A vibration-damping clamping tool for large thin-walled parts

A technology for large thin-walled parts and thin-walled workpieces, which is applied in the field of large-scale thin-walled parts vibration damping and clamping tooling, can solve the problems of inconvenient installation and disassembly, low positioning accuracy, and poor clamping quality, and achieves easy installation and strong adaptability. , Good vibration damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

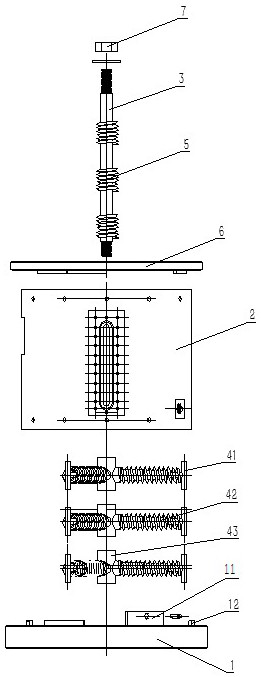

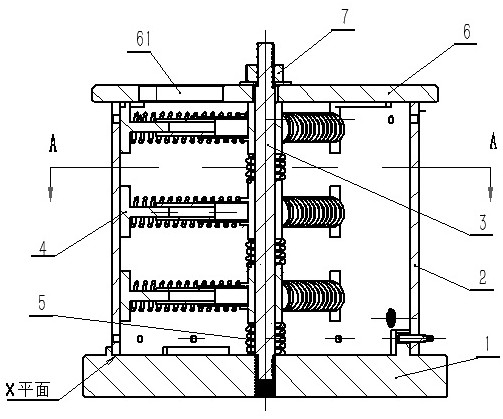

[0020] Example 1, such as figure 1 and figure 2 As shown, the present invention provides a vibration damping and clamping tool for large thin-walled parts, including a positioning substrate 1, a thin-walled workpiece 2 is arranged on the positioning substrate 1, and a pressing assembly is arranged on the upper part of the thin-walled workpiece 2, namely The thin-walled workpiece 2 is clamped between the positioning base plate 1 and the pressing assembly. The inside of the thin-walled workpiece 2 is provided with a main tie rod 3 in the axial direction, preferably the main tie rod 3 is arranged along the axis of the thin-walled workpiece 2, and the two ends of the main tie rod 3 are fixedly connected with the positioning substrate 1 and the pressing assembly respectively, so as to realize the alignment of the thin-walled workpiece 2. Axial positioning of workpiece 2. Several groups of tensioning components 4 are arranged on the main tie rod 3, and the tensioning components 4...

Embodiment 2

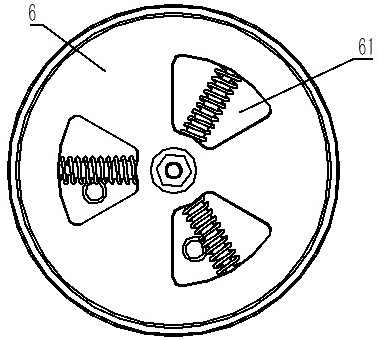

[0026] Example 2, such as image 3 As shown, a large-scale thin-walled vibration damping and clamping tool, the positioning platen 6 is provided with a through hole 61, in this embodiment, the through hole 61 is a fan-shaped structure, and along the central axis of the positioning platen 6 There are 3 evenly set. The functions of the three through holes are as follows: first, it is used to reduce the weight of the entire tooling, which is beneficial to disassembly, movement, and hoisting of large thin-walled workpieces; second, it is beneficial to cutting fluid processing Inner cavity; thirdly, it is convenient to observe the use state of the tensioning component, so as to prevent abnormal phenomena and damage to thin-walled workpieces.

[0027] Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com