Socket and spigot type flexible connector reinforced concrete drainage pipe and machining process thereof

A reinforced concrete, flexible interface technology, applied in rigid pipes, pipes/pipe joints/fittings, pipes, etc., can solve the problems of insufficient bearing capacity, leakage of sewage from drainage pipes, and insufficient connection, so as to improve the anti-corrosion ability, increase the The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

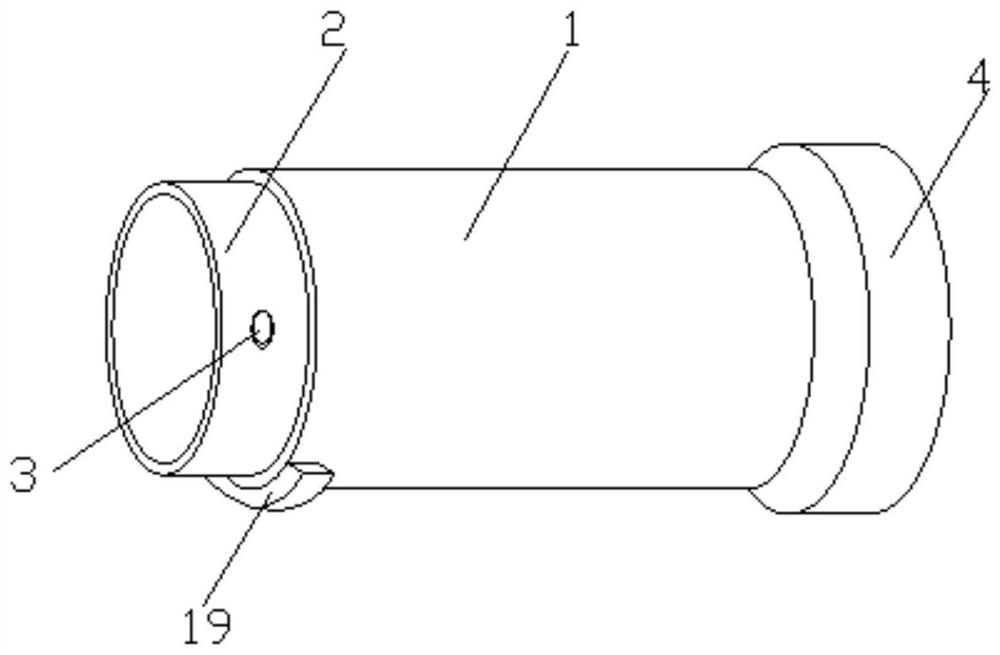

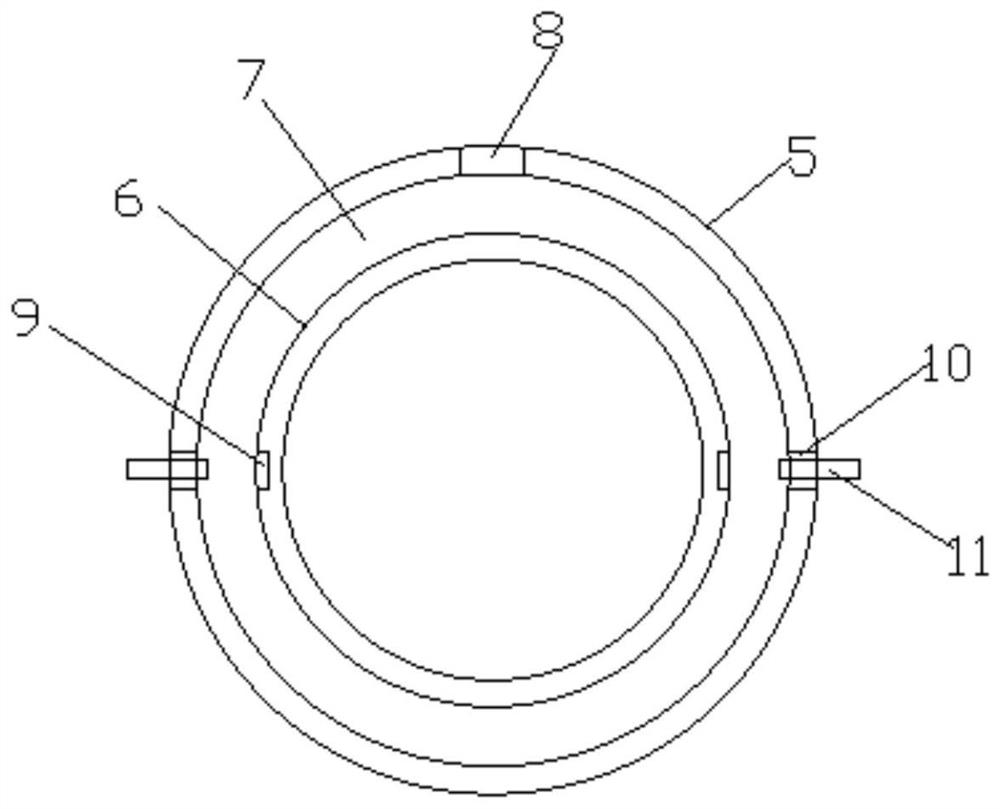

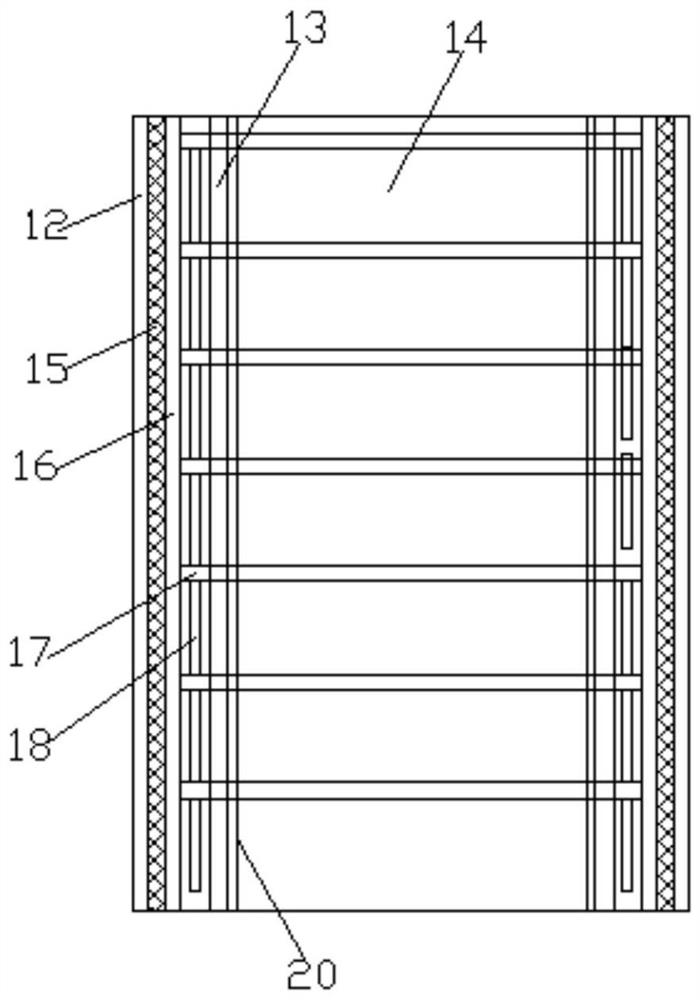

[0036] see Figure 1-3 , according to an embodiment of the present invention, a socket-type flexible interface reinforced concrete drainage pipe and its processing technology include a drainage pipe body 1, one end of the drainage pipe body 1 is provided with a pipe interface 2, and the pipe interface 2 Positioning through holes 3 are provided on both sides of the drainage pipe body 1, and the end of the drain pipe body 1 away from the pipe interface 2 is provided with a pipe connection structure 4. The pipe connection structure 4 includes an outer connection ring 5 and an inner connection ring 6. Between the outer connecting ring 5 and the inner connecting ring 6, a connecting circular groove 7 matching the pipe interface 2 is formed, and the top of the outer connecting ring 5 is provided with a concrete pouring port 8, and the inner connecting ring 6 Positioning grooves 9 are provided on both sides of the outer connecting ring 5, and insertion holes 10 are provided on the sa...

Embodiment 2

[0047] like Figure 1-3 As shown, the drainpipe body 1 is provided with a balance base 19 below one end of the pipe interface 2, which can ensure the balance of the drainpipe body 1 after installation; the inner wall of the inner concrete cylinder 13 It is provided with an anti-corrosion interlayer 20 to improve the anti-corrosion ability of its surface and increase its service life; in the step 7, after the drain pipe is demoulded, its surface needs to be wiped to ensure that its surface is smooth; the outer connecting ring 5 A waterproof gasket is arranged between the bottom of the inner connection ring 6 to improve the sealing of the joint.

[0048] In order to facilitate the understanding of the above-mentioned technical solution of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0049] In actual application, when in use, insert the pipe joint 2 at one end of the drainpipe i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com