Plunger type valve

A plunger type and plunger technology, which is applied in the field of material conveying control valves, achieves the effects of convenient operation, improved wear resistance, and high material control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Note that the present invention is not limited to the embodiments to be described below.

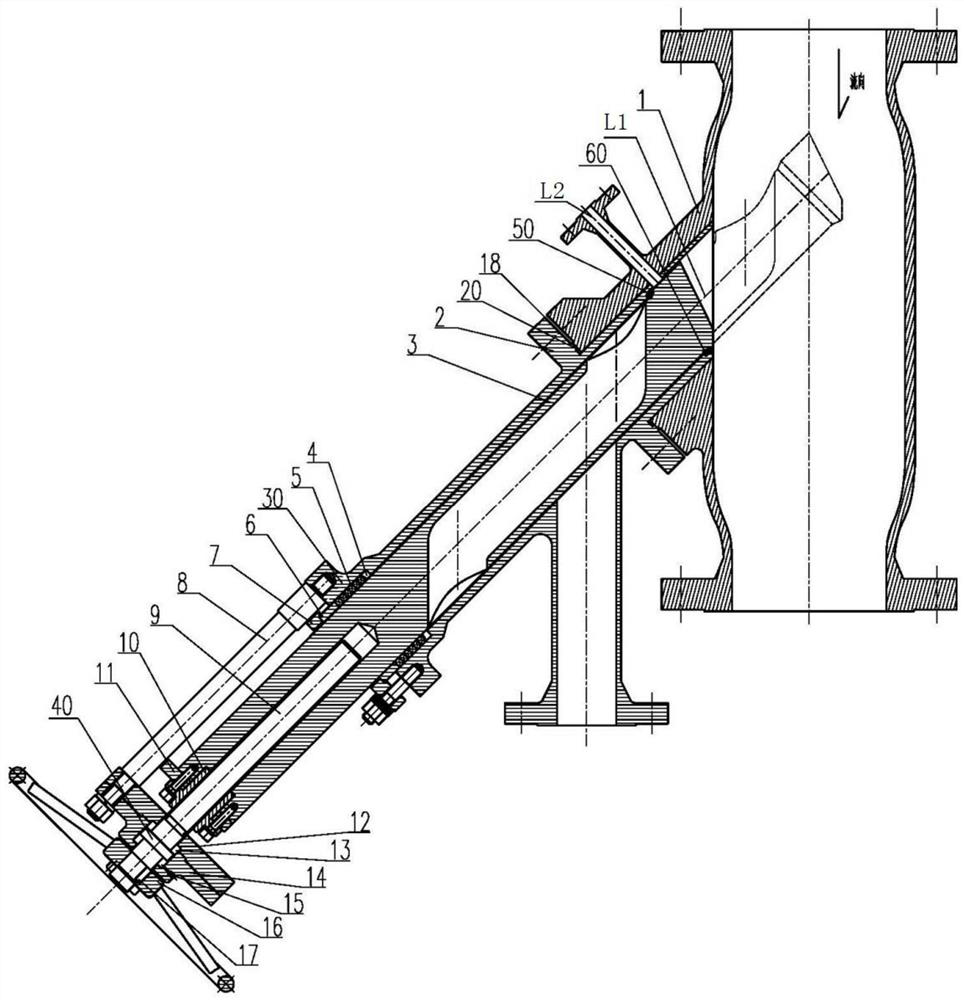

[0018] Such as figure 1 As shown, the plunger valve includes a main pipe platform 1, a valve body assembly 2, a plunger assembly, and a support assembly.

[0019] The main platform 1 is a pipeline with a special boss. A purge port and a purge device (not shown in the figure) are provided on the main pipe platform 1 . The purge flange of the plunger valve is located on the main pipe platform 1 and communicates with the main pipe platform 1 . In addition, the angle between the central axis L2 of the above-mentioned purge port and the central axis L1 of the valve body assembly 2 ranges from 45° to 135° near the sealing surface of the plunger, so that the seal can be effectively blown off when the valve is opened and closed. The medium at the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com