Hollow electroslag remelting consumable electrode as well as preparation method and electroslag remelting method thereof

A consumable electrode, electroslag remelting technology, applied in the field of electroslag metallurgy, can solve the problems of poor sealing performance of electroslag remelting furnace, uneven distribution of inert gas, rapid temperature drop of molten steel, etc. The effect of increasing inclusions and increasing gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

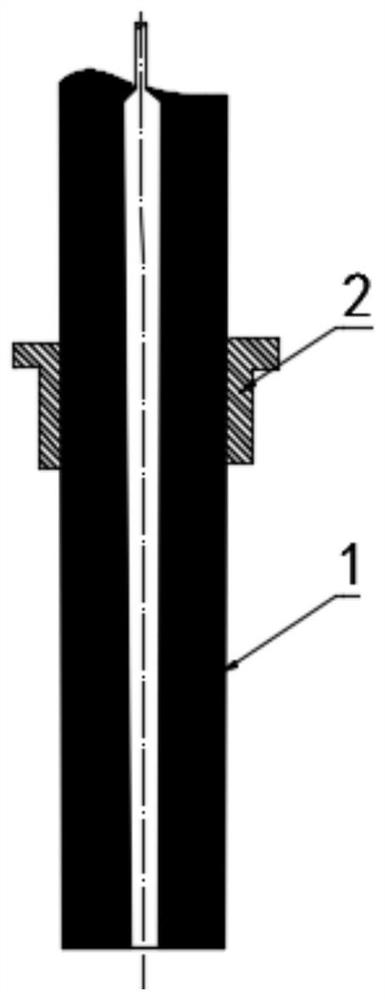

[0036] A method for preparing a hollow electroslag remelted consumable electrode, the steps are as follows:

[0037] 1) Configure the raw materials of the main body of the consumable electrode according to the types and contents of the elements required for the alloy ingot to be prepared corresponding to the consumable electrode and carry out alloying smelting. When the temperature of the molten steel reaches 1560-1580°C, the steel is tapped. The molten steel is poured to form a hollow electroslag remelting self-consumable electrode;

[0038] 2) Homogenize the consumable electrode poured in step 1) at 1200° C. for 9 hours to obtain the hollow electroslag remelted consumable electrode.

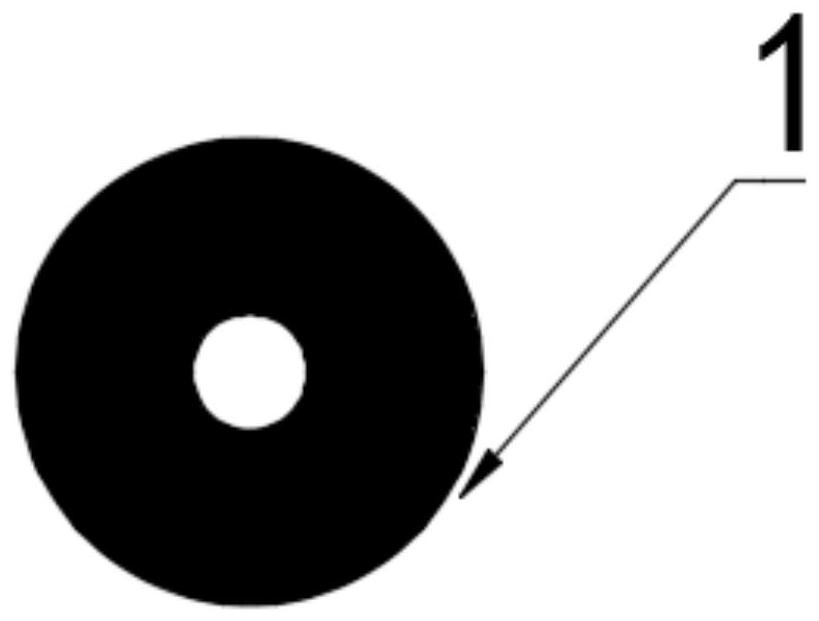

[0039] The diameter of the electroslag remelting consumable electrode prepared in this embodiment is 600 mm; the hollow hole diameter of the hollow rod body is 50 mm.

Embodiment 2-9

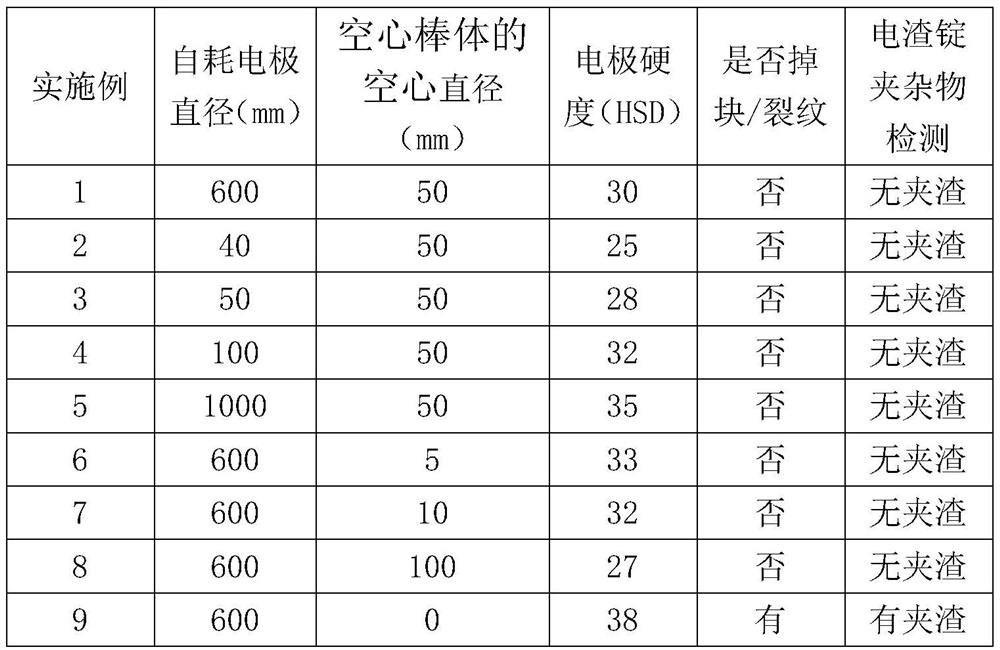

[0041] Embodiment 2-9 provides a method for preparing a hollow electroslag remelting consumable electrode. Compared with embodiment 1, the difference is that the diameter of the consumable electrode and the size of the hollow hole of the hollow rod are changed , except for the above differences, other operations are the same and will not be repeated here; the specific experimental conditions, parameters and test results are shown in the table below.

[0042]

[0043] It can be seen from the results in the above table that when the diameter of the consumable electrode made by pouring is 50-1000mm, the hardness of the prepared consumable electrode is 29-35HSD, which shows that the hollow electroslag remelted consumable electrode prepared by the present invention The electrode has higher hardness; and compared with the electroslag remelting consumable electrode without hollow structure prepared in Example 9, the consumable electrode prepared in the embodiment of the present inv...

Embodiment 10

[0045]In this embodiment, the GH37 alloy is used as the consumable electrode, the size of the consumable electrode blank is ∮500mm, and the mold size is ∮600mm.

[0046] Select remelting and refining slag of the following components by weight: CaF 2 50 parts, Al 2 o 3 20 parts, CaO 15 parts, TiO 2 10 parts and MgO 5 parts. Among them, CaF 2 、Al 2 o 3 , CaO, TiO 2 And the mass content of SiO2 in MgO is less than or equal to 1.0%.

[0047] The following method is used to carry out electroslag remelting of GH37 alloy, including the following steps:

[0048] S1. Heat and bake the above-mentioned remelting and refining slag at 800°C for 10 hours, use the above-mentioned GH37 alloy as the consumable electrode, assemble the electroslag remelting furnace, and slowly lower and insert the hollow electroslag remelting consumable electrode In the slag of the electroslag furnace, the deoxidizer and the remelted refining slag baked in step 1) are added to the special slag meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com