Offshore hoisting operation risk evaluation method based on analog simulation system

A technology for simulating and hoisting operations, applied in resources, instruments, data processing applications, etc., can solve problems such as logic uncertainty and data incompleteness, achieve comprehensive and accurate identification, strong objectivity and scientificity, and avoid Effects of subjectivity and the limitations of cognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

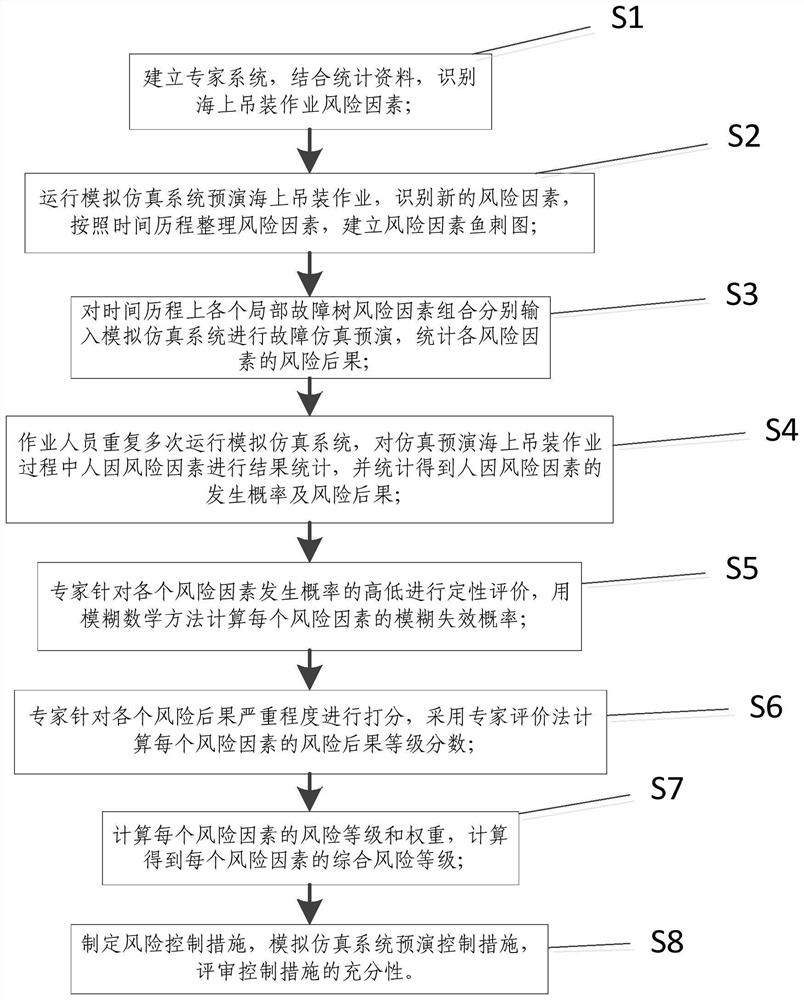

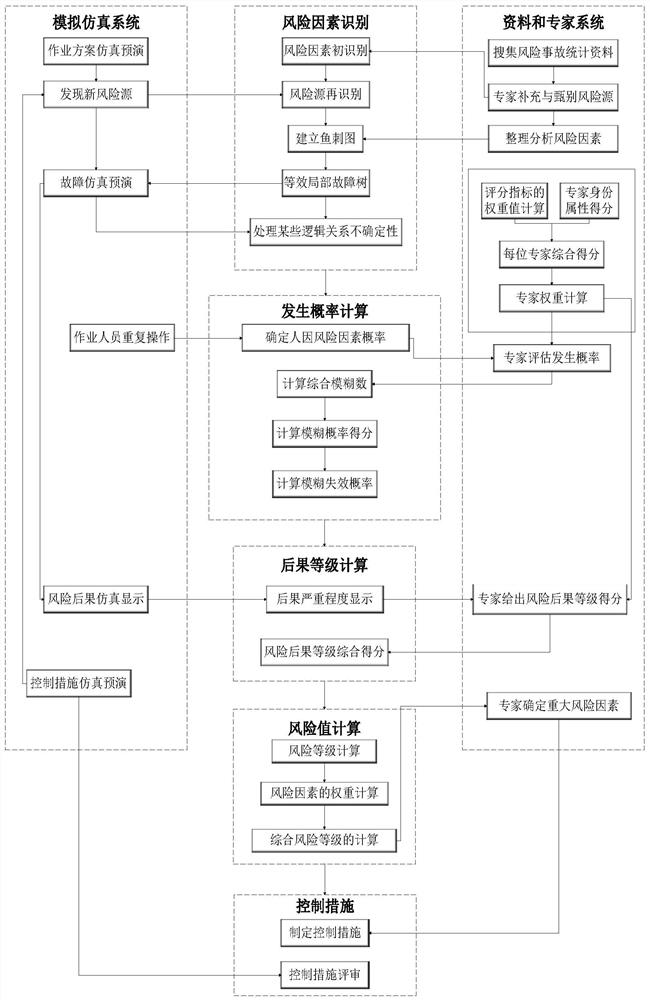

[0057] figure 1 It is a flow chart of the risk assessment method for offshore hoisting operations based on the simulation system of the present invention, such as figure 1 As shown, the present invention provides a method for risk assessment of offshore hoisting operations based on a simulation system, which includes the following steps:

[0058] S1: Establish an expert system and combine statistical data to identify risk factors for offshore hoisting operations;

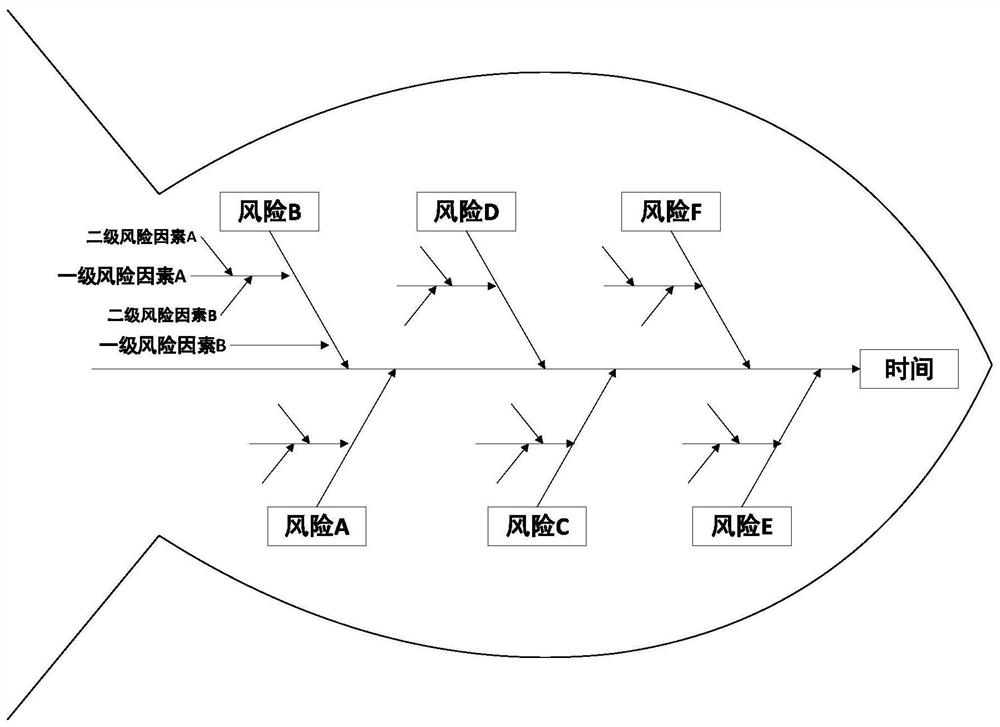

[0059] S2: Run the simulation system to preview offshore hoisting operations, identify new risk factors, sort out risk factors according to time history, and establish risk factor fishbone diagrams;

[0060] S3: Input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com