Process and device for producing medium-high manganese steel plate strip

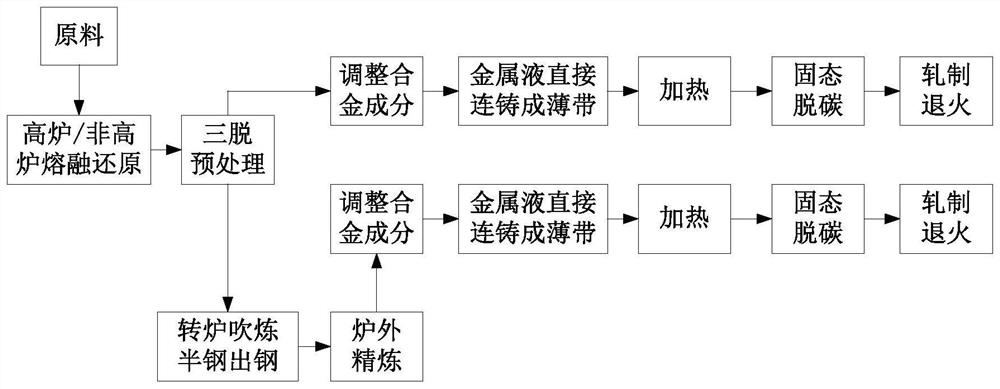

A steel strip and high-manganese technology, applied in the field of steelmaking and smelting control, can solve the problems of manganese macro-segregation affecting steel quality, etc., and achieve the effects of shortening the smelting process, reducing production costs, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A preparation process for medium manganese steel strips, using a blast furnace to produce molten iron, and then performing desulfurization, desiliconization, and dephosphorization pretreatments. After pretreatment, the carbon content is 3.5wt%. Adding ferromanganese alloy will adjust the alloy composition of the molten metal to the required requirements (As the manganese component is adjusted to 6wt%), the desired metal liquid is obtained.

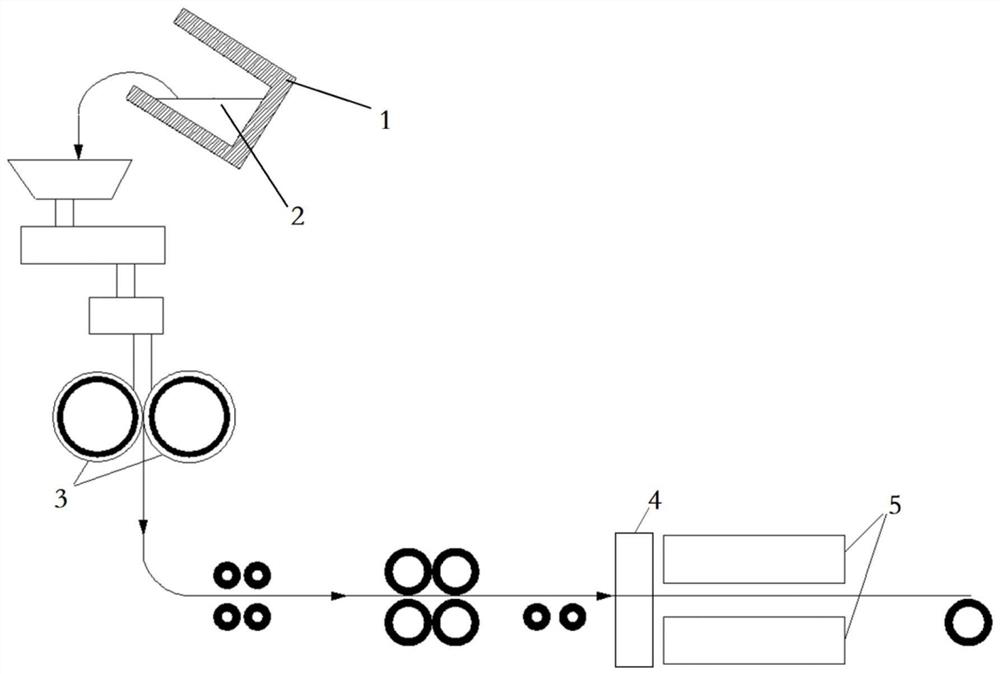

[0079] Step 1. The molten metal is directly poured into the twin-roll continuous casting equipment 3 through the molten metal ladle and solidified into a thin strip with a thickness of 3mm. The cooling intensity: 5000W / (m 2 k); casting speed 2m / min; pouring temperature 1700K.

[0080] Step 2. Heat the thin strip to 1415K by electromagnetic induction heating, and introduce a reducing atmosphere Ar-H in the electromagnetic induction heating device 2 , H 2 The volume content is 2%.

[0081] Step 3. The temperature of the controlled ...

Embodiment 2

[0084] In this embodiment, combined with the existing traditional converter steelmaking process, the tapping of converter is relaxed, and half-steel tapping of converter is used to shorten the converter blowing time (for example, the 120t converter smelting time is shortened from 40 minutes to 15-25 minutes).

[0085] A preparation process of medium manganese steel strip, using non-blast furnace smelting reduction to produce molten iron, then performing desulfurization, desiliconization, dephosphorization pretreatment, the carbon content after pretreatment is 3.5wt%, and then carrying out converter blowing, partial decarburization, The semi-steel is tapped, and then refined outside the furnace to adjust the alloy composition to the required requirements to obtain the required molten metal (the carbon content at this time is 1.5wt%, and the manganese composition is adjusted to 20wt%).

[0086] Step 1. The molten metal is directly poured into the twin-roll continuous casting equi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com