Semiconductor refrigeration and heating cycle box structure and manufacturing method thereof

A technology of cooling and heating, box structure, applied in the direction of refrigerator, refrigeration and liquefaction, machine operation mode, etc., can solve the problems of inability to accurately control the size of the plug card, different sizes, affecting the local fluid flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

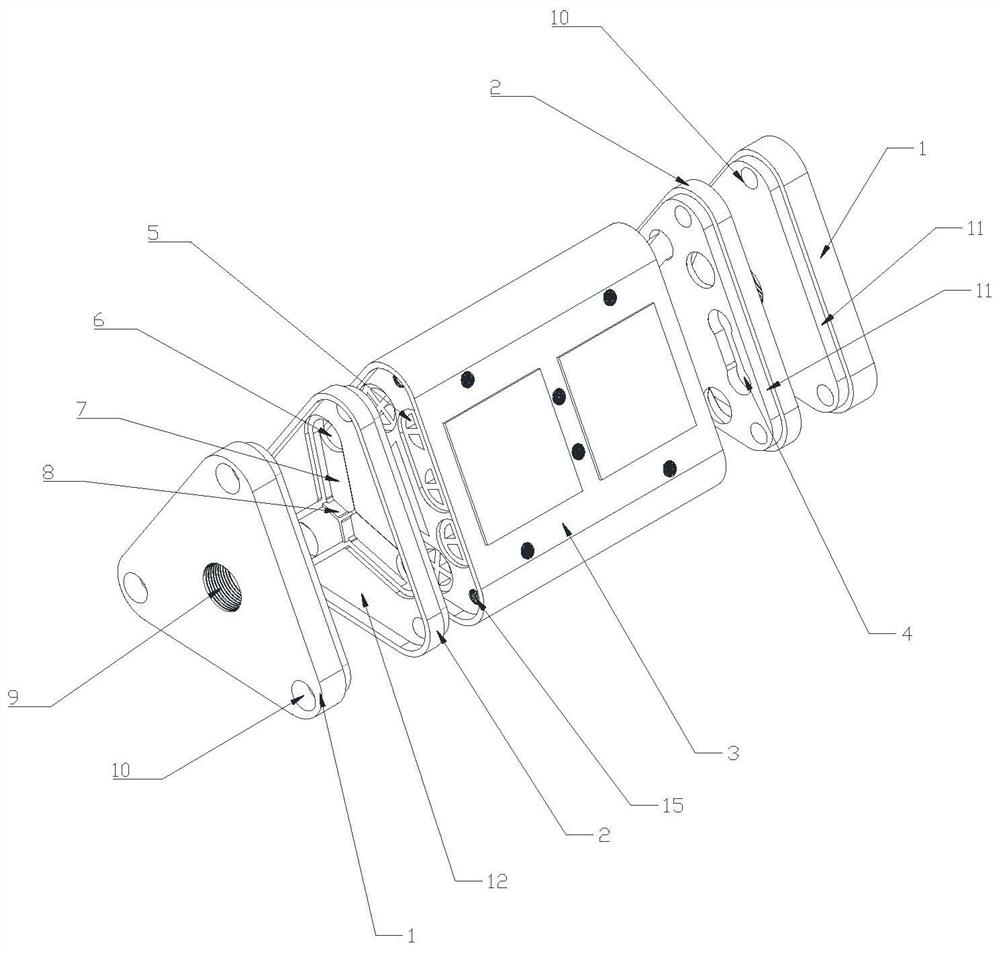

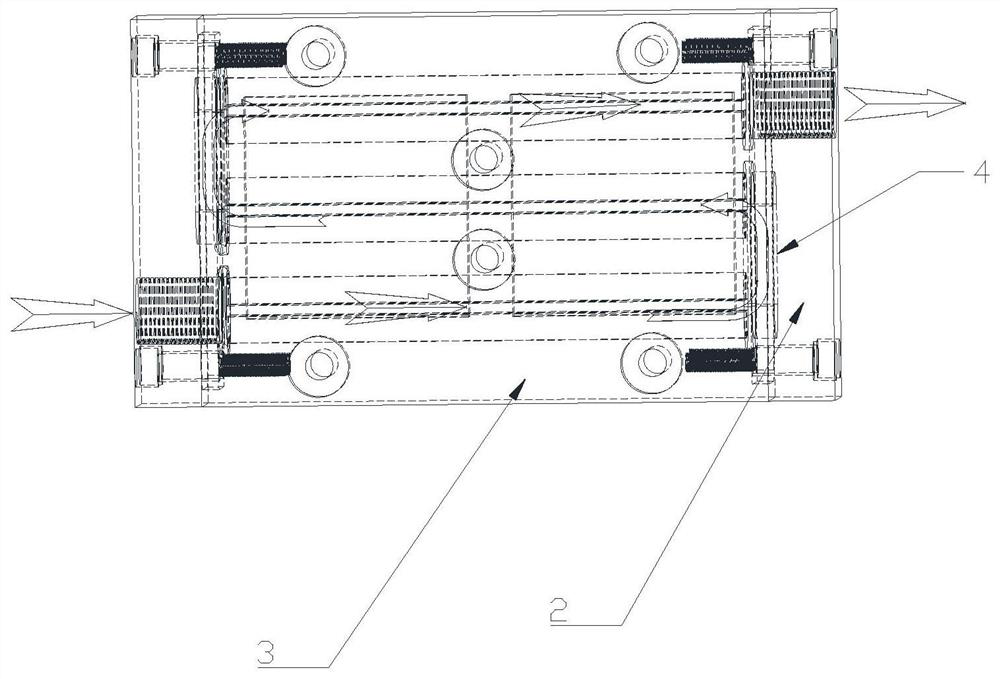

[0022] Embodiment 1: as Figure 1-2 As shown, the present invention and a semiconductor refrigeration and heating cycle box structure include a box body 3, an inner cover 2 and an outer cover 1, wherein the box body, the inner cover and the outer cover are made of metal materials with good thermal conductivity, and the inner cover and the outer cover are triangular, and the box body is in the shape of a triangular prism. Three groups of flow guide units are arranged in the box, and they are distributed in an equilateral triangle. Three straight holes 5 are arranged in the body of the flow guide unit; A plurality of secondary small holes evenly distributed in the circumferential direction are set, and the cross section of a single small hole is fan-shaped; the inner cover 2 is fixed on the front and rear ends of the box body 3, and the outer cover is fixed on the outer end of the inner cover; the inner cover A shunt structure is arranged on the side adjacent to the outer cover,...

Embodiment 2

[0029] Embodiment 2: A method for manufacturing a semiconductor refrigeration and heating cycle box structure, comprising the following steps:

[0030] a. Make the box: three sets of fluid unit bodies are made of metal materials with good thermal conductivity. The box is in the shape of a triangular prism, and the three sets of guide fluid units in the box are distributed in a triangle. Among them, there are multiple sub-units in the flow guide unit. Small holes evenly distributed in the circumferential direction; the cross section of a single small hole is fan-shaped;

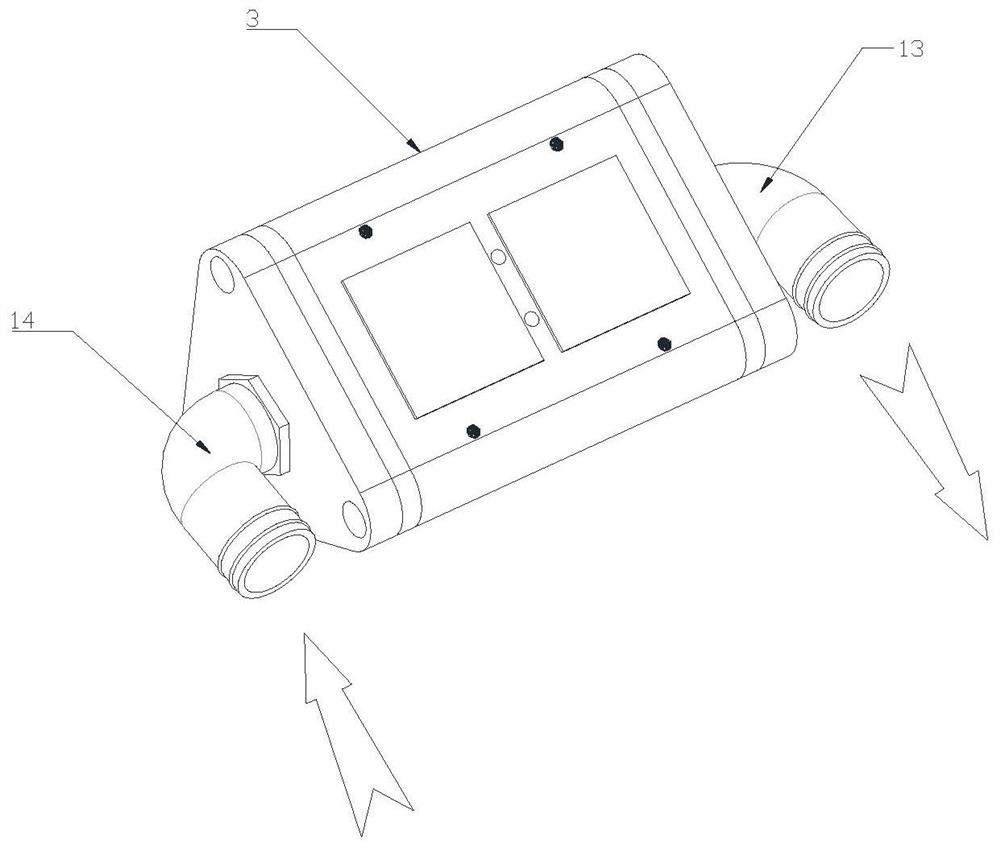

[0031] b. Making the inner cover: At the front and rear ends of the box, the inner cover is made of a metal material with good heat conduction, and a notch is provided on the side where the inner cover contacts the end surface of the box, and a shunt structure is set on the outside of the inner cover. The shunt structure is Semi-open structure, wherein the shunt structure includes a confluence section and thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com