Device and method for geometric accuracy measurement and error compensation of dicing saw

A geometric accuracy and error compensation technology, which is applied in the field of geometric accuracy measurement and error compensation devices of dicing machines, can solve problems such as dial gauge hysteresis, and achieve the effect of meeting cutting requirements and high reference accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

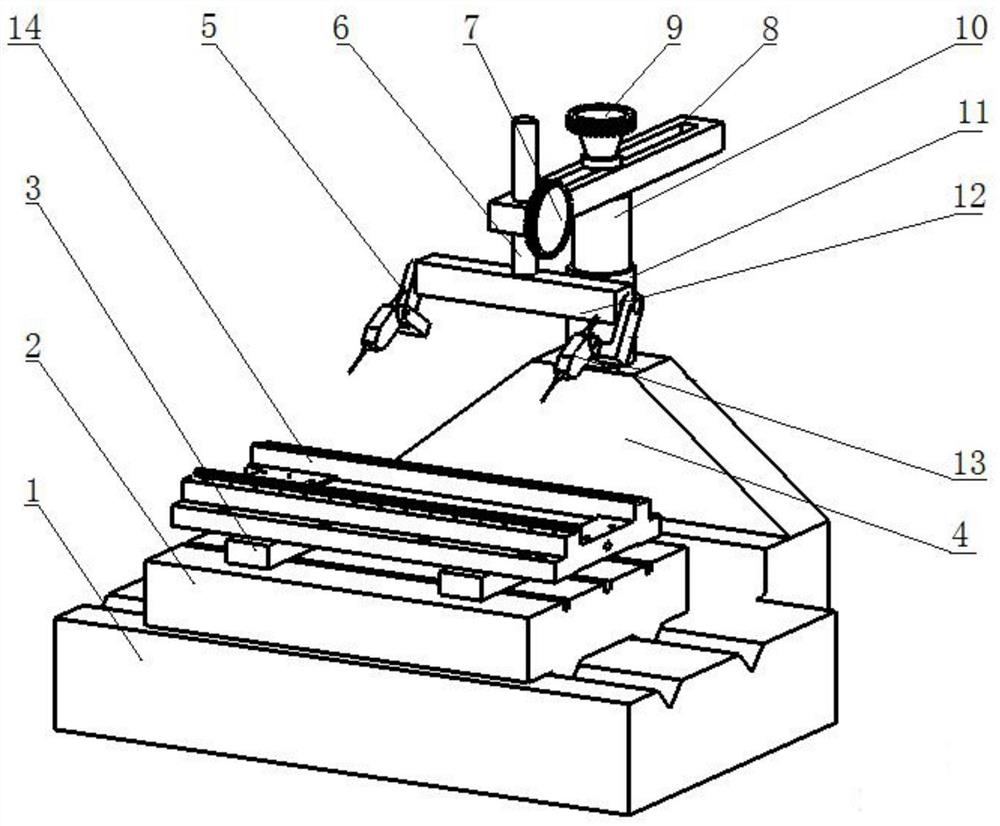

[0026] The invention provides a device for geometric accuracy measurement and error compensation of dicing machine, see figure 1 , including: grinding base 1, mobile platform 2, cushion block 3, support frame 4, connecting arm 5, lifting rod 6, lifting fixed wheel 7, front and rear cantilever 8, cantilever pressing wheel 9, lifting guide column 10, fixed guide sleeve 11. Horizontal connecting arm 12 and electronic micrometer 13;

[0027] One side of the top of the grinding base 1 is provided with a support frame 4, and the other side is provided with a groove, and the groove is parallel to the support frame 4; the mobile platform 2 is arranged on the side with the groove on the top of the grinding base 1, and the mobile platform The bottom of 2 is provided with a protrusion, and the protrusion is matched with the groove; a pad 3 is provided on the mobile platform 2;

[0028] The support frame 4 is provided with a fixed guide sleeve 11, and the lifting guide column 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com