Evaporation crucible and evaporation device

A crucible and evaporation technology, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

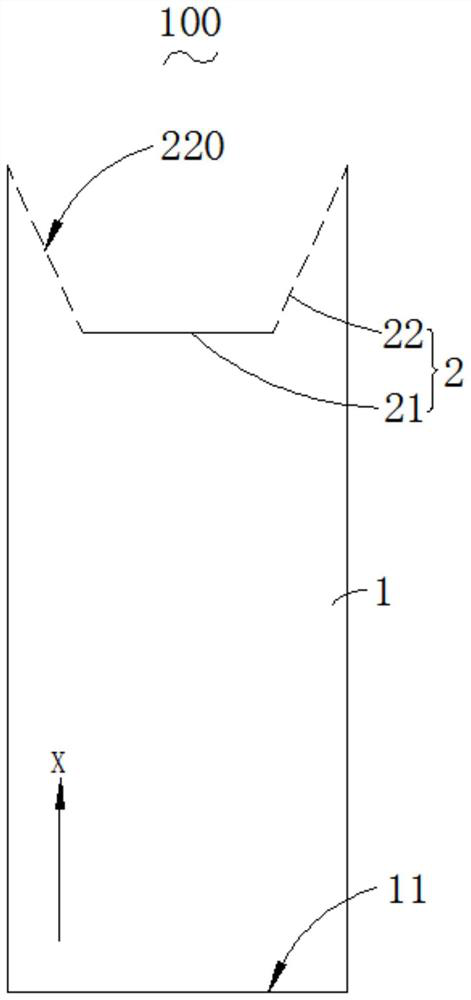

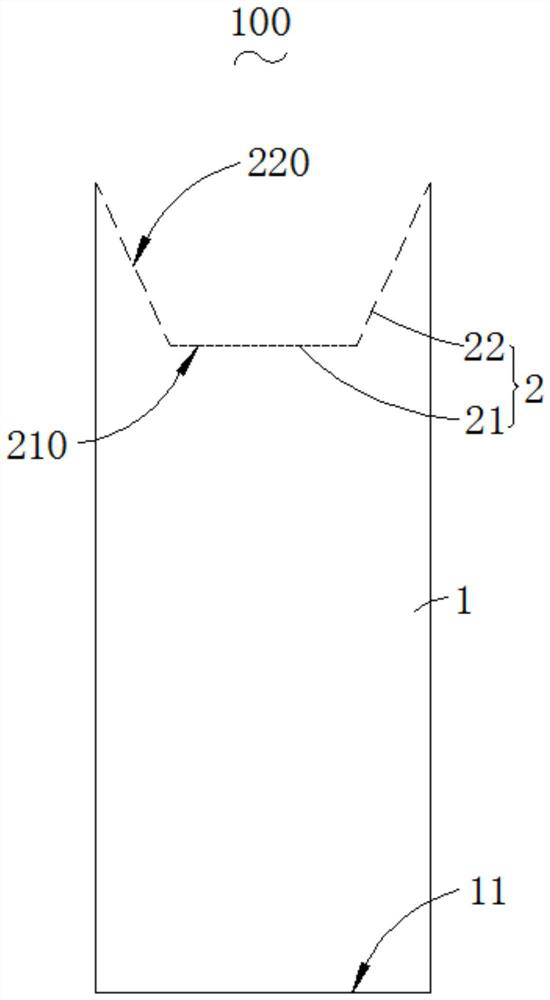

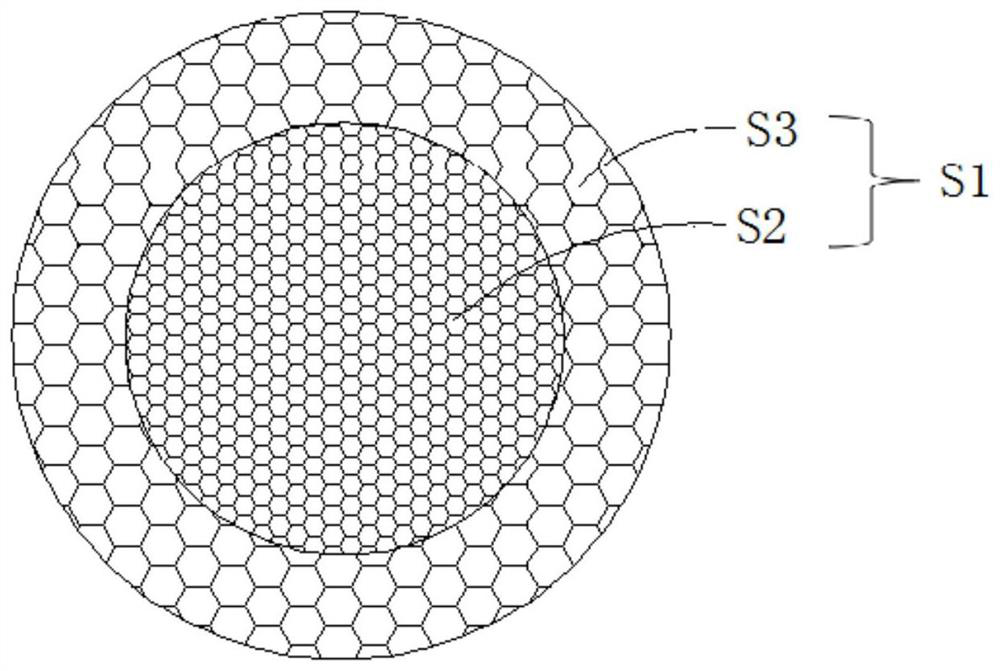

[0024] In the current preparation process of OLED devices, evaporation is usually used to prepare various film layers of OLED devices, but the problem of impurities clogging the evaporation crucible is prone to occur during the evaporation process. Taking the vapor-deposited film layer as the cathode as an example, the cathode film layer is mainly vapor-deposited ytterbium and magnesium / silver film layers. However, due to the material characteristics of magnesium and ytterbium, there is a layer of oxide on the surface of magnesium and ytterbium materials. During the evaporation process of magnesium and ytterbium materials, the oxides on the surface of magnesium and ytterbium materials fall off and form Ash (ash), which is easy to The overflow from the evaporation crucible leads to a sharp increase in the content of Particles in the evaporation chamber, which in turn leads to an increase in the amount of particles on the substrate surface, directly reducing the product yield.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com