Dynamic double-frequency ultrasonic cleaning and drying method and device

An ultrasonic and dynamic technology, applied in the field of aerospace, can solve the problems of not obvious effect, difficult removal of impurities, low cleaning efficiency, etc., to achieve the effect of completely removing impurities and carbon deposits, increasing efficiency, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

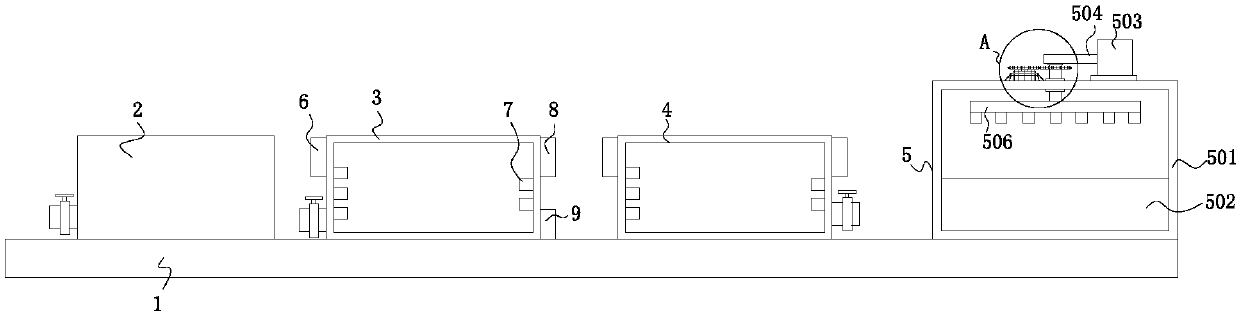

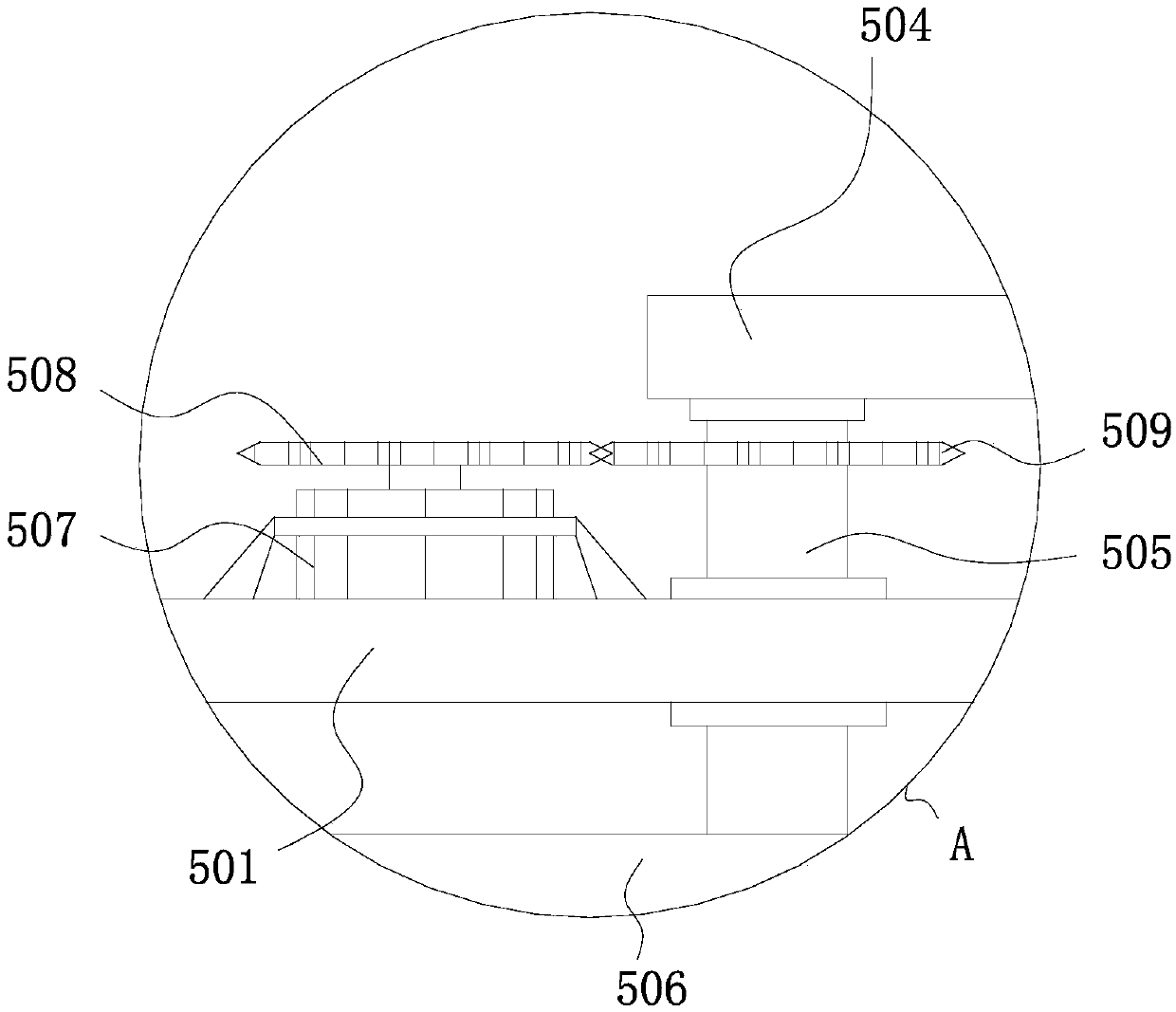

[0038] A dynamic dual-frequency ultrasonic cleaning and drying method, including the following equipment: soaking tank, ultrasonic dual-frequency cleaning tank, ultrasonic rinsing tank, circulation pump, dynamic circulation filter, nitrogen pressure water blowing, ultrasonic system, circulation filtration system and heating The system, soaking tank, ultrasonic dual-frequency cleaning tank and ultrasonic rinsing tank are all made of stainless steel, the number of equipment is one, and the number of equipment for circulation pump and dynamic circulation filter is two.

[0039] One side of the inner wall of the ultrasonic dual-frequency cleaning tank and the ultrasonic rinsing tank is fixedly installed with an inlet pipeline connected to the nozzle. The inlet pipeline is welded with five interfaces, and the material of the inlet pipeline is stainless steel pipe. A dynamic circulation filter is fixedly installed on the outer side of the tank.

[0040] The specific operation steps ...

Embodiment 2

[0054] A dynamic dual-frequency ultrasonic cleaning and drying method, including the following equipment: soaking tank, ultrasonic dual-frequency cleaning tank, ultrasonic rinsing tank, circulation pump, dynamic circulation filter, nitrogen pressure water blowing, ultrasonic system, circulation filtration system and heating The system, soaking tank, ultrasonic dual-frequency cleaning tank and ultrasonic rinsing tank are all made of stainless steel, the number of equipment is one, and the number of equipment for circulation pump and dynamic circulation filter is two.

[0055] One side of the inner wall of the ultrasonic dual-frequency cleaning tank and the ultrasonic rinsing tank is fixedly installed with an inlet pipeline connected to the nozzle. The inlet pipeline is welded with five interfaces, and the material of the inlet pipeline is stainless steel pipe. A dynamic circulation filter is fixedly installed on the outer side of the tank.

[0056] The specific operation steps ...

Embodiment 3

[0070] A dynamic dual-frequency ultrasonic cleaning and drying method, including the following equipment: soaking tank, ultrasonic dual-frequency cleaning tank, ultrasonic rinsing tank, circulation pump, dynamic circulation filter, nitrogen pressure water blowing, ultrasonic system, circulation filtration system and heating The system, soaking tank, ultrasonic dual-frequency cleaning tank and ultrasonic rinsing tank are all made of stainless steel, the number of equipment is one, and the number of equipment for circulation pump and dynamic circulation filter is two.

[0071] One side of the inner wall of the ultrasonic dual-frequency cleaning tank and the ultrasonic rinsing tank is fixedly installed with an inlet pipeline connected to the nozzle. The inlet pipeline is welded with five interfaces, and the material of the inlet pipeline is stainless steel pipe. A dynamic circulation filter is fixedly installed on the outer side of the tank.

[0072] The specific operation steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com