High-toughness geopolymer grouting material modified by ultra-high molecular weight fiber-emulsified asphalt, its preparation method and application

A geopolymer and ultra-high molecular weight technology, used in cement production and other directions, can solve the problems of poor road substrate matching and durability, achieve low temperature sensitivity, improve matching, and prevent the entry of harmful impurities and water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

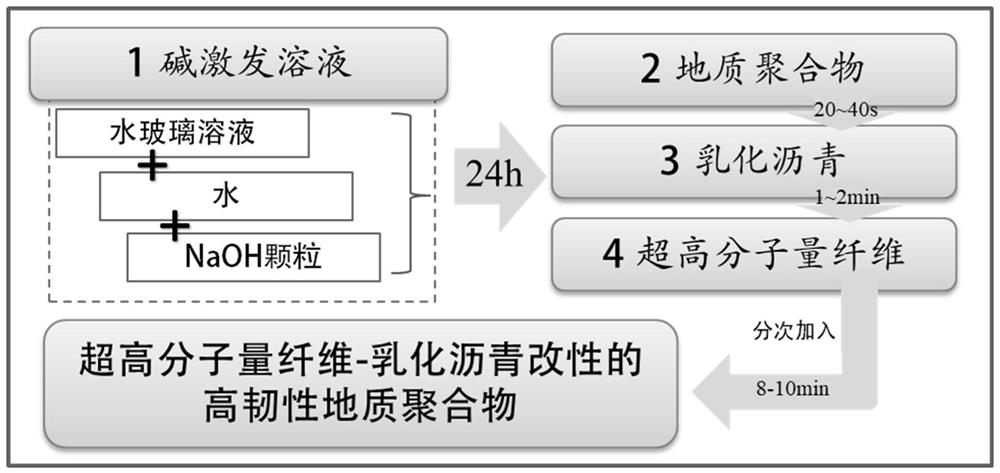

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a high-toughness geopolymer modified by ultra-high molecular weight fiber-emulsified asphalt. The mass components of this material are:

[0066] Emulsified asphalt: 8 parts

[0067] Geopolymer: 100 parts

[0068] Alkali challenge solution: 120 parts

[0069] Ultra High Molecular Weight Fiber: 2 parts.

[0070] In this implementation, the emulsified asphalt is medium-cracked or slow-cracked cationic emulsified asphalt, the sieve allowance of the cationic emulsified asphalt is ≤0.1%, and the 1d normal temperature stability is ≤1%.

[0071] In this implementation, the geopolymer is metakaolin with a bulk density of 1.25-1.72g / cm 3 .

[0072] In this implementation, the ultra-high molecular weight fiber density is 0.97g / cm 3 , the strain at break is 2 to 3%, the fiber diameter is 20 μm, the length is 6 mm, and the fiber volume dosage is 1%.

[0073] In this implementation, alkali excitation solution is made up of sodium silicate solution (wat...

Embodiment 2

[0089] This embodiment provides a high-toughness geopolymer modified by ultra-high molecular weight fiber-emulsified asphalt. The mass components of this material are:

[0090] Emulsified asphalt: 8 parts

[0091] Geopolymer: 100 parts

[0092] Alkali challenge solution: 90 parts

[0093] Ultra High Molecular Weight Fiber: 2 parts.

[0094] The kind and consumption of each raw material and performance requirement are identical with embodiment 1 in the present embodiment.

[0095] The preparation method and performance test of the high-toughness cement grouting material in this embodiment are basically the same as those in Embodiment 1.

[0096] In this example, the pumpability of the ultra-high molecular weight fiber-emulsified asphalt modified high-toughness geopolymer grouting material is analyzed more accurately to verify its feasibility as a grouting material. The thixotropic index of freshly prepared slurries was determined.

[0097] according to Figure 4 , prepared...

Embodiment 3

[0100] This embodiment provides a high-toughness geopolymer modified by ultra-high molecular weight fiber-emulsified asphalt. The mass components of this material are:

[0101] Emulsified asphalt: 8 parts

[0102] Geopolymer: 100 parts

[0103] Alkali challenge solution: 90 parts

[0104] Ultra High Molecular Weight Fiber: 2 parts.

[0105] The kind and consumption of each raw material and performance requirement are identical with embodiment 1 in the present embodiment.

[0106] The preparation method of the ultra-high molecular weight fiber-emulsified asphalt modified high-toughness geopolymer of this embodiment is basically the same as that of Embodiment 1.

[0107] In this example, in order to more accurately verify the performance evolution of the ultra-high molecular weight fiber-emulsified asphalt modified high-toughness geopolymer injected into the bottom of the cement concrete pavement slab, the structural recovery ability of the prepared fresh slurry was measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap