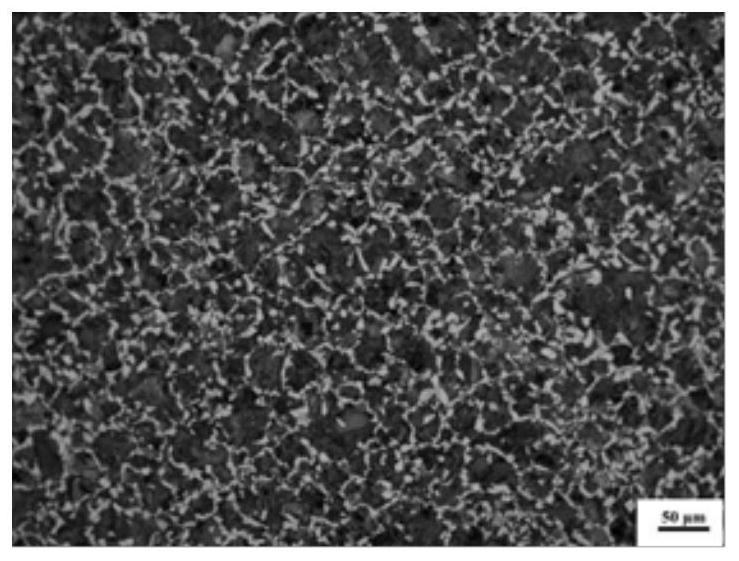

Image

Examples

Embodiment 1

[0023] After the connecting rod blank is forged, it is treated with a controlled cooling process, specifically:

[0024] (1) Rapid cooling in the box furnace: place the forged 38MnVS6 connecting rod blank on the suspension chain, and pass through the box furnace at a controlled speed of 2m / min. The blower is fully turned on at 30HZ, and the suction fan is fully turned on at 50HZ. , the cooling rate is controlled at 2.4°C / S, the temperature of the connecting rod blank before rapid cooling is 890°C, and it is rapidly cooled to 680°C in the box furnace;

[0025] (2) Slow cooling in the box furnace: the connecting rod blank enters the slow cooling zone in the box furnace from the rapid cooling zone in the box furnace, and the connecting rod blank is slowly cooled from 680 to 600 °C, and the cooling rate is controlled at 0.5 °C / S. The hair dryer and suction fan are all turned off;

[0026] (3) Slow cooling of the air outside the furnace: the connecting rod blank enters the outside...

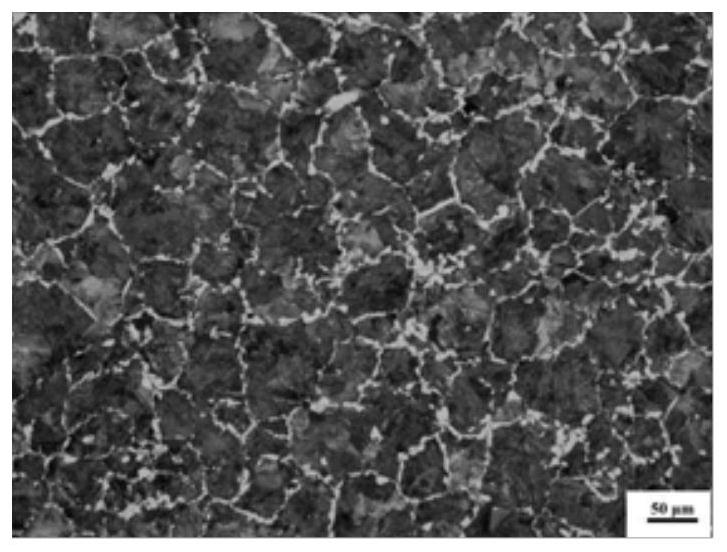

Embodiment 2

[0030] After the connecting rod blank is forged, it is treated with a controlled cooling process, specifically:

[0031] (1) Rapid cooling in the box furnace: place the forged 38MnVS6 connecting rod blank on the suspension chain, and pass through the box furnace at a controlled speed of 2m / min. The blower is fully turned on at 30HZ, and the suction fan is fully turned on at 50HZ. , the cooling rate is controlled at 1.5°C / S, the temperature of the connecting rod blank before rapid cooling is 850°C, and it is cooled to 700°C by rapid cooling in the box furnace;

[0032] (2) Slow cooling in the box furnace: the connecting rod blank enters the slow cooling zone in the box furnace from the quick cooling zone in the box furnace, and the connecting rod blank is slowly cooled from 700°C to 580°C, and the cooling rate is controlled at 0.57°C / S , the hair dryer and suction fan are all turned off;

[0033] (3) Slow cooling of the air outside the furnace: the connecting rod blank enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com