Wire rod transmission detection device

A transmission detection and wire technology, applied in transportation and packaging, transportation of filamentous materials, textiles, etc., can solve the problems of limited use, waste of wire, complex structure, etc., to achieve flexible and convenient use, accurate detection results, high adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, so that those skilled in the art can implement it with reference to the description.

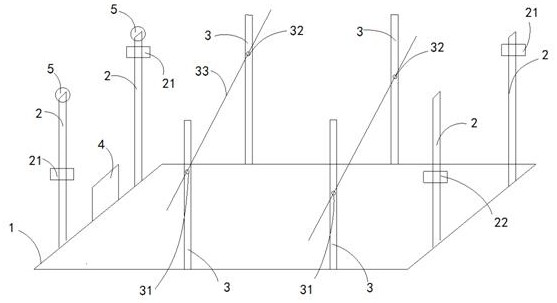

[0020] Such as figure 1 As shown, a wire transmission detection device includes: a fixed frame 1, on both sides of the fixed frame 1 there are several sets of adjustable first adjusting rods 2 symmetrically arranged to form several detection spaces, and the fixed frame 1 On the other two sides of the frame 1, there are several sets of adjustable second adjustment rods 3 arranged symmetrically, and the first adjustment rods 2 of each group are respectively provided with an infrared emitter 21 and an infrared light receiver 22. The second adjusting rod 3 has an inlet hole 31 and an outlet hole 32 correspondingly arranged for the wire to pass through; a wire transmission channel 33 is formed between each group of inlet holes 31 and outlet holes 32, so that the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com