A spent fuel storage grid square tube welding tool

A storage grid, welding tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficulty in controlling the manufacturing accuracy of the pan-fuel storage grid square tube, difficult to control the positioning accuracy and welding deformation, etc. , to achieve precise dimensions and shape tolerances, ensure cylindricity, and meet the needs of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

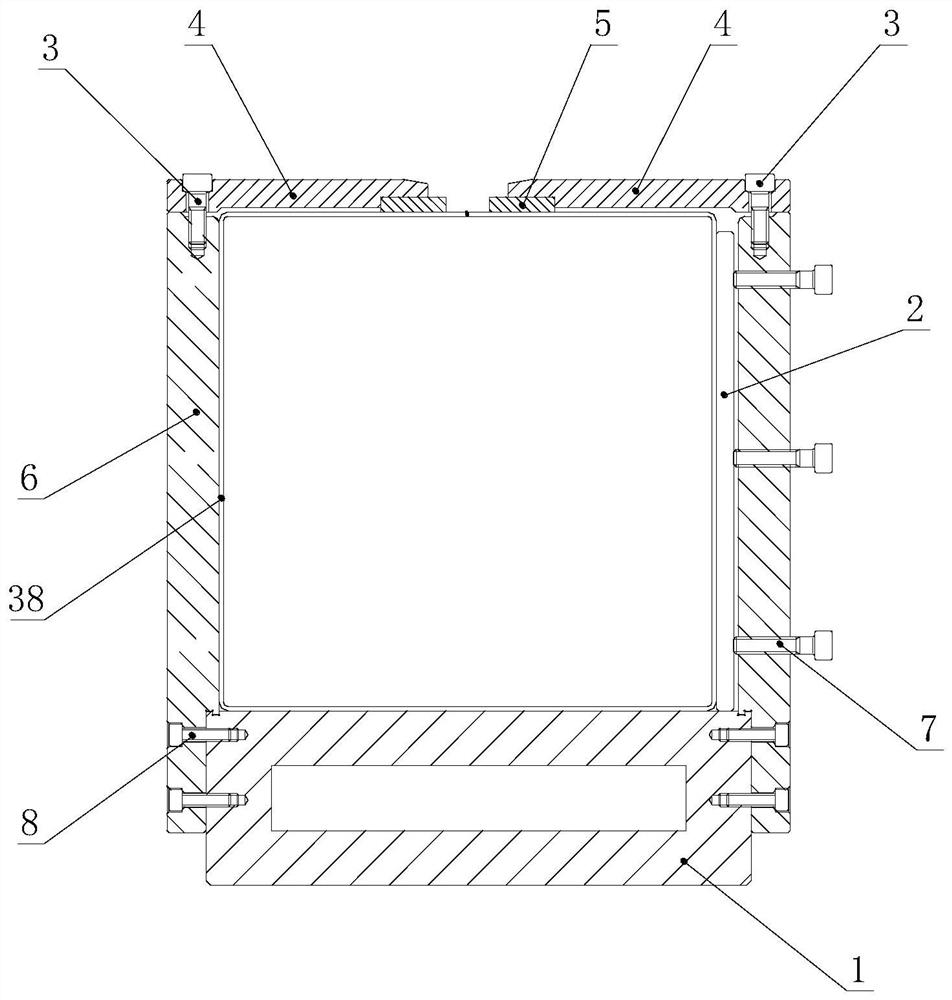

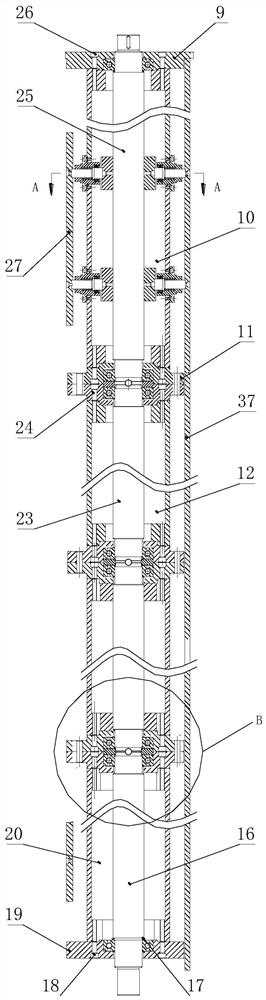

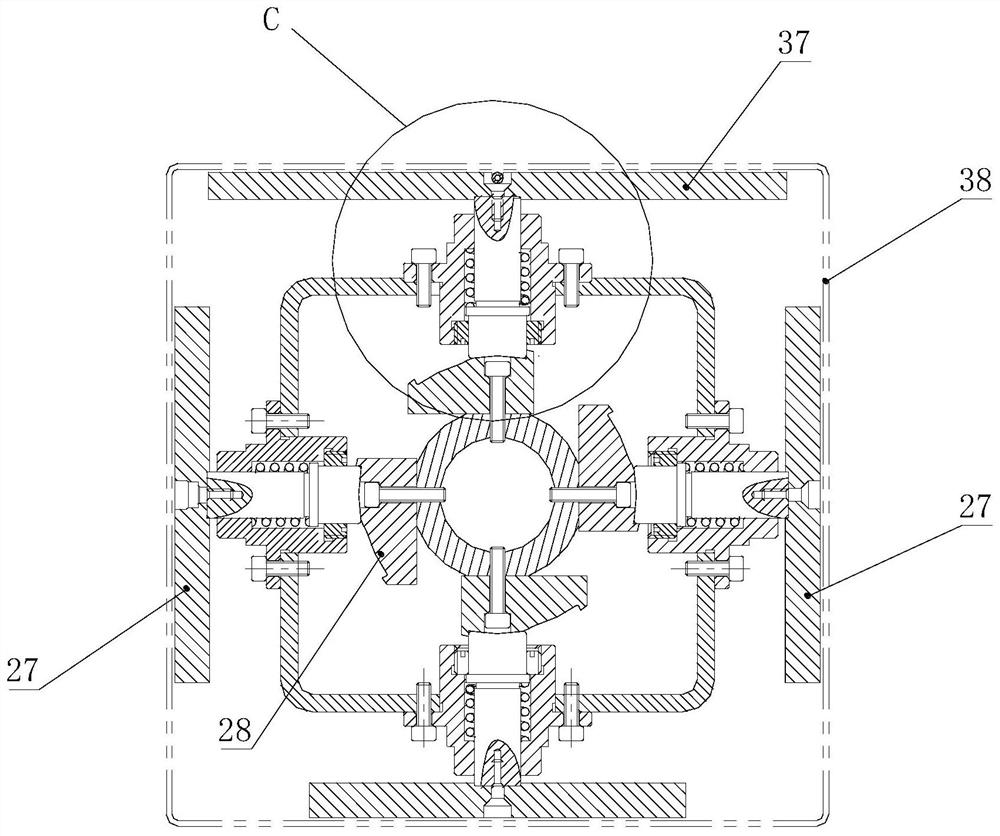

[0032] A spent fuel storage grid square tube 38 welding tool, including an outer clamping mechanism and an inner lining mechanism; the outer clamping mechanism includes a clamping seat provided with a fixing groove, and the opening of the fixing groove is detachably connected with a pressure plate 4, The cavity surrounded by the fixed groove and the pressing plate 4 is used to accommodate the square pipe 38; the lining mechanism includes three short backing plates 27, a long backing plate 37 and a drive mandrel, and the short backing plates 27 and The long backing plate 37 is evenly distributed along the circumferential direction of the drive mandrel, and the long backing plate 37 is driven to extend along the length direction of the mandrel, and the short backing plate 27 is provided with several pieces along the length direction of the drive mandrel; the circumference of the drive mandrel is evenly distributed There are four drive assemblies for driving the backing plate to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com