A kind of preparation method and application of ultrafine uniform acrylamide polymer hydrogel silk

An acrylamide copolymer and acrylamide copolymerization technology, applied in the medical field, can solve problems such as difficulty, small breaking force value, and difficult wire drawing processing, so as to reduce the number of uses, reduce the occupying effect, reduce the recurrence rate and relapse The effect of treatment rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

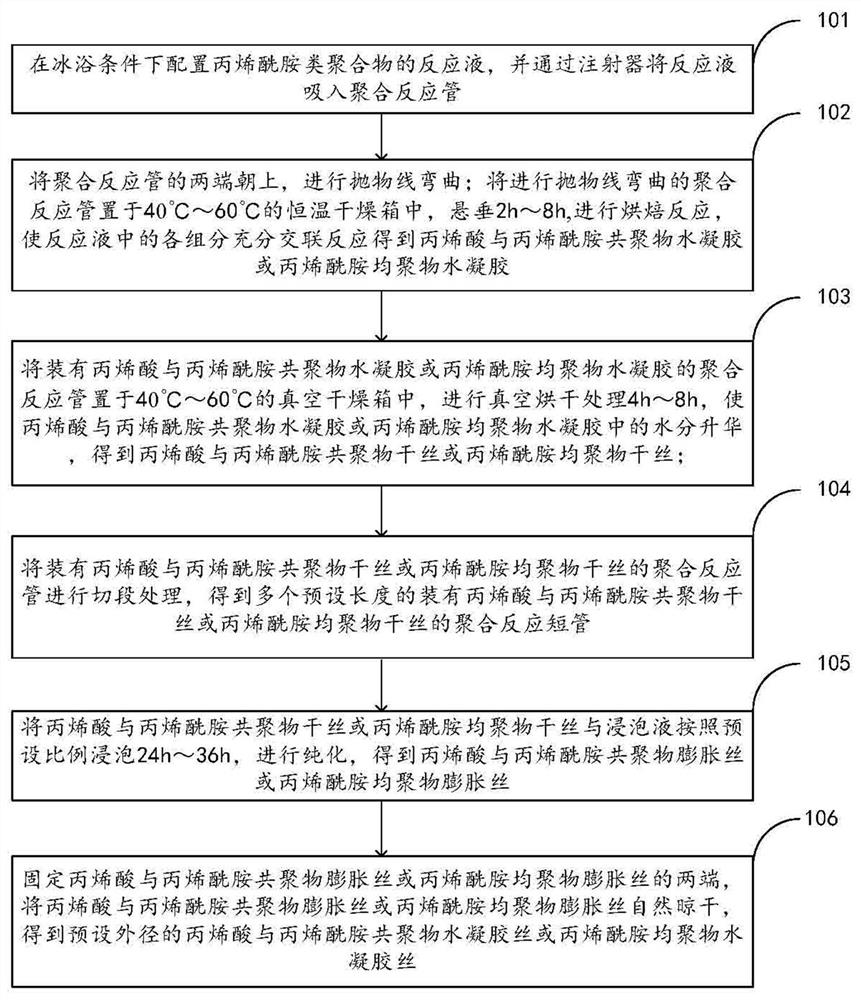

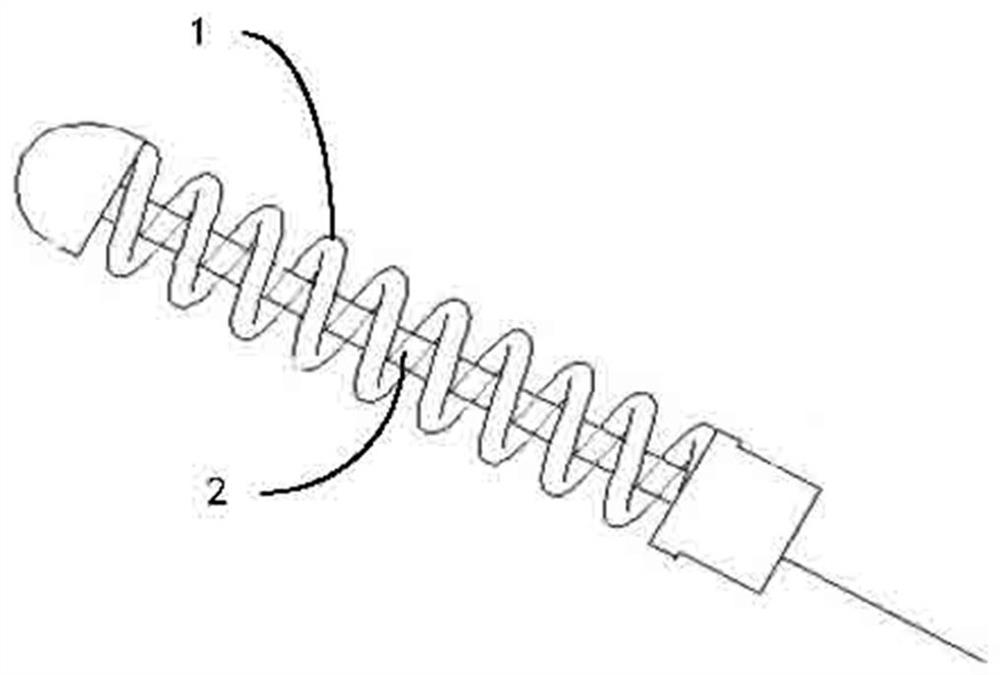

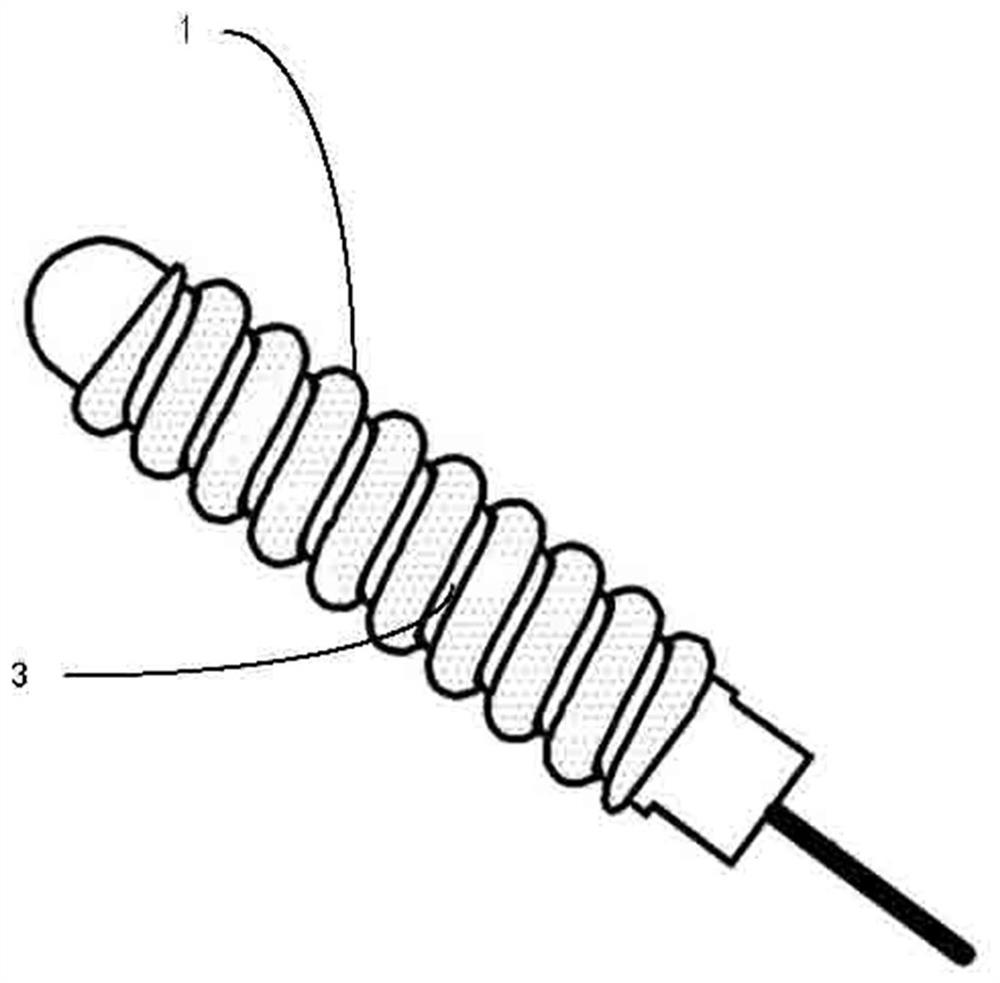

[0030] Embodiment 1 of the present invention provides a method for preparing ultra-fine and uniform acrylamide polymer hydrogel filaments. The reaction solution of acrylamide polymer is prepared under ice bath conditions, and sucked into the polymerization reaction tube. The parabolic suspension of the polymerization reaction tube is carried out in a constant temperature drying oven for baking reaction, so that the reaction solution is f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com