Gas circuit assembly and gas pressure calibrator

A gas pressure and calibrator technology, which is applied in fluid pressure control, fluid pressure measurement, and electric fluid pressure control. It can solve problems such as poor adaptability, difficulty in replacement, and no vibration reduction system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The gas circuit assembly and the gas pressure calibrator of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

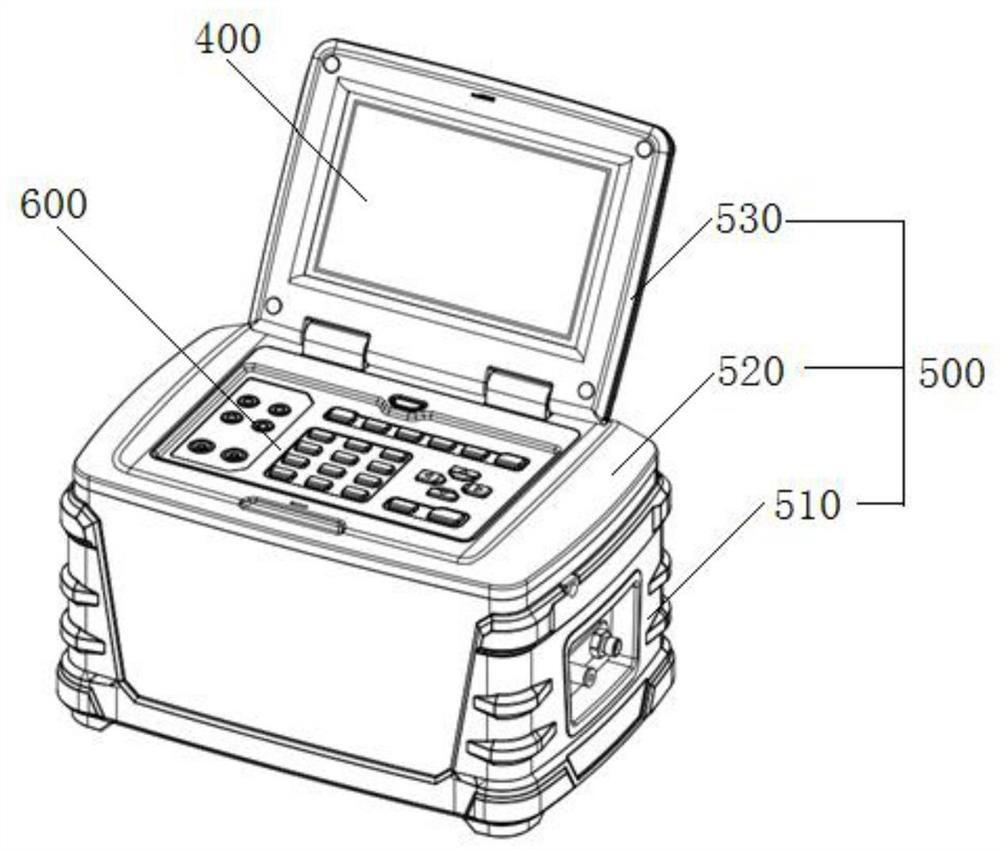

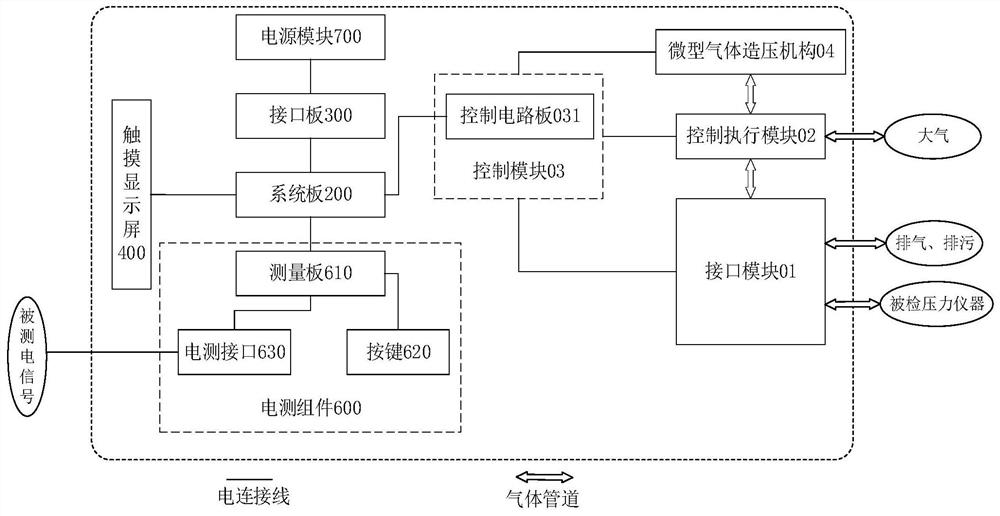

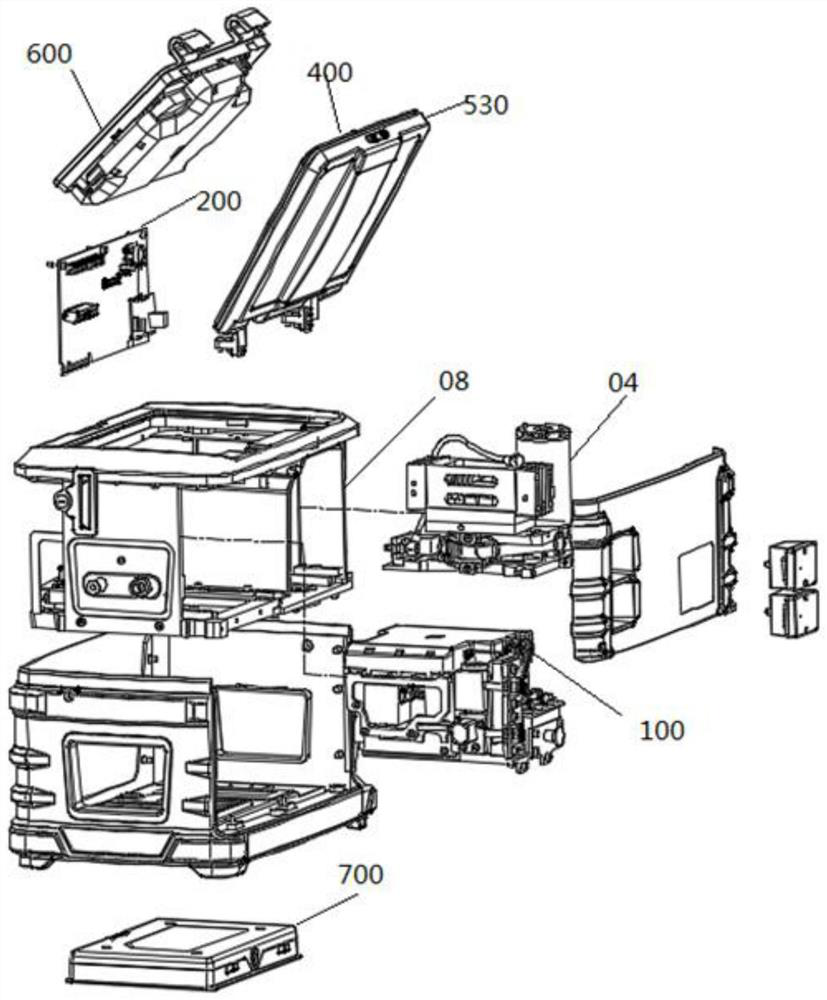

[0104] The gas pressure calibrator of the present invention adopts a modular design, combining Figure 1A to Figure 1D As shown, the calibrator includes a housing 500, a gas circuit assembly, a circuit component integrated in the housing, and a power module 700 installed outside the housing. Among them, the gas circuit components include the interface module 01, the control execution module 02 and the micro gas pressure making mechanism 04, and the circuit components include the touch screen 400, the system board 200, the interface board 300, the control circuit board 031 in the control module 03 and the electrical tester Component 600 , the electrical signal of the air circuit component is connected to the system board 200 through other circuit components. Each part is described in det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com