Straight cylinder shell and double-color injection mold thereof

A two-color injection molding, shell technology, applied in electrical equipment shell/cabinet/drawer, chassis/box/cabinet/drawer parts, electrical components, etc., can solve problems such as insufficient stability, improve production efficiency, structural design Reasonable and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

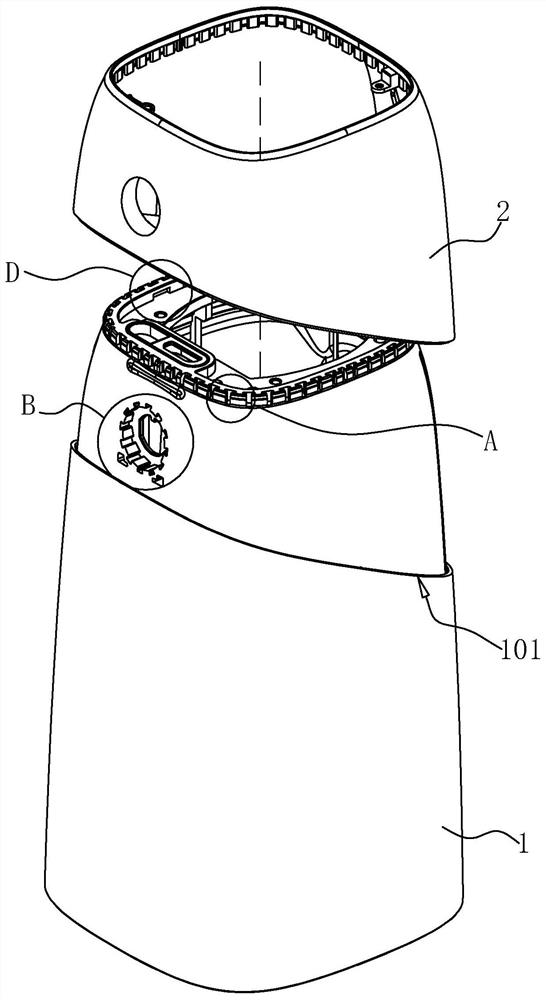

[0052] The following is attached Figure 1-21 The application is described in further detail.

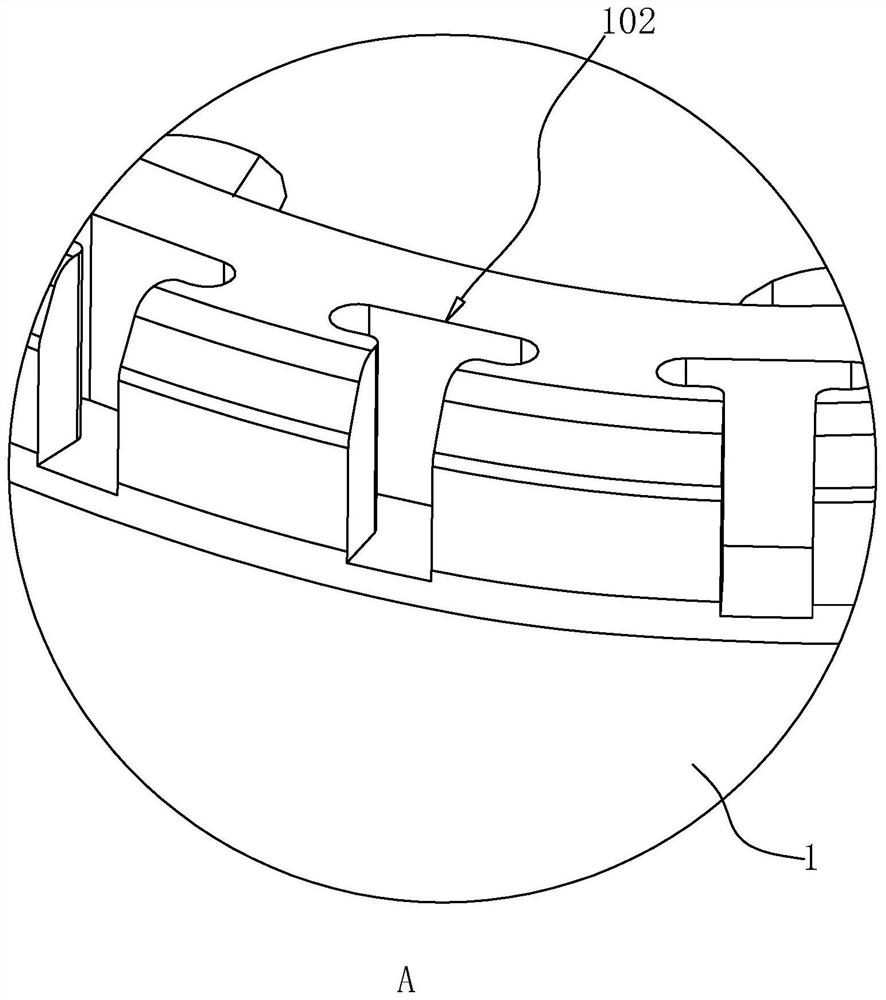

[0053] The embodiment of the present application discloses a straight shell, referring to figure 1 and figure 2 , the workpiece includes a body part 1 and a two-color layer 2. The body part 1 is arranged in a straight cylindrical shape. The interior of the body part 1 is hollow and has openings at both ends. The body part 1 can be injection molded with a hard ABS material. The body part 1 is used for For electronic components to install. In addition, the two-color layer 2 is sleeved on the body part 1, and the outer surface of the body part 1 is recessed to be provided with an accommodating groove 101 for the two-color layer 2. Under the action of the accommodating groove 101, the surface of the two-color layer 2 and the The surface of the body part 1 is flush, wherein the body part 1 and the two-color layer 2 are integrally connected to each other, and when the two-color layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com