Efficient drying and cleaning device for clothes

A drying device and high-efficiency technology, which can be used in the configuration of equipment for processing textile materials, the removal of liquid/gas/steam by centrifugal force, the treatment of liquid/gas/steam finished products, etc. It can solve the problem of working efficiency without cleaning function and increase the workload of staff Quantity, cumbersome processing of textiles and clothing, etc., to avoid time consumption, increase speed, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

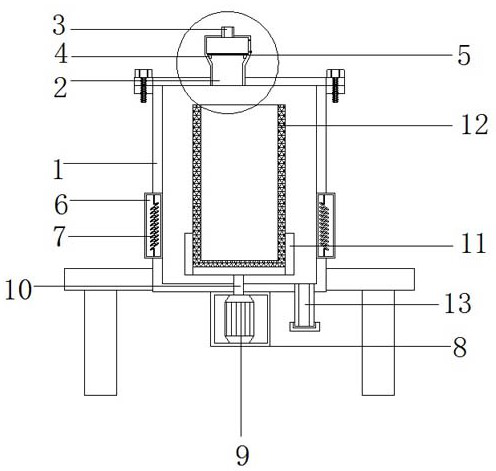

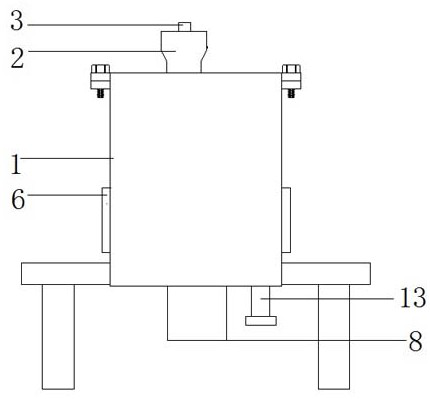

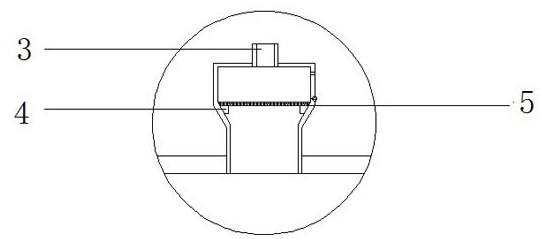

[0019] Embodiment 1, with reference to Figure 1-3 , a high-efficiency drying device for clothing cleaning, including a casing 1, a cleaning material box 2 is welded on the outer wall of the top of the casing 1, and a water inlet pipe 3 is welded on the outer wall of the top of the cleaning material box 2, and the top of the cleaning material box 2 There is a water inlet on the outer wall, and the size of the inner wall of the water inlet matches the size of the outer wall of the water inlet pipe 3. The outer wall of the top of the casing 1 is provided with a cover plate, and the cover plate is connected to the outer wall of the top of the casing 1 by bolts. The inner wall of the middle part of the cleaning material box 2 is welded with fixed blocks 4 equidistantly distributed, and the outer wall of the top of the fixed block 4 is fixed with a filter screen 5, and the outer walls of both sides of the lower part of the casing 1 are provided with symmetrically distributed heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com