Additive manufacturing identical parallel machine scheduling method for selective laser melting process

A technology of additive manufacturing and laser selection, which is applied in the direction of additive manufacturing, additive processing, manufacturing computing systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

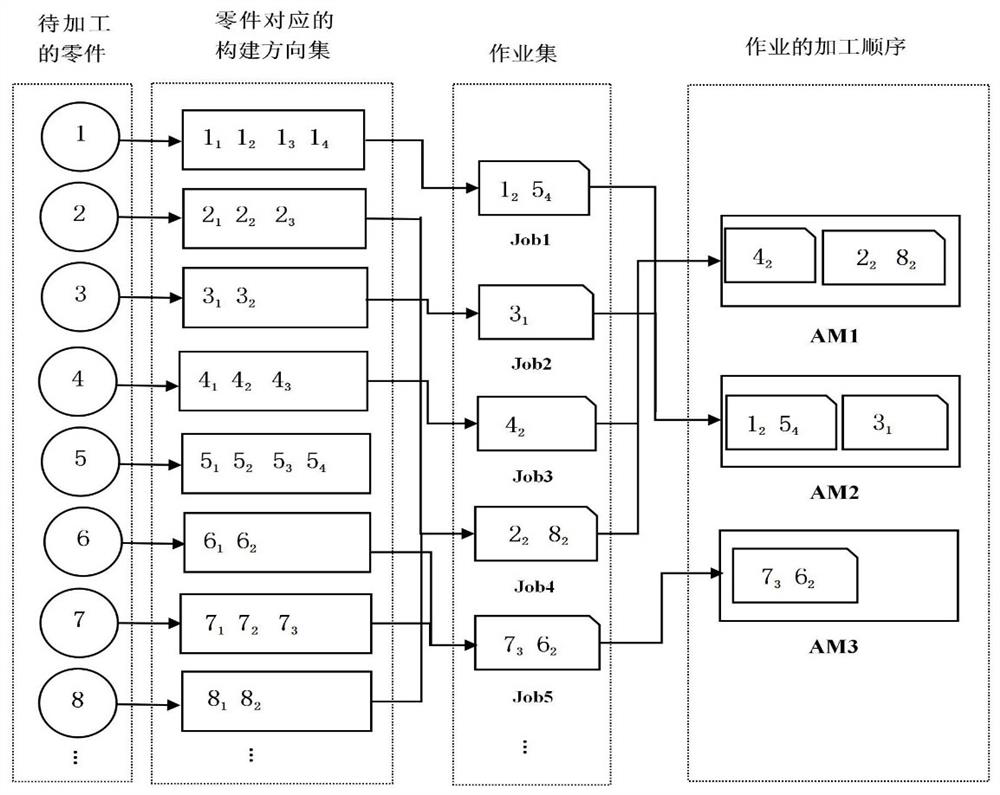

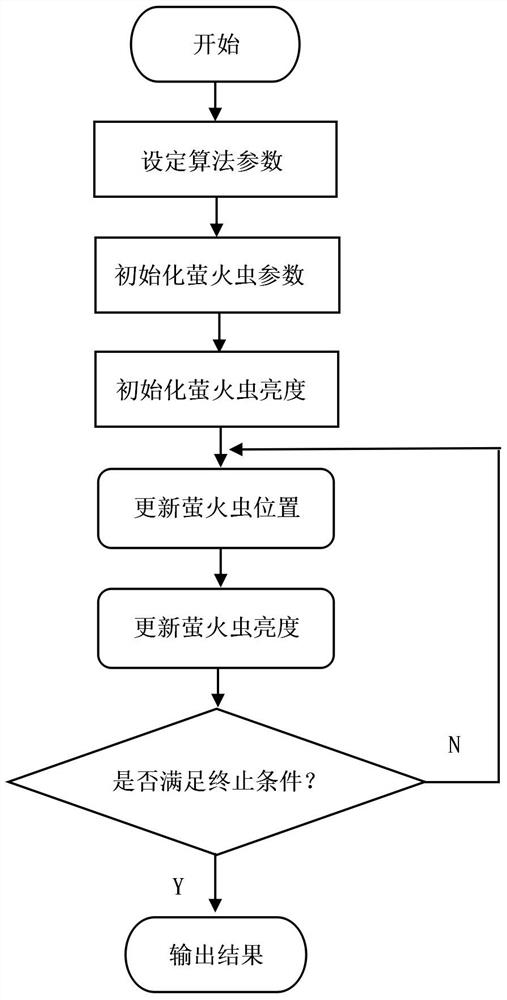

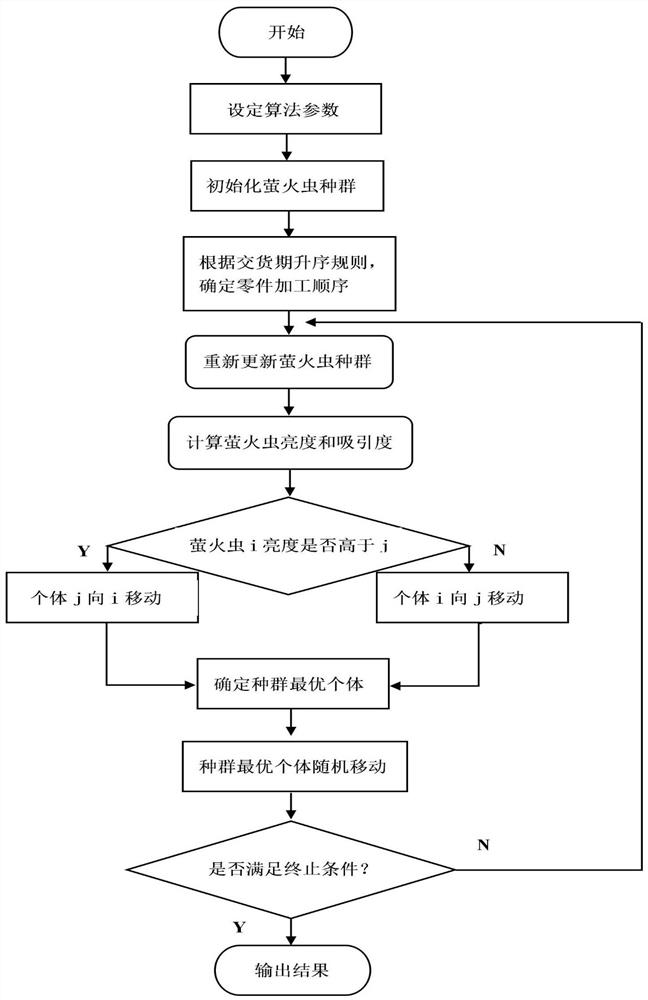

Method used

Image

Examples

Embodiment 1

[0138] A part set with 10 parts and three AM machines with the same processing parameters and performances were selected to carry out the research experiment, in which the construction direction, volume, delivery date and projected area data of the parts are shown in Table 1; The processing parameters are shown in Table 2.

[0139] Table 1 Data of parts to be processed

[0140]

[0141]

[0142] Table 2 AM machine processing parameters

[0143]

[0144] Table 3 Performance comparison of FA and IFA

[0145]

[0146] The improved firefly algorithm is compared with the basic firefly algorithm, and the simulation experiment is carried out by Matlab R2018b programming tool. The number of individuals in the firefly population is 200, and the maximum number of iterations MaxG is 300; in the algorithm, the maximum attractiveness β 0 is 1, the initial step size α 0 is 1, and the light intensity absorption coefficient γ is 0.5. In order to eliminate the influence of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com