Machining and conveying method for bearing bush of marine diesel engine

A technology of marine diesel engine and conveying direction, applied in the direction of mechanical conveyor, conveyor, connecting rod bearing, etc., can solve the problems of poor transmission line, large deformation, easy to loosen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

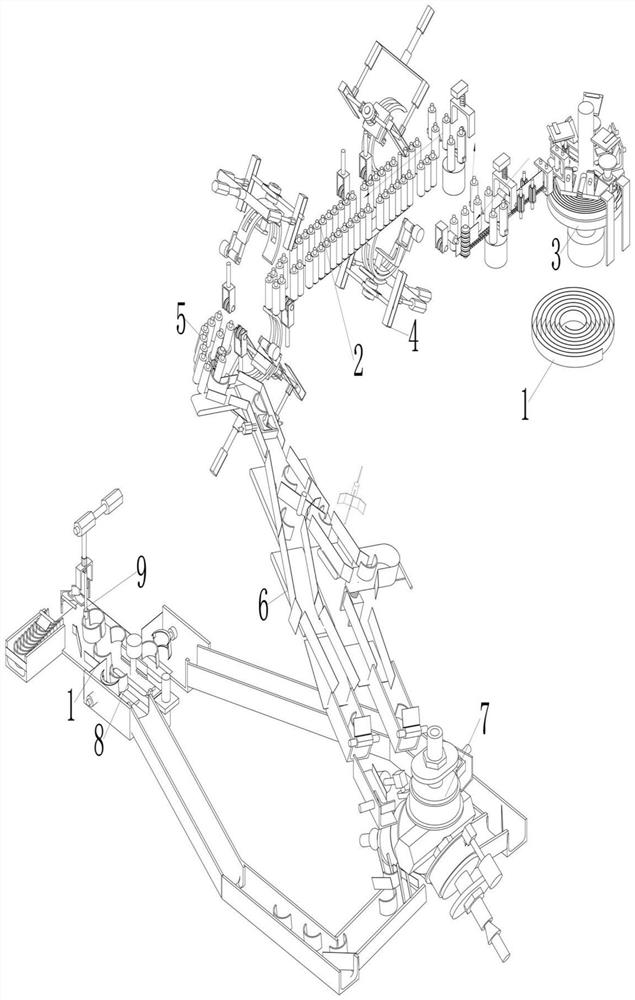

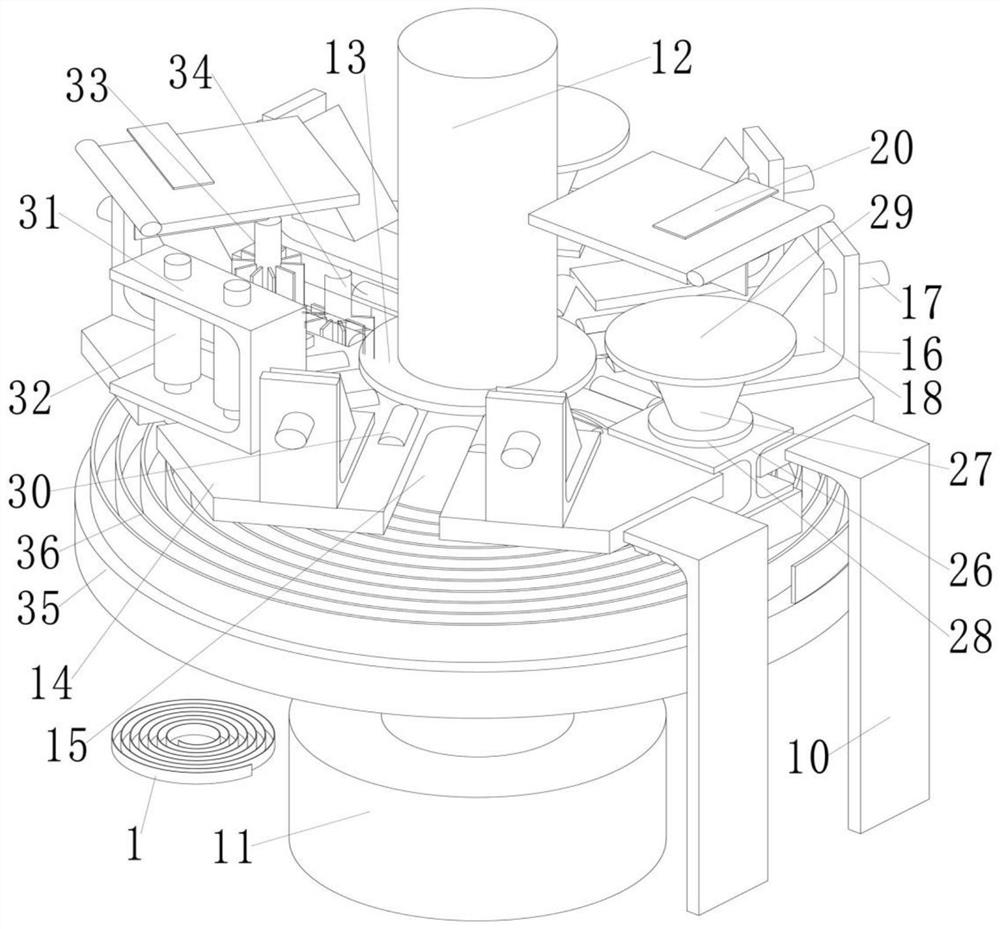

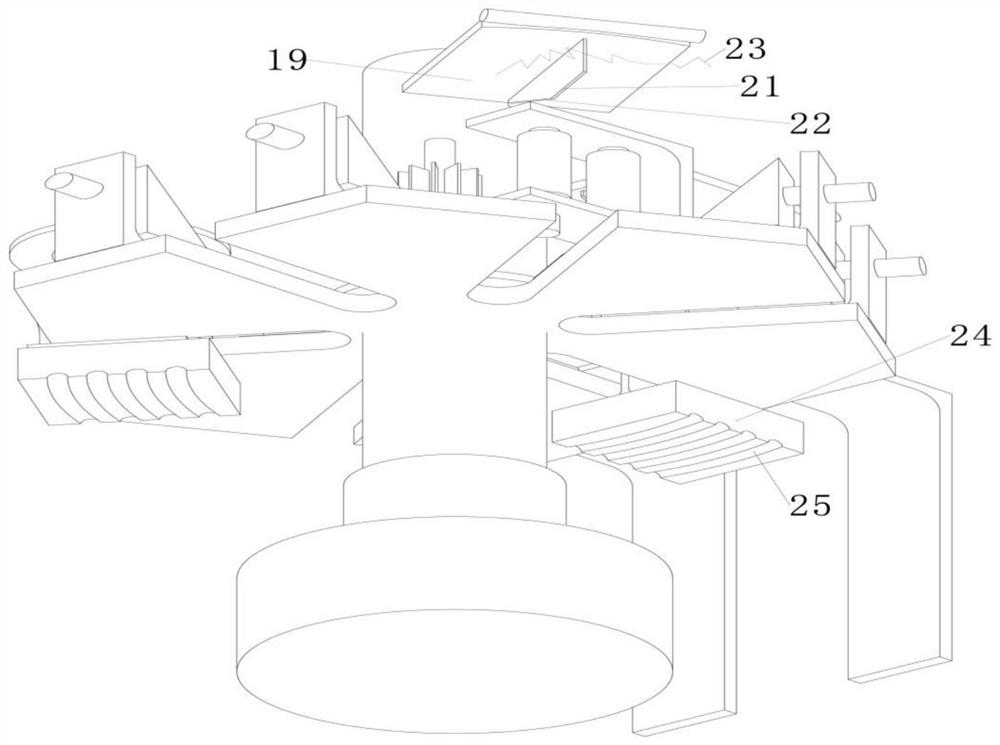

[0006] Such as Figure 1-15As shown, the large-diameter bearing bush intelligent processing line of this embodiment is used to process the bearing bush piece 1; it includes a transmission component 2; Matching station 6, processing outer circle component 7, processing inner hole component 8 and processing lip component 9. The feeding device 3 includes a feeding frame 10; a feeding rotating base 11 is arranged on the feeding frame 10, and a feeding central shaft 12 is rotated on the feeding rotating base 11, which is used for coiled bearing bushes. The hollow center sleeve set of part 1 is provided with a feeding center step 13 on the feeding center axis 12, which is used to contact the lower surface of the hollow center sleeve, and a feeding bottom bracket 14 is arranged on the feeding center step 13; On the loading bottom bracket 14, there is a radial groove 15 for loading bottom bracket radially; on the radial groove 15 of the loading bottom bracket, there is a feeding I-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com