Denitration and ammonia spraying control system for W-flame boiler and method thereof

A control method, boiler technology, applied in the direction of control/regulation systems, separation methods, flow control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

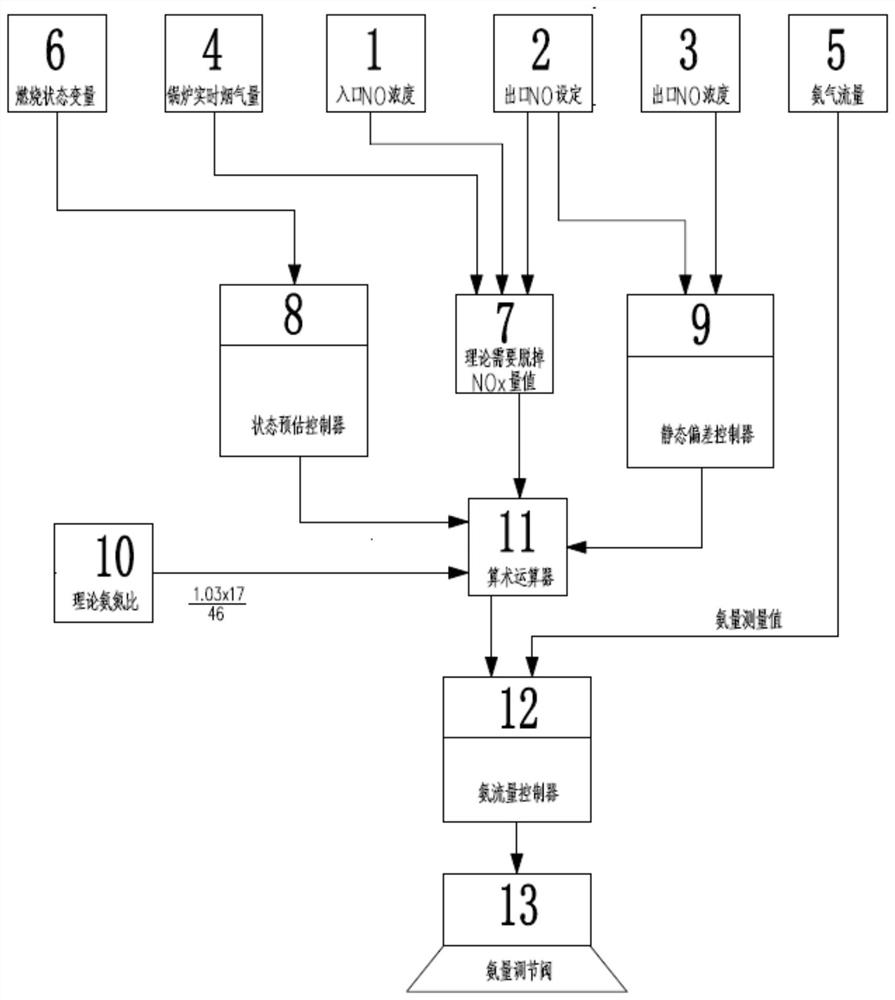

[0027] refer to figure 1 , the W flame boiler denitration ammonia injection control system of the present invention includes SCR inlet NO x Concentration module 1, SCR outlet NO x Concentration setting module 2, SCR outlet NO x Concentration module 3. Boiler real-time flue gas flow calculation module 4. Ammonia flow module 5. Boiler combustion state variable module 6. NO that needs to be removed theoretically x Quantity module 7, combustion state estimation controller 8, static deviation controller 9, theoretical ammonia nitrogen molar ratio module 10, arithmetic operator module 11, ammonia flow controller 12 and ammonia flow regulating valve 13. The ammonia gas flow module 5, the theoretical ammonia-nitrogen molar ratio module 10, the arithmetic operator module 11, the ammonia flow controller 12 and the ammonia flow regulating valve 13 form an "ammonia in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com