Processing method of high-color-purity natural brown cotton antibacterial yarn

A processing method, brown cotton technology, applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of pigment loss, difficulty in practical use, and affecting the antibacterial performance of colored cotton products, so as to suppress yellow light, low processing cost, and improve color purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

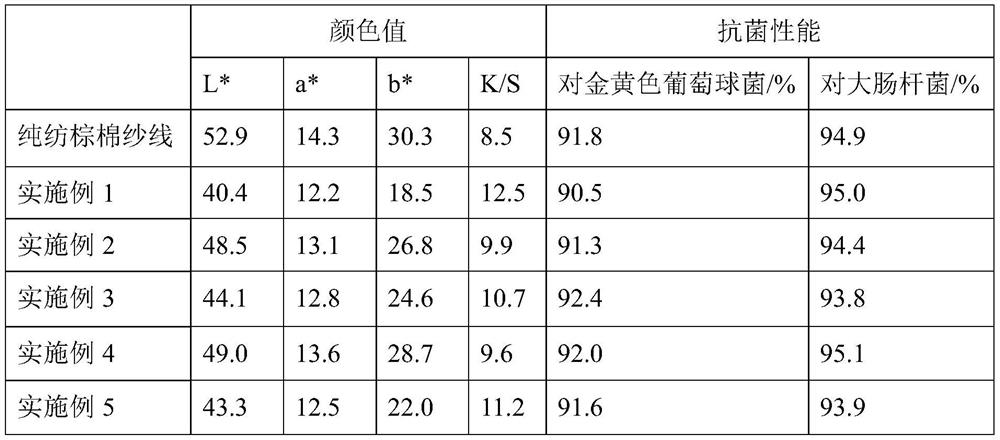

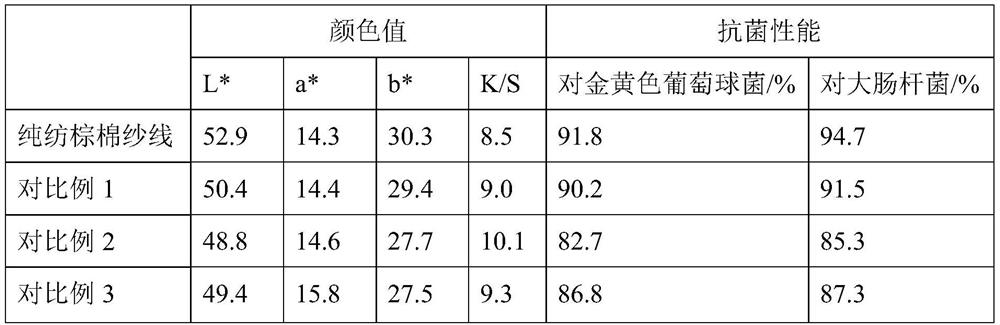

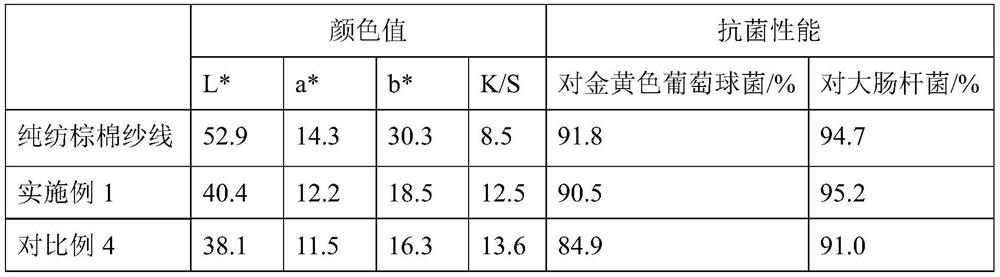

Examples

Embodiment 1

[0025] Embodiment 1, a kind of processing method of high color purity natural brown cotton antibacterial yarn, carries out following steps successively:

[0026] 1) Preparation of dyed cotton fibers: white cotton fibers were placed in natural indigo dyeing liquor at a temperature of 50°C at a bath ratio of 1:150, and the dyeing time was 30 minutes. The dyeing liquor contained 1.2 g / L natural indigo dye, 8.0 g / L L of NaOH, 10.0g / L of sodium hydrosulfite. After dyeing, wash off the floating color of the fiber with water (until the eluate is colorless), and dry at 50° C. (until constant weight) to obtain dyed cotton fiber.

[0027] The color values of the obtained dyed cotton fibers are: L*=22, a*=52, b*=-105.

[0028] 2) Spinning: first prepare natural brown cotton and dyed cotton fibers according to the mass percentage of 92:8, and then carry out the following procedures in sequence: combing → mixing wet → opening → carding machine → drawing frame → roving frame → spinning f...

Embodiment 2

[0030] Embodiment 2, a kind of processing method of high color purity natural brown cotton antibacterial yarn, carry out following steps successively:

[0031] 1) Preparation of dyed wool fiber: place the wool in a natural indigo dye solution at a temperature of 50°C at a liquor ratio of 1:100, and the dyeing time is 60 minutes. The dye solution contains 1.8g / L natural indigo dye, 1.5g / L L penetrant JFC, 1.5g / L penetrant Pingping plus O, 1.0g / L Yuanming powder. After dyeing, wash the fiber with water to remove floating color, and dry it at 50°C to obtain dyed wool fiber.

[0032] The color values of the obtained dyed wool fiber are: L*=45, a*=66, b*=-68.

[0033] 2) Spinning: firstly prepare natural brown cotton and dyed wool fiber according to the mass percentage of 99:1, and then carry out the following procedures in sequence: combing→mixing and wetting→opening→carding machine→drawing frame→roving frame→spinning frame → Winding process to obtain a blended yarn with a lin...

Embodiment 3

[0034] Embodiment 3, a kind of processing method of high color purity natural brown cotton antibacterial yarn, carries out following steps successively:

[0035] 1) Preparation of dyed spun silk fiber: the spun silk is placed in the reactive blue 2 dyeing solution with a bath ratio of 1:50 at a temperature of 60° C., and the dyeing time is 90 minutes. The dyeing solution contains 1.2 g / L reactive blue 2 dye, 2.0g / L penetrating agent JFC, 1.5g / L leveling agent Pingping plus O. After dyeing, wash the floating color of the fiber with water, and dry it at 50°C to obtain dyed spun silk fiber.

[0036] The color values of the obtained dyed spun silk were: L*=34, a*=53, b*=-89.

[0037] 2) Spinning: first prepare natural brown cotton and dyed spun silk fibers according to the mass percentage of 97:3, and then carry out the following procedures in sequence: combing → mixing wet → opening → carding machine → drawing frame → roving frame → spinning Machine→winding process to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com