Plasma etching equipment

A plasma and etching equipment technology, applied in the field of plasma etching equipment, can solve problems such as difficult to meet process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

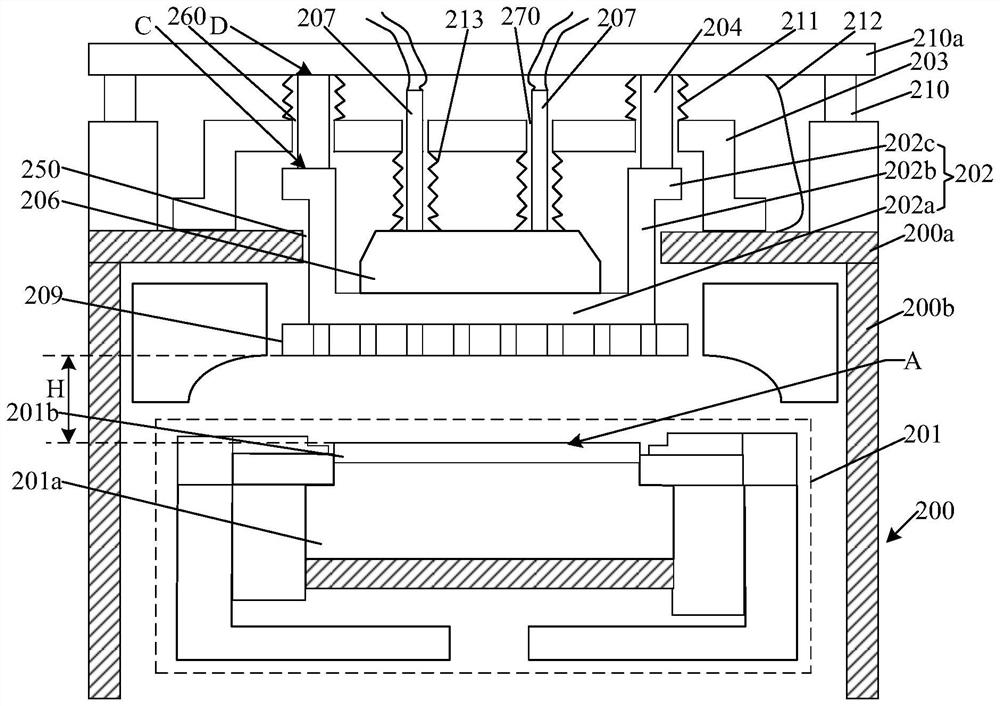

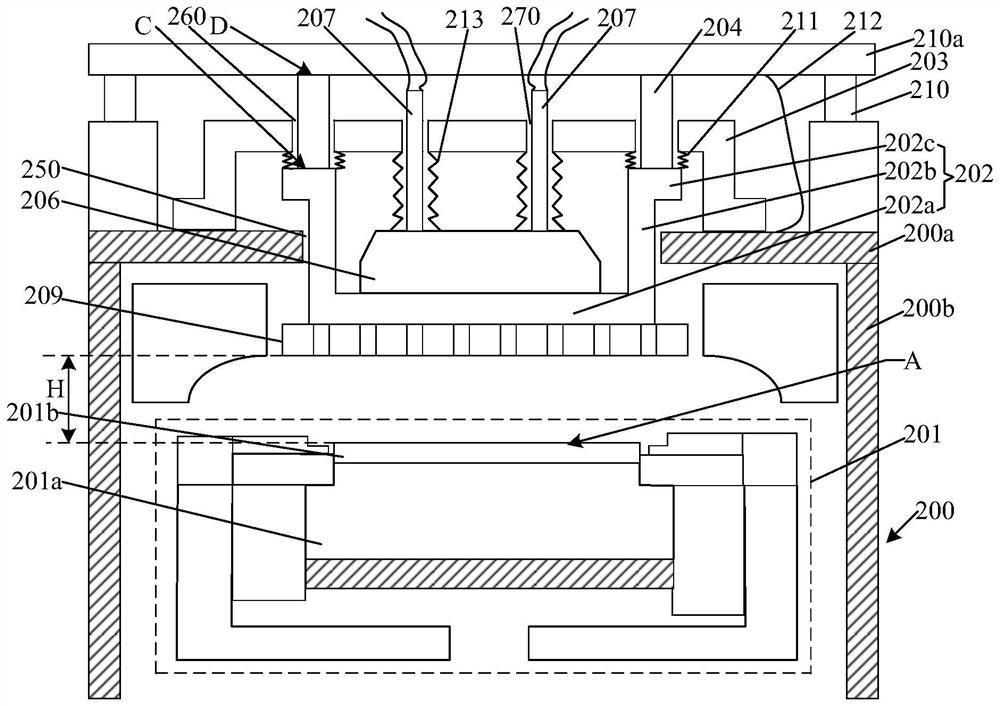

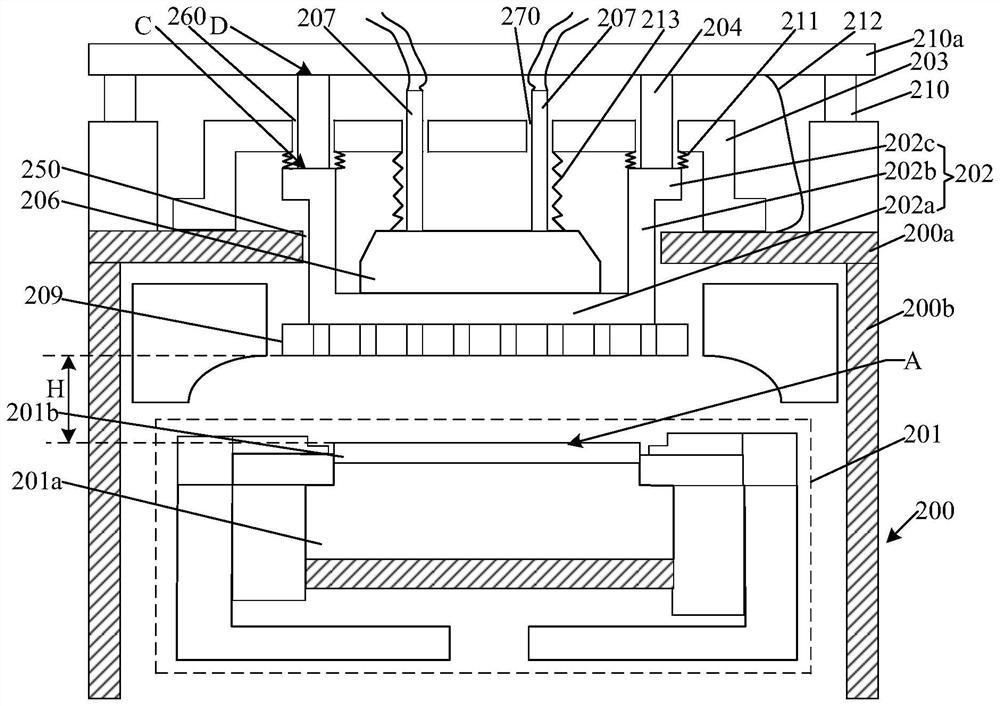

[0028] In order to solve the above technical problems, the technical solution of the present invention provides a plasma etching device, which can linearly adjust the distance between the upper electrode assembly and the lower electrode assembly to meet the needs of different processing techniques. Specifically, a plasma etching equipment, comprising: a reaction chamber, the top of the reaction chamber has a first opening; a lower electrode assembly located at the bottom of the reaction chamber, the lower electrode assembly includes a bearing surface, the The carrying surface is used to carry the substrate to be processed; the mounting substrate located in the first opening, there is a gap between the mounting substrate and the side wall of the first opening; the fixing part located at the top of the reaction chamber, the fixing The portion surrounds the mounting substrate, and the fixing portion has a second opening; the connecting portion, the connecting portion passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com