A temperature control system and control method for an aerosol generating device

A temperature control method and technology for generating devices, which are applied in the directions of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of reduced suction experience, low temperature control accuracy, and prone to burnt smell, etc., and achieve the goal of pumping Suction feels consistent and maintains a consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A temperature control system of an aerosol generating device, the temperature control system comprising:

[0030] Heating element, characteristic temperature control element of temperature coefficient of resistance, thermocouple temperature control element;

[0031] Both the characteristic temperature control element of the resistance temperature coefficient and the thermocouple temperature control element can independently measure the temperature of the heating element. The characteristic temperature control element of the temperature coefficient of resistance is integrated on the heating element.

Embodiment 2

[0033] A temperature control method for an aerosol generating device, the temperature control method comprising the following steps:

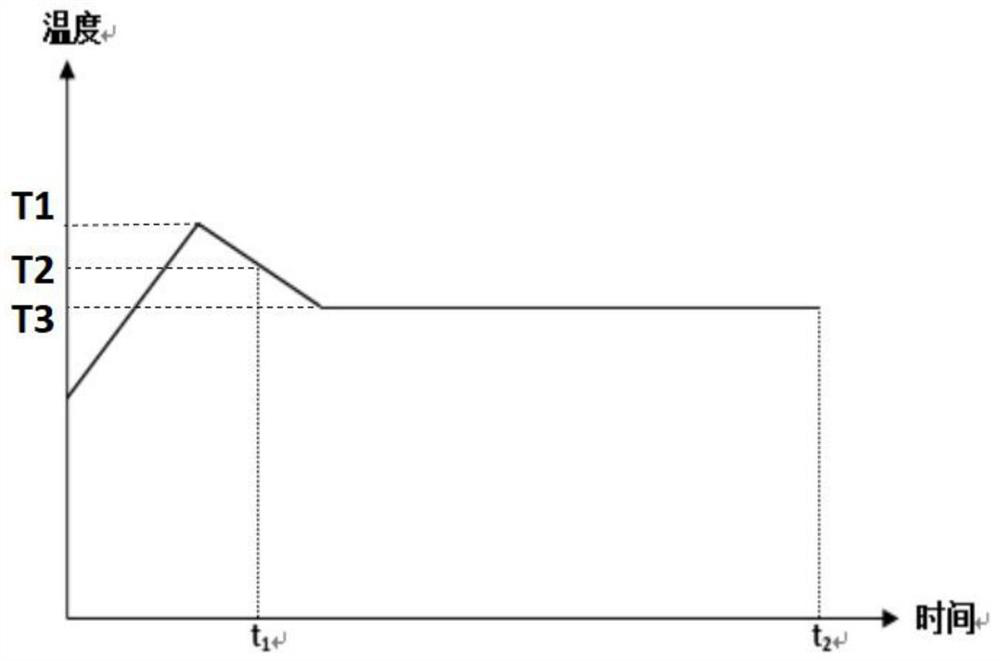

[0034] In the first stage 0 ~ t1 of the aerosol generating device, the heating temperature of the heating element is controlled from room temperature 25 degrees Celsius to T1 by using the temperature control method of the resistance temperature coefficient, and then cooled from T1 to T2; in the aerosol In the second stage t1-t2 of the generating device, the heating temperature of the heating element is controlled by the thermocouple temperature control method, and the temperature is lowered from T2 to T3, and it is kept stable; the heating temperature curve of the heating element is as follows: figure 1 shown.

[0035] T1 is 250 degrees Celsius, T2 is 200 degrees Celsius, and T3 is 160 degrees Celsius.

[0036] t1 is 20s, t2 is 100s, counting from the time when the aerosol generating device starts working.

[0037] The heating method of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com